A weld is like a handshake: it instantly tells you if it’s firm, reliable, or weak. When metal pieces are joined, the weld line reveals the skill of the welder, the quality of the technique, and the durability of the finished product. A high-quality weld holds strong under pressure, while a poor weld may crack, corrode, or fail when it matters most.

What is Welding? Why Welding Quality Matters

Welding is the process of joining metal pieces by applying heat, pressure, or filler material to create a solid bond. It’s more than just melting two surfaces together. It’s about forming a connection that can withstand stress, vibration, and long-term use.

When welding quality is high, the finished structure performs as intended. A strong weld adds durability and stability, while a poor weld weakens the entire assembly. In construction, that can mean compromised beams or structural joints. In automotive exhaust shops, it can result in leaks, cracks, or early breakdowns. In manufacturing, it leads to rework, wasted material, and costly downtime.

No matter the application, the strength of the weld determines the safety, reliability, and lifespan of the product.

What Makes a Good Weld?

The difference between a high-quality weld and a poor weld often comes down to details that an experienced eye can spot immediately. A good weld doesn’t just look clean; it performs under stress, resists wear, and extends the life of the finished product. It reflects the welder’s control over the welding process, the preparation of the base metal, and the correct use of filler material. Here are the traits you should expect to see in a quality weld:

- Uniform appearance: The weld bead should look smooth, even, and consistent.

- Adequate penetration: The weld must fully bond to the base metal, not just sit on the surface.

- Flat bead with distinct pattern: A visible but controlled ripple shows correct travel speed and technique.

- Clean surface: No porosity, cracks, or spatter around the bead.

- Strength without excess bulk: The weld adds stability without unnecessary buildup.

High-quality welds are confirmed through both visual inspection and advanced testing methods like ultrasonic testing. These checks confirm that the weld is bonded correctly through the base metal and is free of hidden flaws.

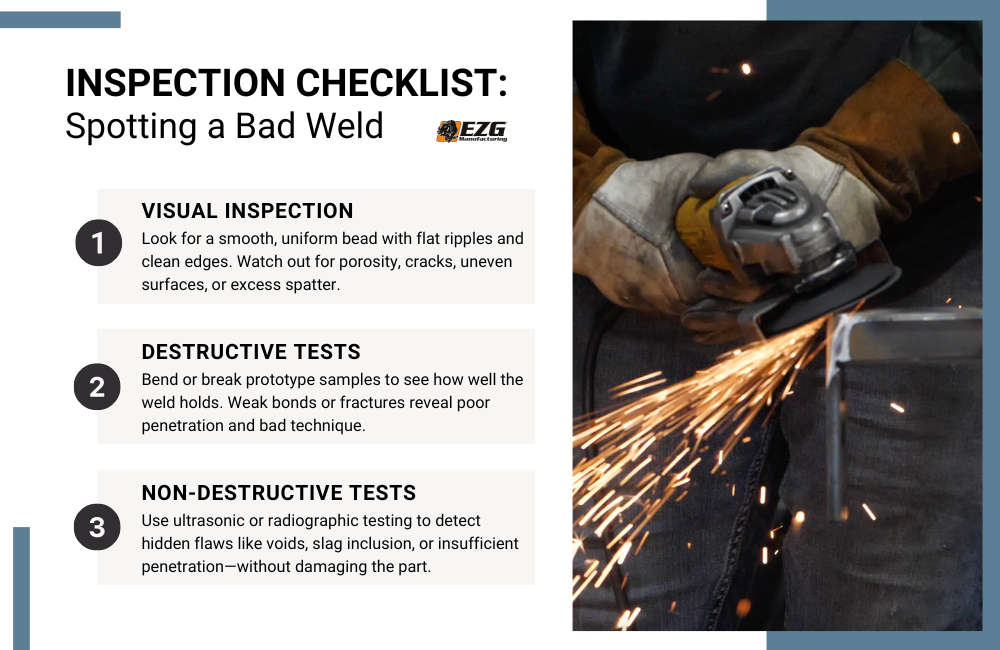

How to Check for a Bad Weld

Inspection is the most reliable way to separate strong, dependable welds from poor ones that could fail under pressure.

- Visual inspection: Start with the basics. A uniform weld bead, flat bead, and smooth finish are positive signs. On the other hand, porosity, spatter, cracks, or an uneven surface often point to a bad weld.

- Destructive tests (for prototypes): Bending or breaking samples is a direct way to test the weld’s strength and see how well it bonds the base metal.

- Non-destructive tests: Methods like ultrasonic testing and radiographic testing uncover hidden flaws such as voids or insufficient penetration without damaging the part.

In production environments, visual inspection is the first line of defense. For projects where safety and durability are critical, professional welders also rely on non-destructive testing to confirm weld strength before components go into service.

Signs You’re Looking at a Bad Weld

Bad welding is easy to spot once you know what to look for. Some defects are visible on the surface, while others weaken the structure from within. Each one signals a problem in the welding process and creates risks for the finished product.

Uneven Surface

A sloppy or inconsistent bead often signals poor technique or lack of control. Instead of forming a smooth, uniform appearance, the weld may rise and fall in thickness or wander off the joint line. This makes stress distribution uneven and increases the chances of cracking under load.

Insufficient Penetration

If the weld fails to bond deeply to the base metal, it will not hold under stress. On the surface, the bead may look acceptable, but the lack of proper penetration weakens the connection where strength matters most. This problem often shows up later, when the weld fails during use.

Slag Inclusion

Trapped filler material or foreign particles leave weak points in the weld. These inclusions interrupt the bond between the base metal and the filler metal, creating hidden voids. Over time, slag inclusions can lead to brittle fractures and are particularly dangerous in load-bearing parts.

Cracks or Porosity

Small holes, bubbles, or fractures create obvious weak spots. Porosity often comes from poor shielding gas coverage or contamination, while cracks usually result from rapid cooling or stress concentration. Both significantly reduce the weld’s durability and can quickly spread once the part is in service.

Undercutting

A groove along the weld toe reduces metal strength and creates stress points. This defect occurs when the welding arc melts away the base metal at the edges of the bead, leaving a sharp notch that acts as a natural starting point for cracks. Undercutting is especially dangerous in structural applications.

Excess Spatter or Contamination

Splatter around the weld line suggests incorrect settings or poor welding technique. While small amounts of spatter can be cleaned, excessive buildup weakens the surrounding metal and points to poor control of travel speed, wire feed, or shielding gas. Contamination from oil, dirt, or rust also prevents proper bonding.

| Defect | What It Looks Like | Why It’s a Problem |

|---|---|---|

| Uneven Surface | Sloppy, inconsistent weld bead; thickness varies | Causes uneven stress distribution and increases chances of cracking under load |

| Insufficient Penetration | Bead sits mostly on the surface, not fused into base metal | Weak joint that may fail when placed under pressure |

| Slag Inclusion | Dark spots or trapped material inside the weld | Creates hidden voids that reduce strength and may cause brittle fractures |

| Cracks / Porosity | Visible cracks, holes, or bubbles in the weld | Weakens the weld and allows cracks to spread quickly during use |

| Undercutting | Groove along the weld toe at the base metal | Reduces cross-sectional strength and creates natural starting points for cracks |

| Excess Spatter / Contamination | Metal droplets or residue around the weld line | Indicates poor control or dirty base metal; reduces weld quality and appearance |

Factors That Contribute to Bad Welding

Bad welds don’t happen by accident. They usually come from mistakes in preparation, settings, or technique.

- Process errors: Incorrect application of MIG welding, stick welding, or TIG welding leads to weak bonds.

- Filler material problems: Using the wrong filler metal or mishandling wire electrode results in poor adhesion.

- Travel speed and wire feed speed: If travel speed is too fast, penetration suffers. Too slow, and you risk excess buildup or uneven bead.

- Improper welding gun control: Poor angles, inconsistent arc length, or bad shielding gas coverage cause contamination and weak welds.

- Base metal contamination: Dirt, rust, oil, or paint on the base metal prevents proper fusion.

The common thread is lack of control. Skilled welders know how to balance all these factors for consistent, high-quality welds.

Comparing Different Welding Methods

Each welding process has its strengths, but each can also produce defects if applied incorrectly.

MIG Welding (Metal Inert Gas)

- Common in shops working with carbon steel and mild steel.

- Bad MIG welds often show spatter, lack of fusion, or porosity caused by poor shielding gas coverage.

- Correctly done, a MIG weld creates a smooth, uniform weld bead with proper penetration.

Stick Welding (Shielded Metal Arc)

- Known for versatility but prone to slag inclusion or arc blow when mishandled.

- A poor stick weld may look rough and uneven with trapped filler material.

- Proper control results in a durable weld with a uniform appearance.

TIG Welding (Tungsten Inert Gas)

- Preferred for stainless steel and exotic alloys.

- Produces high-quality welds but requires skill to avoid contamination.

- A bad TIG weld shows discoloration, porosity, or weak penetration.

Different metals also affect outcomes. Stainless steel requires precision to avoid warping. Copper alloys demand careful control to prevent cracking. Mild steel is more forgiving but still vulnerable to poor technique.

What materials are hardest to weld without defects?

Stainless steel and copper alloys are more challenging to weld because they require precise technique and control. Stainless steel is prone to warping and distortion if heat is not managed properly. Copper alloys conduct heat quickly, making it difficult to maintain adequate penetration without creating cracks or weak spots. Both demand experienced welders and careful process control to achieve a high-quality weld.

Best Practices to Avoid Bad Welds

Bad welding is preventable with the right preparation, technique, and standards.

- Clean the base metal: Remove oil, rust, and dirt before welding.

- Choose the right filler material: Match the filler metal to the base metal for proper fusion.

- Set correct travel speed and wire feed speed: Balance penetration and bead consistency.

- Maintain welding gun control: Keep angles, arc length, and shielding gas consistent.

- Confirm penetration: Adequate penetration ensures the weld holds under stress.

- Training and certification: AWS certification guarantees welders understand best practices.

- Use robotic welding for high-volume work: Robots maintain consistency over long runs, reducing human error.

| Trait | Good Weld | Bad Weld |

|---|---|---|

| Appearance | Smooth, uniform bead with consistent width and ripple pattern | Sloppy, uneven surface; inconsistent bead thickness |

| Penetration | Adequate penetration into base metal; strong bond throughout | Insufficient penetration; bead sits on surface without fusing deeply |

| Surface Quality | Clean finish; no cracks, porosity, or excess spatter | Cracks, bubbles, slag inclusion, or excessive spatter |

| Strength | Distributes stress evenly; durable under load | Weak points cause stress concentration; prone to failure |

| Edge Condition | Neat edges without melting away base metal | Undercutting at weld toe; grooves weaken joint |

| Overall Reliability | Professional, high-quality weld that holds up across applications | Poor weld that risks failure, rework, or costly repairs |

Spotting the Difference

A good weld creates strength and confidence. A bad weld leads to weakness, failure, and costly rework. By learning the signs of a poor weld, you can avoid risks and make sure your project is built on dependable metalwork.

At EZG Manufacturing, welding is one of our strengths. Our AWS-certified welders and robotic welding systems produce dependable welds across industries, from carbon steel structural assemblies to stainless steel components in specialized machinery.

How EZG Manufacturing Delivers High-Quality Welds

Welding is part of our full contract manufacturing service. We bring years of expertise, advanced equipment, and AWS-certified welders to every project.

- Skilled Welders: Our team handles MIG welding, TIG welding, and stick welding with precision.

- Robotic Welding Technology: FANUC robotic cells complete repetitive welds with accuracy and speed.

- Material Flexibility: We work with carbon steel, stainless steel, aluminum, and copper alloys for projects of any size.

- Integrated Manufacturing: Welding is paired with cutting, bending, machining, and finishing to deliver complete assemblies.

Because we control every stage, we maintain consistency across high-volume production while still meeting custom fabrication requirements. Customers trust us because every weld meets strict quality expectations.

If you’re looking for a contract manufacturing partner you can trust, contact EZG Manufacturing and let’s talk about your next project.