Menu

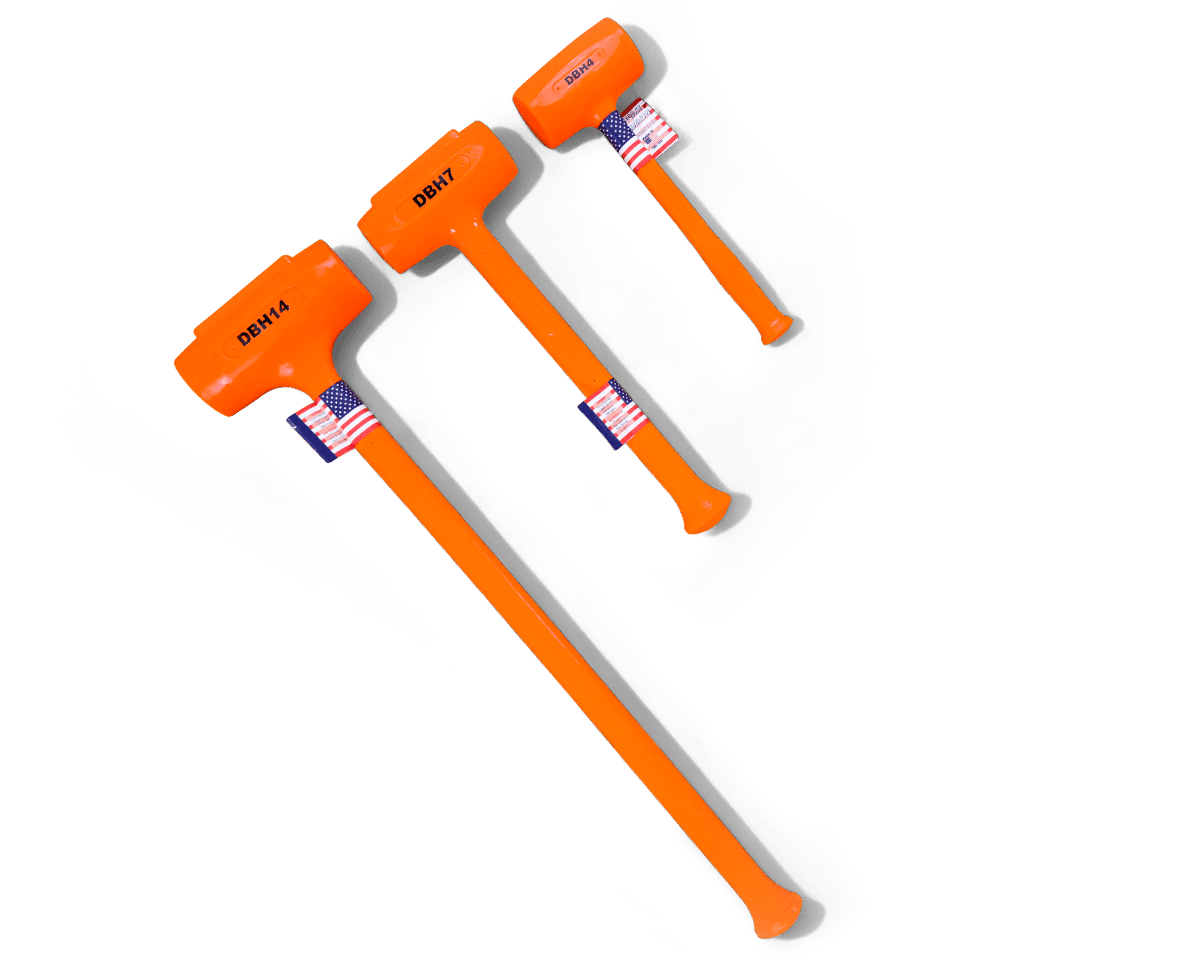

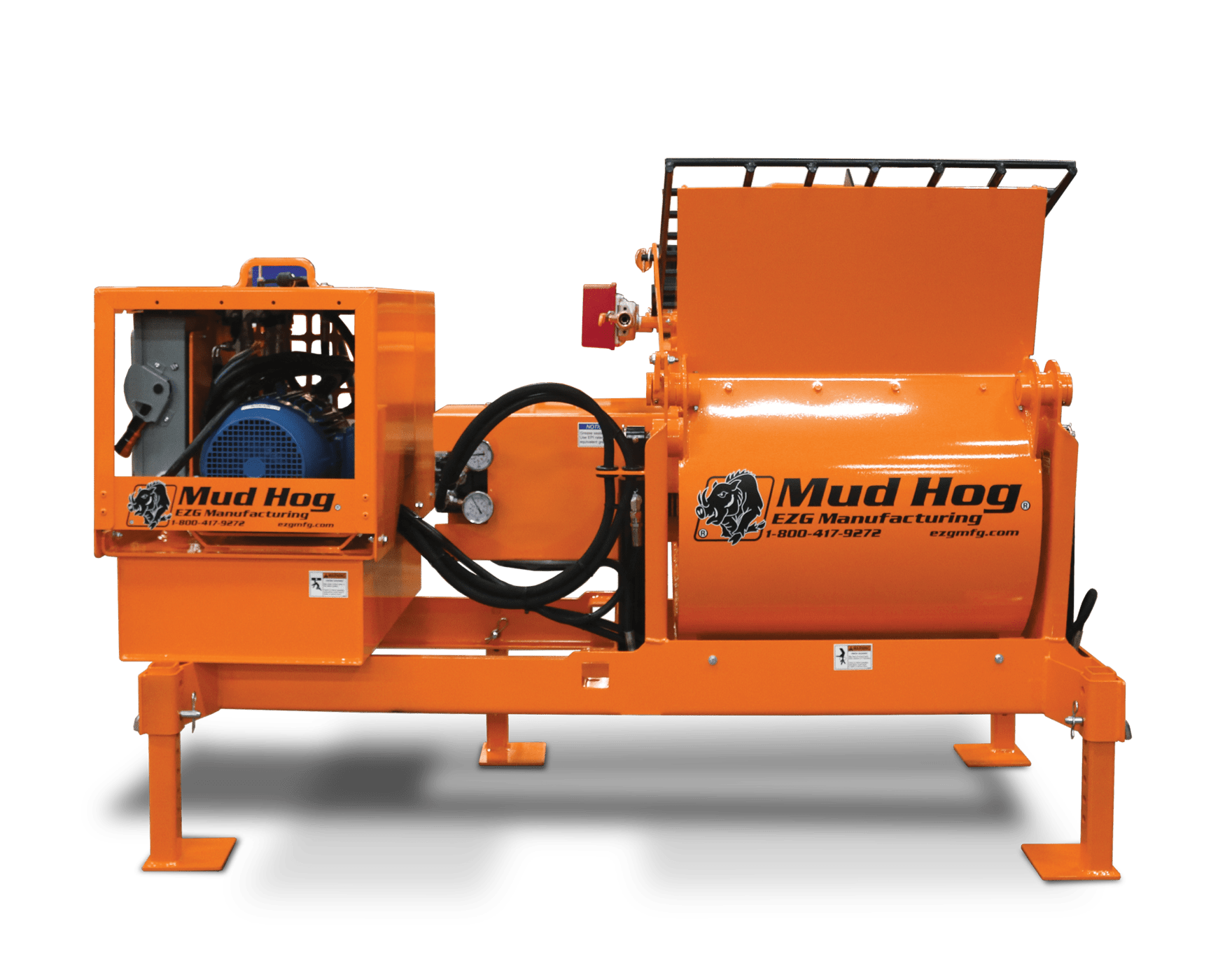

Masonry

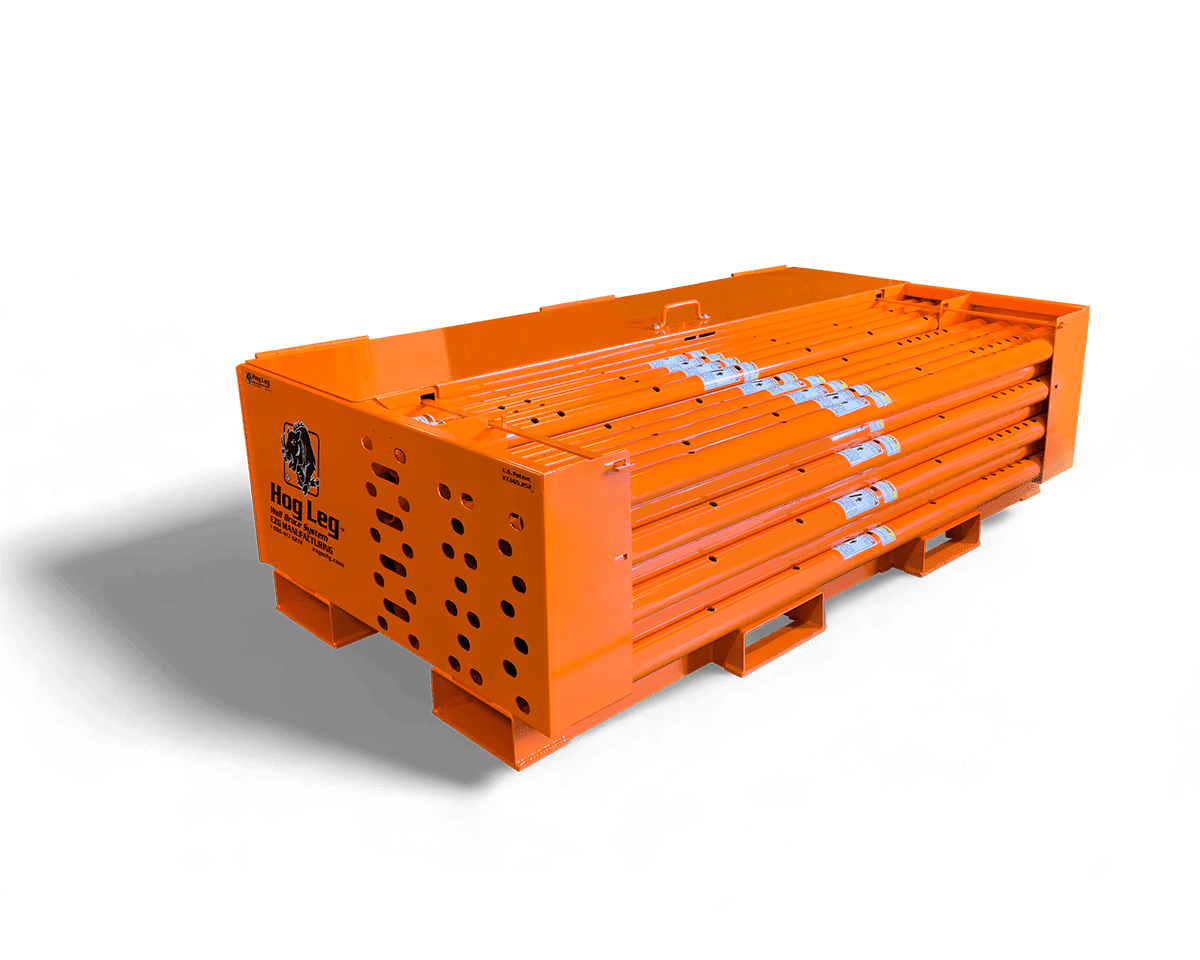

Fencing

- 36″ Fence Hog Extensions

FH36-4xFH36-2x

- 24″ Fence Hog Extensions

FH24-4xFH24-2x

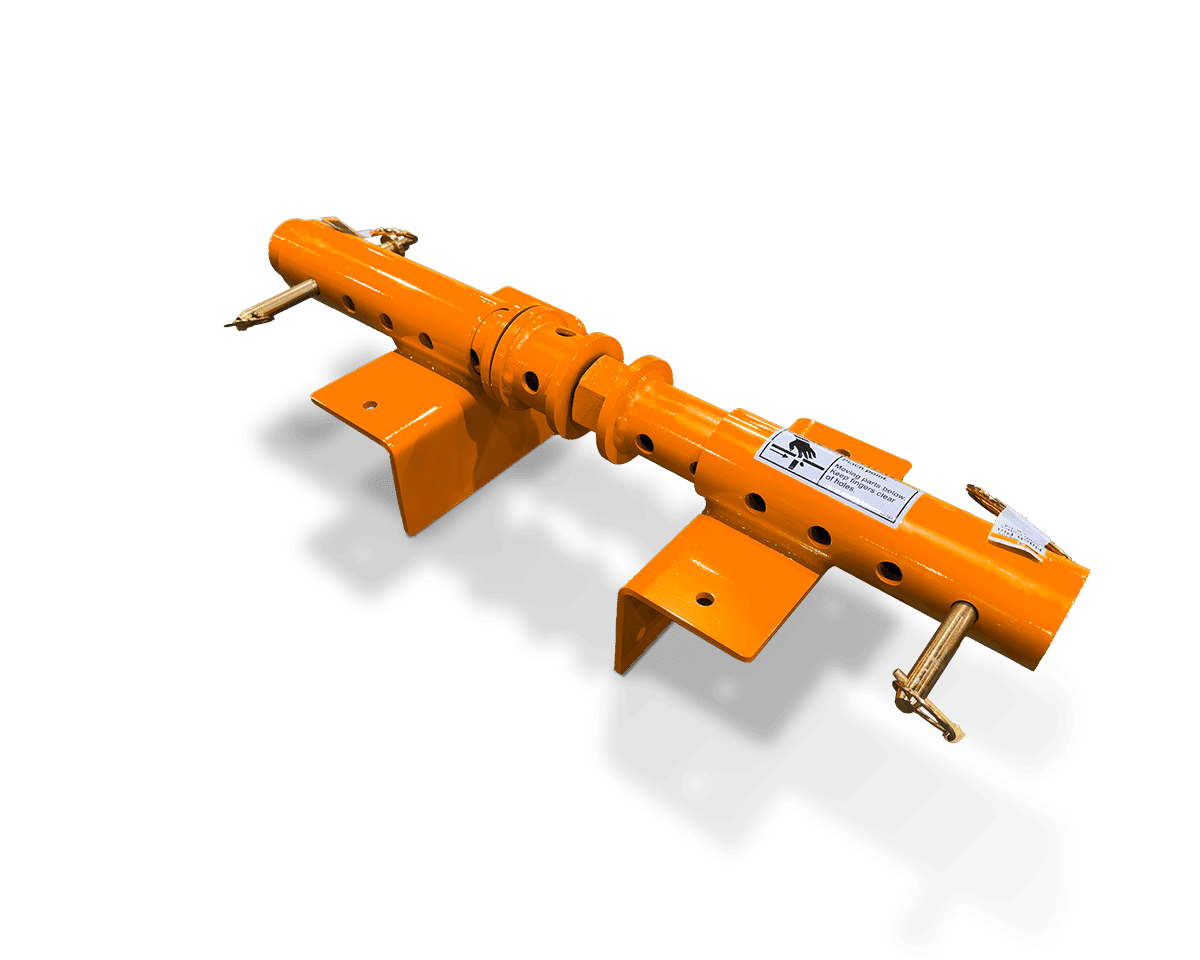

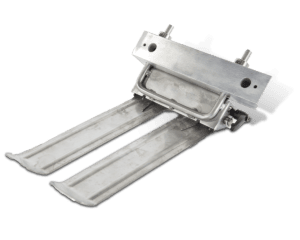

- Fence Hog Woven Wire Stretcher Arm

FHWS99-36FHWS99-24

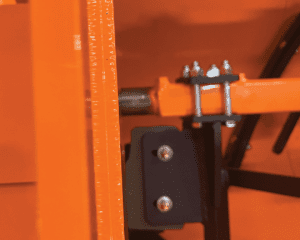

- Fence Hog Tilt Plate

TILTTA-A-18TA-A-20TA-A-21

- Fence Hog Universal Skid-Steer Plate

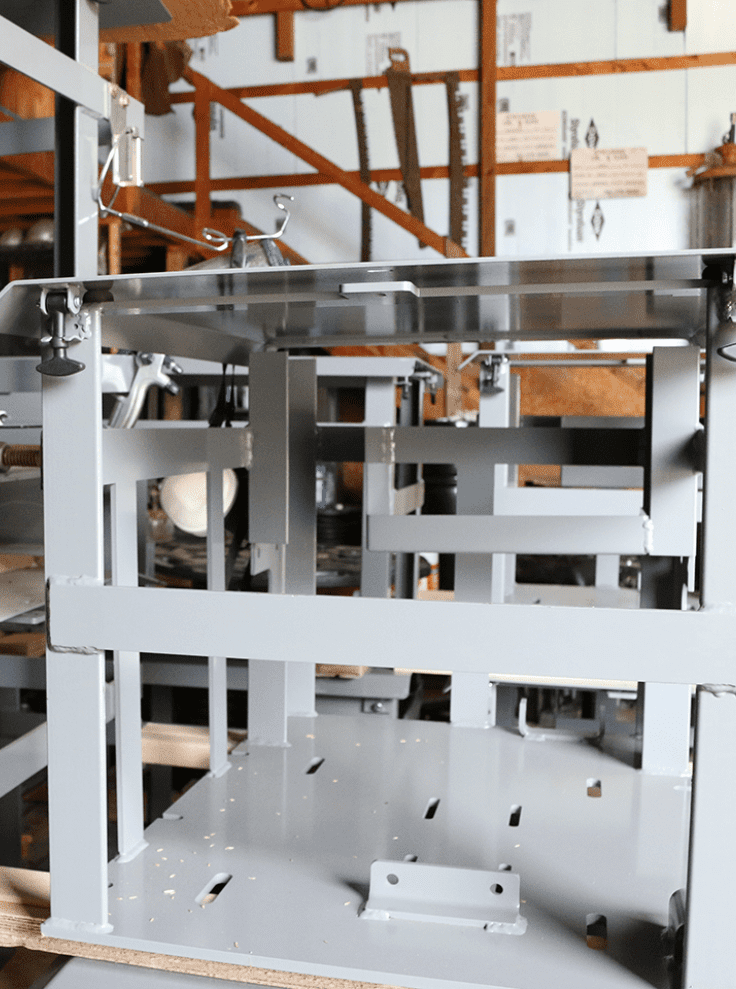

- Fence Hog Work Platform

FHWP

- Mini Fence Hog Plates

TILT-FHWFHW-A-10FHW-A-9

- Hog Hanger

HANGER

- Fence Hog Stringer

STRINGER

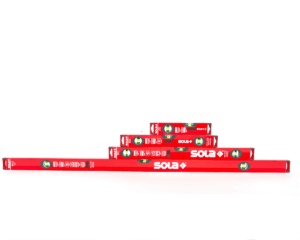

Hardscape

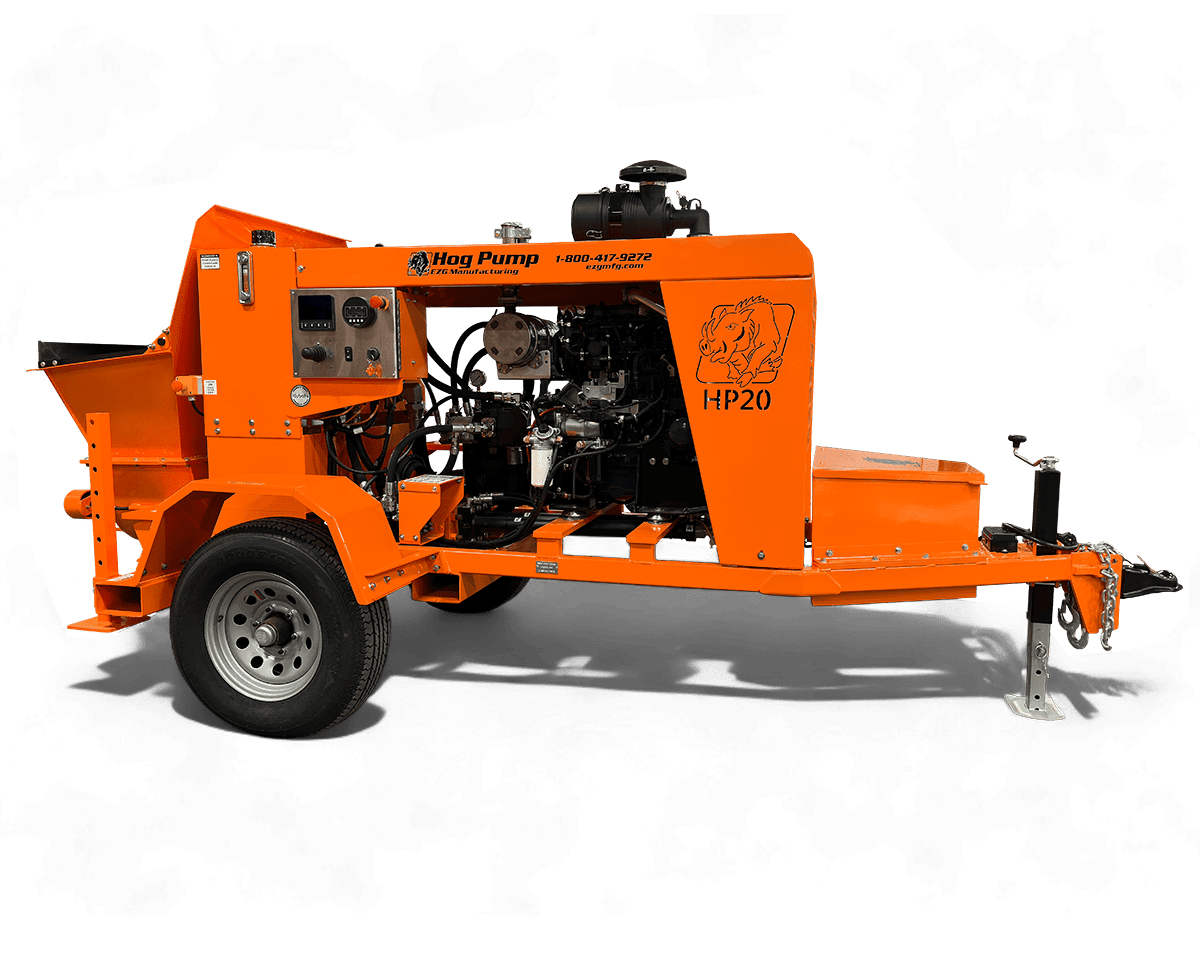

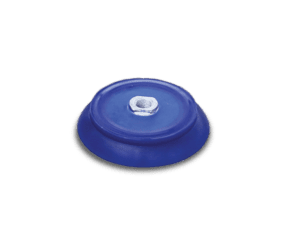

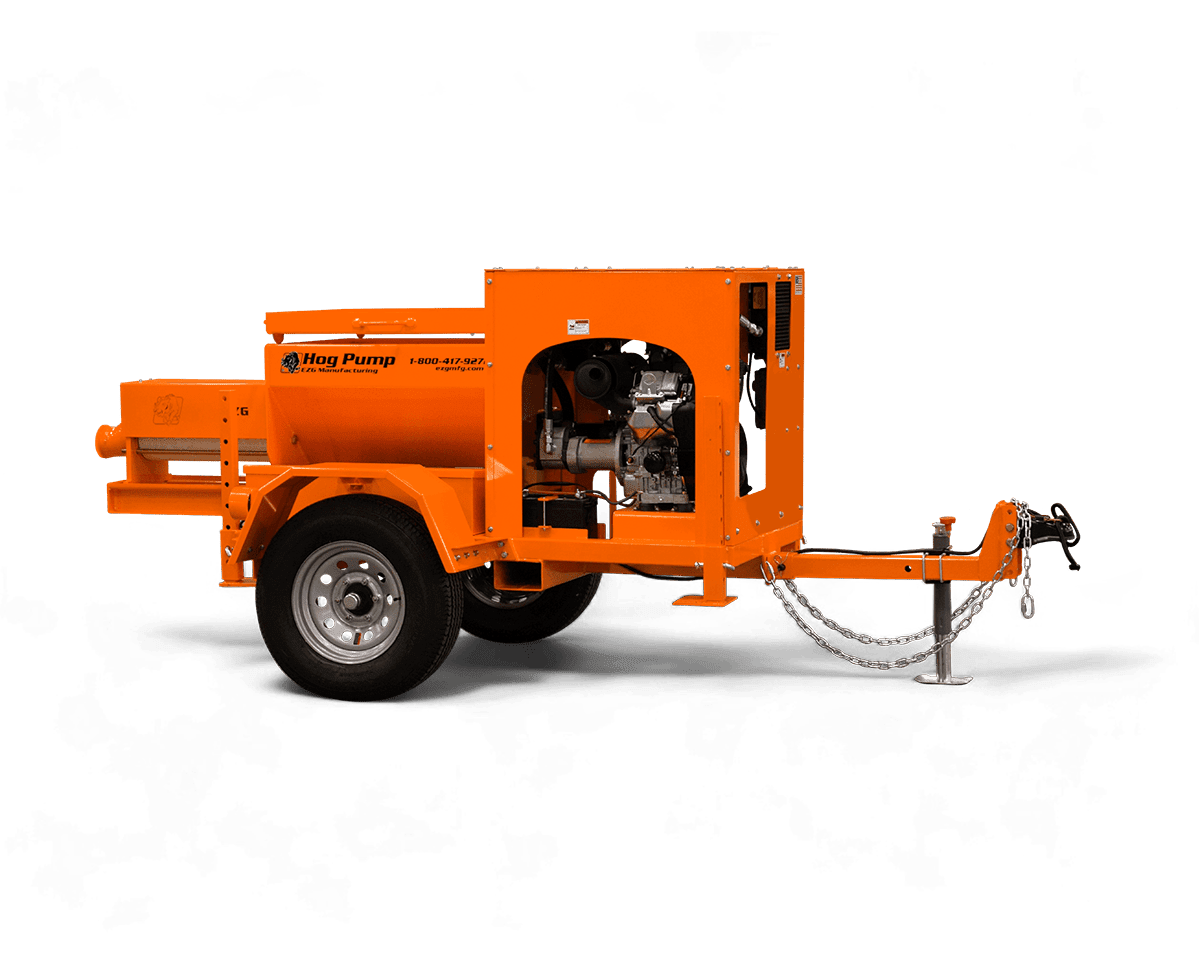

Pumps

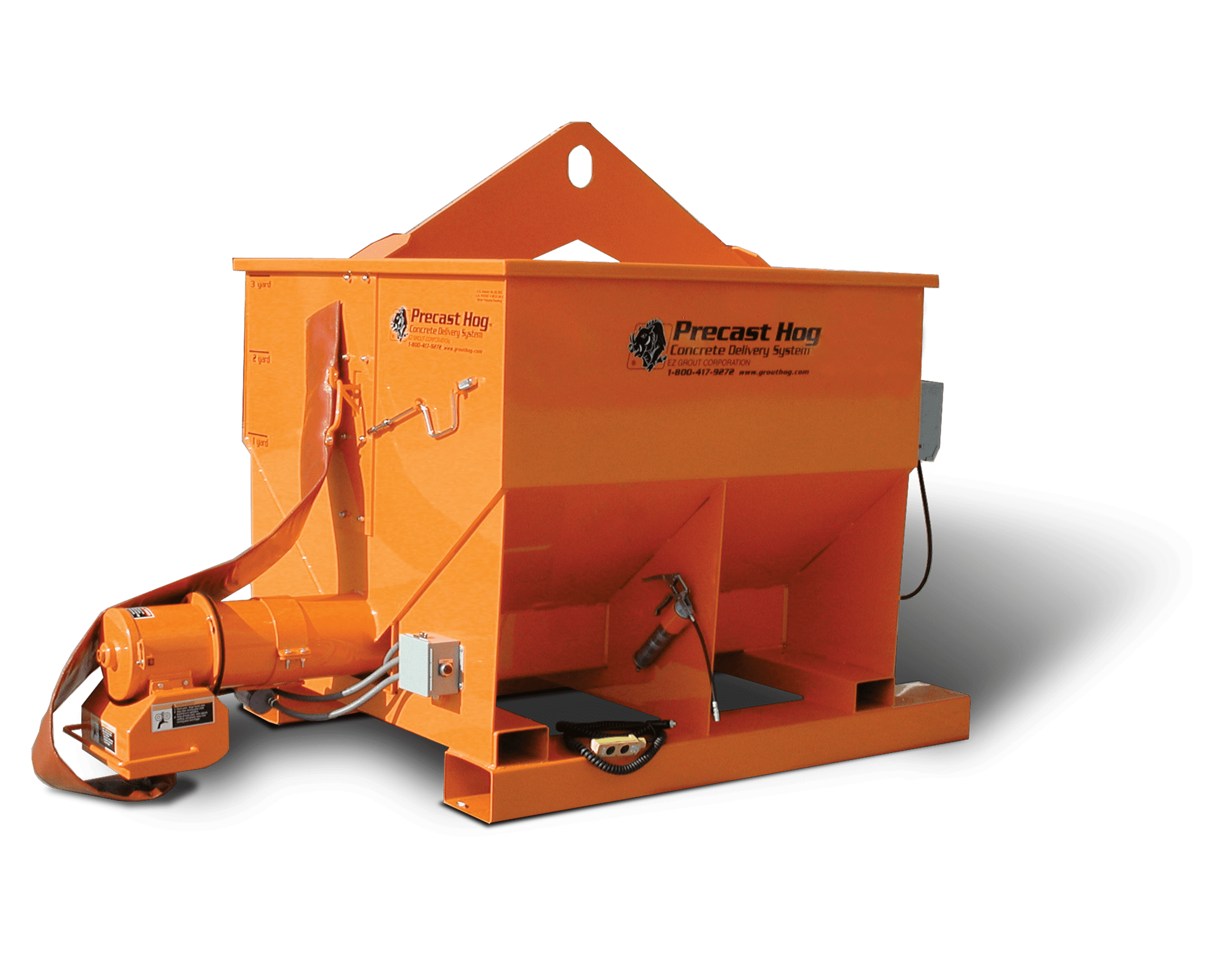

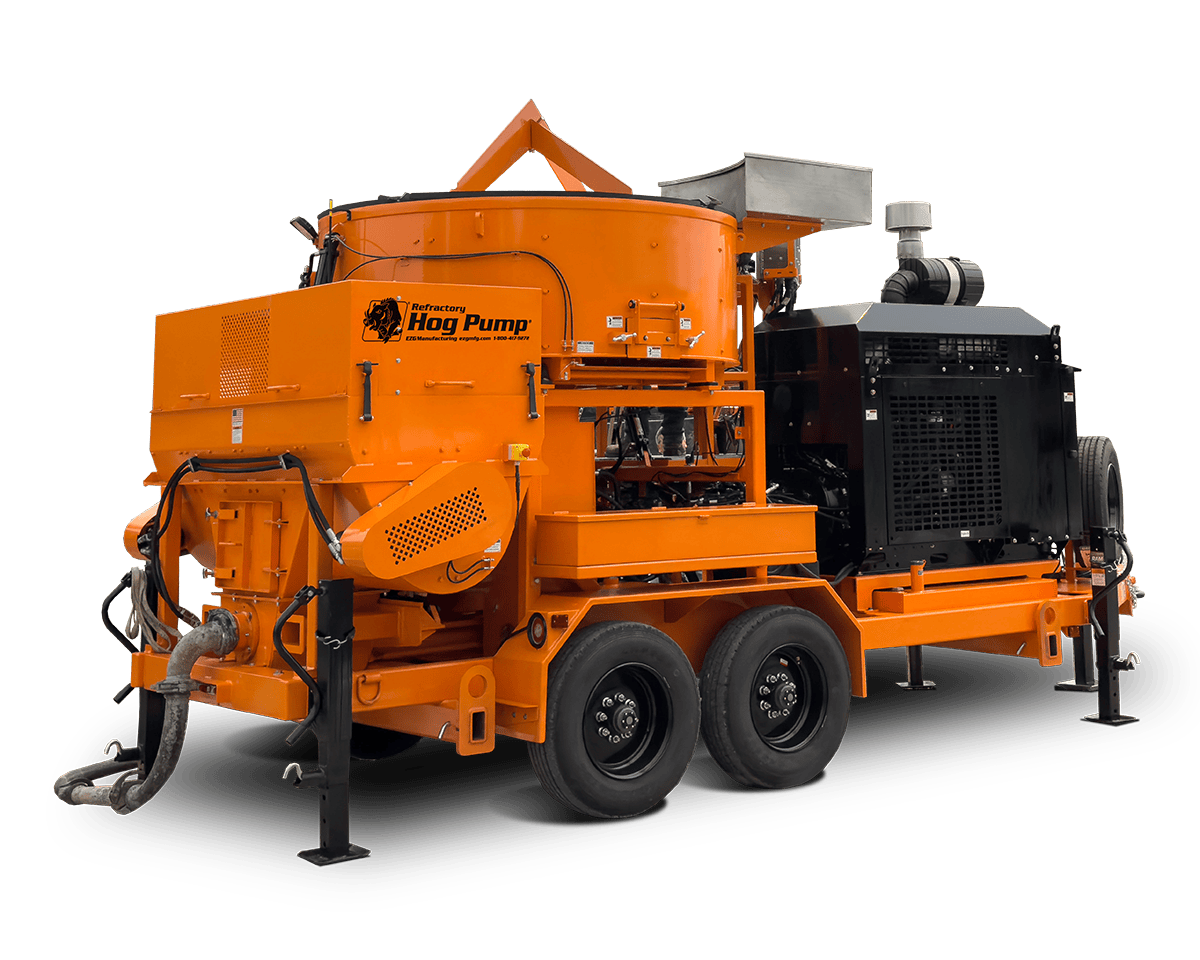

Precast / Refractory

INDUSTRIES

Menu

Watch Video

Hear from our leadership, see our shop and discover why our customers…

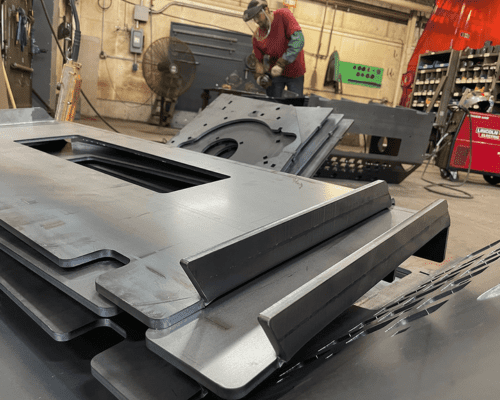

CAPABILITIES

Menu

Watch Video

Bringing our client’s vision to life with state-of-the-art equipment and precision craftsmanship…

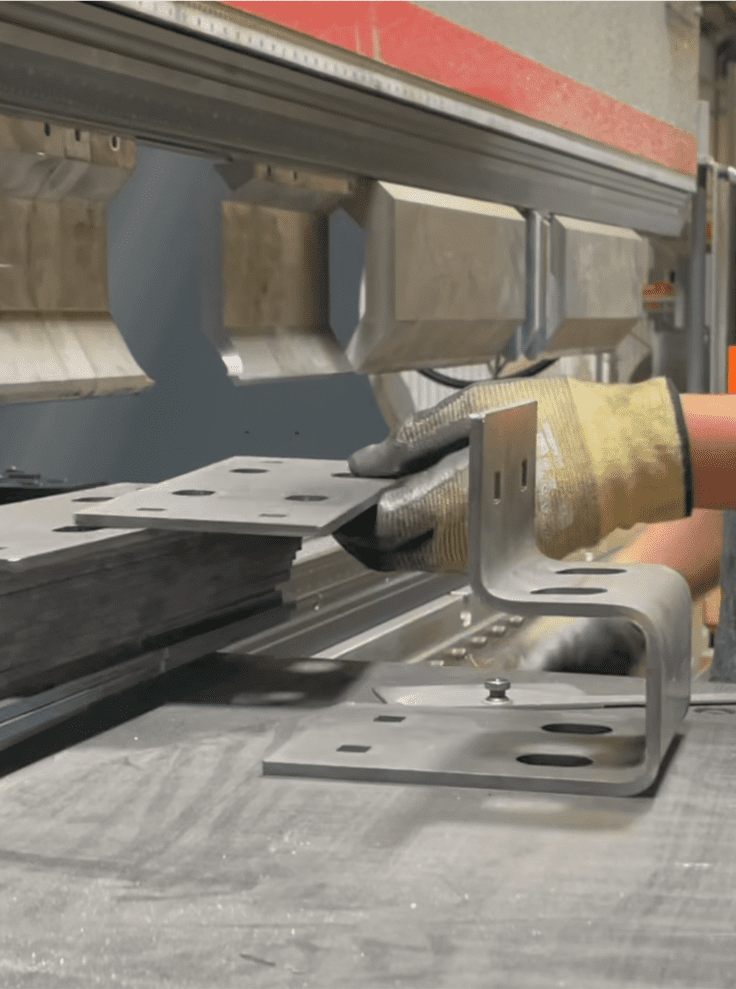

EQUIPMENT

Menu

Watch Video

What you can find on any given day in our 120,000 sq.ft. production facility…

EXPERTISE

Menu

Watch Video

Get to know Bruce Mattioda, EZG Manufacturing Shop Sales Rep.