Dust is one of the most common challenges on a construction site. From cutting concrete to demolition activities, construction work often generates high dust levels that can harm both workers and the surrounding environment. What might look like a simple inconvenience is actually a serious safety and health issue that every contractor should address.

Dust isn’t just about sweeping up at the end of the day. It affects air quality, increases health risks, and can even slow down a construction project. Below, we’ll explain the best ways to control dust and show how EZG Manufacturing’s Dust Control equipment gives contractors a dependable solution.

The Problem with Dust on Construction Sites

What Creates Dust?

Construction dust is generated by a wide range of construction activities, especially when working with different materials. Common sources include:

- Demolition activities – knocking down walls, removing flooring, breaking concrete.

- Cutting and grinding – saws, grinders, and drills release fine airborne particles.

- Concrete and masonry work – silica dust from block and brick cutting.

- Unpaved roads and hauling – vehicles stir up dust emissions on dry soil.

- Wood dust – sanding, sawing, and carpentry tasks add airborne particles.

- Earthmoving and excavation – digging, grading, or moving soil exposes dust particles.

- Dry sweeping – sweeping floors or work areas can lift dust particles back into the air.

- Sandblasting – blasting surfaces creates high airborne dust levels.

- Plastering and drywall finishing – sanding drywall compounds or cutting gypsum board.

- Roofing work – cutting asphalt shingles, insulation, or concrete roofing tiles.

- Material handling – loading, unloading, or mixing cement, lime, or other fine powders.

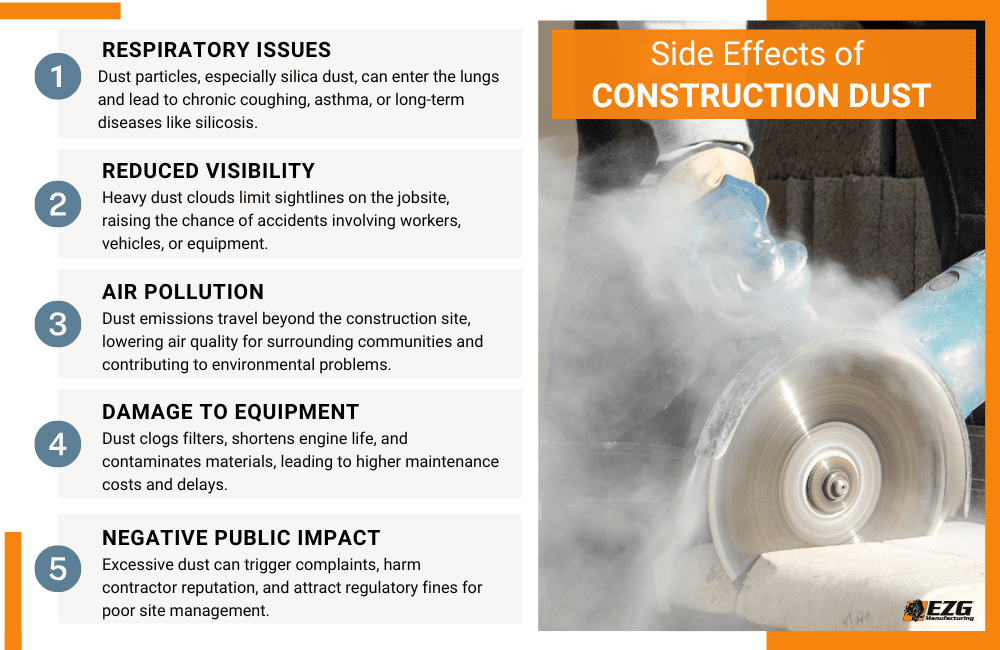

Side Effects of Dust

Construction site dust affects far more than the immediate work area. When dust levels rise, it creates ripple effects across worker health, jobsite safety, and even the community around the project.

- Reduced air quality on and offsite – Dust emissions don’t stay contained to a single work area. Fine dust particles can drift across property lines, lowering air quality for nearby businesses, schools, and homes. For neighbors, this can feel like constant exposure to air pollution from a construction project.

- Increased risk of accidents – High dust levels reduce visibility for equipment operators, drivers, and construction workers on foot. A cloud of dust can make it difficult to see hazards, creating unsafe conditions that can lead to slips, trips, falls, or vehicle collisions.

- Damage to equipment and materials – Dust doesn’t just harm people. It can clog air filters, shorten the life of construction equipment, and damage sensitive tools. Dust settling on freshly applied coatings, finishes, or adhesives can also ruin quality workmanship.

- Environmental impact – Airborne dust particles spread beyond the construction project itself, contributing to erosion, sedimentation, and contamination of nearby water sources. Fine dust settling on plants and soil can damage local ecosystems.

Health Concerns for Construction Workers

Dust is a serious occupational safety issue, and prolonged exposure can lead to dangerous health conditions. For construction workers, dust exposure is more than discomfort. It’s a long-term health concern that can affect their career and quality of life.

| Type of Dust | Health Risks | Common Sources |

|---|---|---|

| Silica Dust | Lung cancer, silicosis, chronic bronchitis | Cutting concrete, stone, brick |

| Wood Dust | Asthma, skin irritation, nasal cancer | Sawing, sanding, carpentry |

| Airborne Dust (general) | Eye irritation, coughing, reduced lung function | Demolition, earthmoving, sweeping |

Dust Control Measures Every Contractor Should Know

Engineering and Worksite Controls

The most effective way to control dust is at the source. Contractors can apply dust suppression and dust containment methods, such as:

Water Application

One of the most common dust suppression methods is applying water directly to dusty surfaces. Spraying or misting helps bind dust particles, preventing them from becoming airborne. This is especially effective for demolition activities, excavation, and soil handling. Continuous mist systems can be set up around high-traffic areas to keep dust levels under control throughout the workday.

Dust Suppression with Calcium Chloride

For unpaved roads or haul routes, calcium chloride is an effective dust suppressant. It absorbs moisture from the air and soil, helping to keep surfaces damp for longer periods than water alone. This prevents dust emissions from vehicles and equipment traveling over dry ground, reducing high dust levels in and around the jobsite.

Vacuum Cleaner Attachments

Tools such as grinders, saws, and drills can be fitted with shrouds connected to vacuums. These attachments capture dust particles at the source, before they have a chance to spread into the air. Using HEPA-filtered vacuums keeps the collected dust contained, protecting both workers and air quality inside the work area.

Plastic Sheeting or Physical Barriers

Dust containment often requires separating the work zone from the surrounding environment. Plastic sheeting can be hung to form temporary walls, while rigid physical barriers help prevent airborne dust from escaping. This method is especially important for indoor construction projects or jobsites near occupied areas where dust exposure must be minimized.

Wind Erosion Protection

Outdoor construction projects often face the challenge of wind carrying dust far beyond the site. Installing fences, netting, or windbreaks reduces dust movement and keeps airborne particles closer to the ground. Covering soil piles and stockpiled materials also limits erosion from wind and helps maintain better control over dust emissions.

Administrative & Work Practice Controls

Simple adjustments to construction work can reduce dust exposure:

- Rotate construction workers in high dust level areas.

- Schedule high-dust construction activities during low-traffic hours.

- Train crews to use proper dust control measures consistently.

Personal Protective Equipment (PPE)

Even with control measures, some dust will remain. Contractors should provide PPE such as:

- Respiratory protection (N95 or higher).

- Eye protection to prevent irritation from dust particles.

- Protective clothing when working with different materials like wood or cement.

Dust Control Equipment that Works in the Field

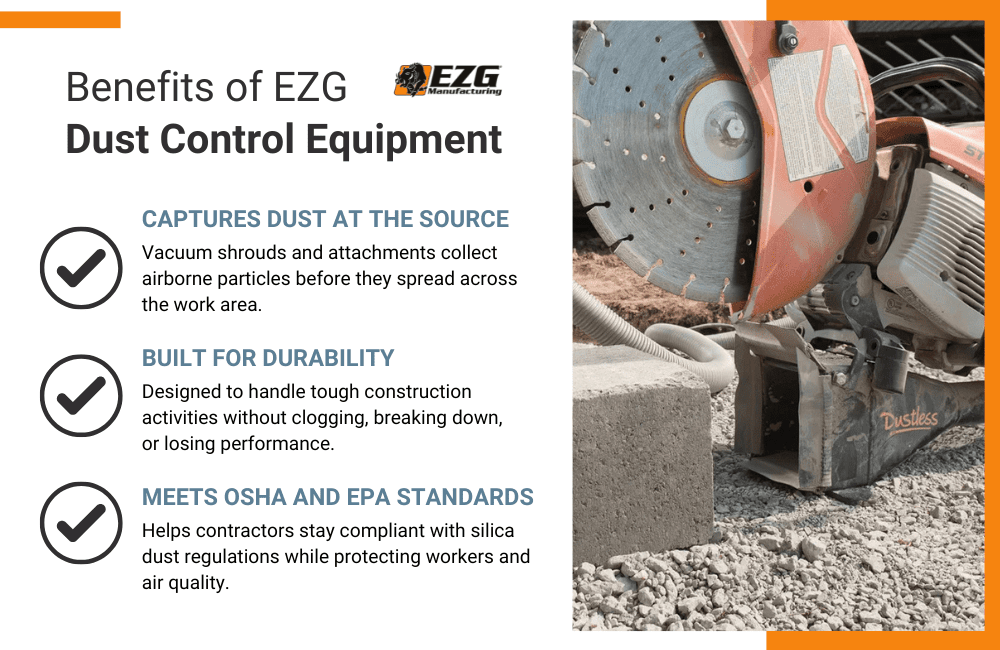

EZG Dust Control Solutions

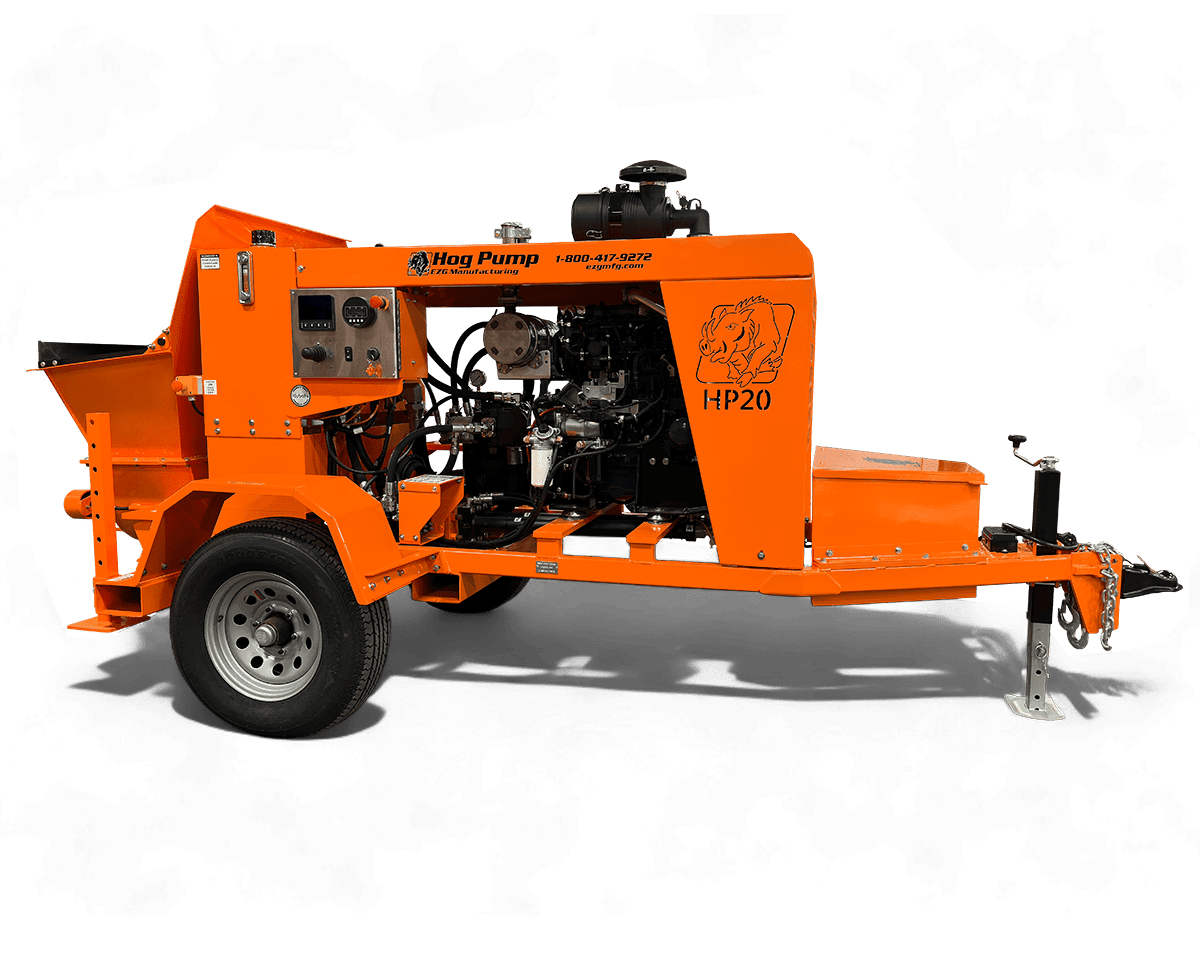

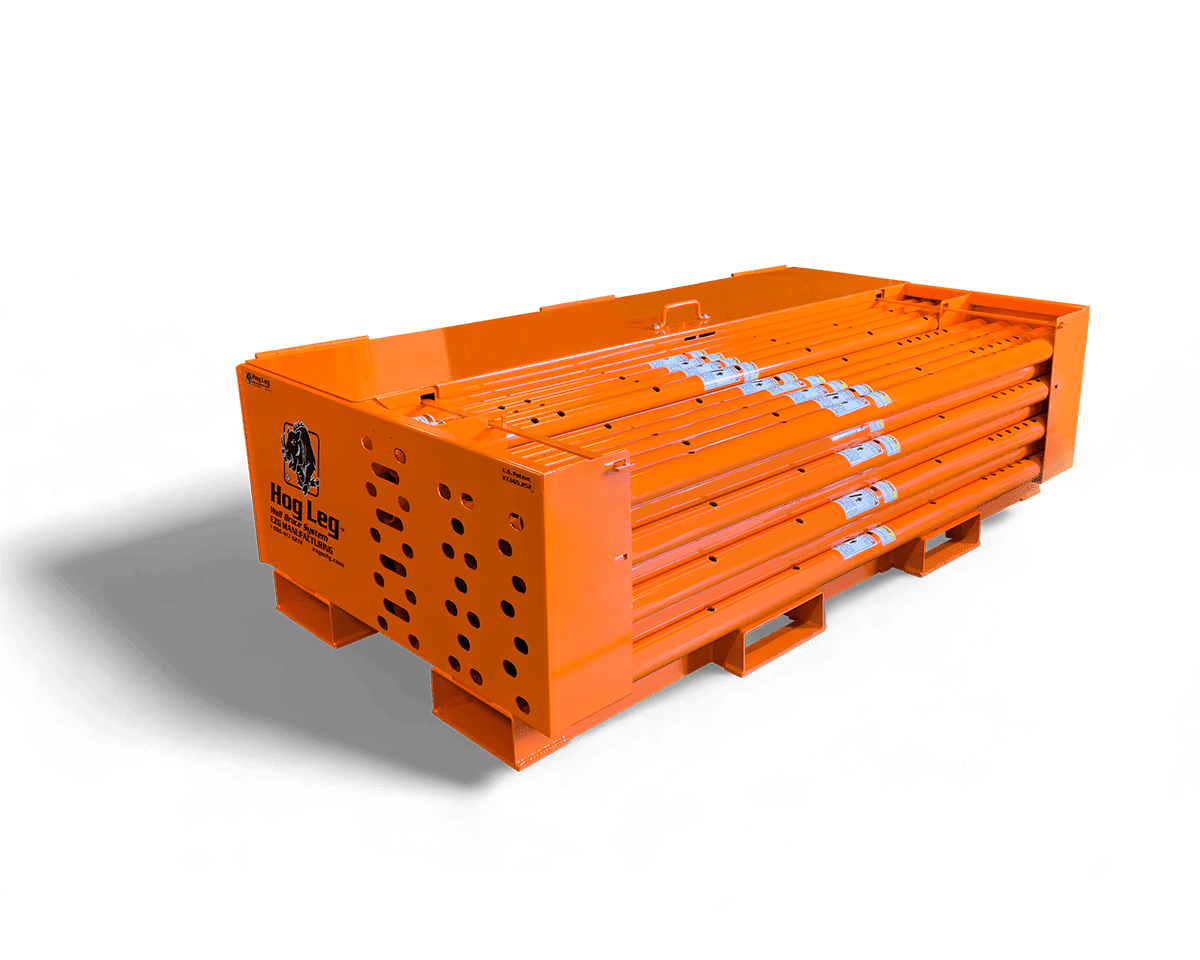

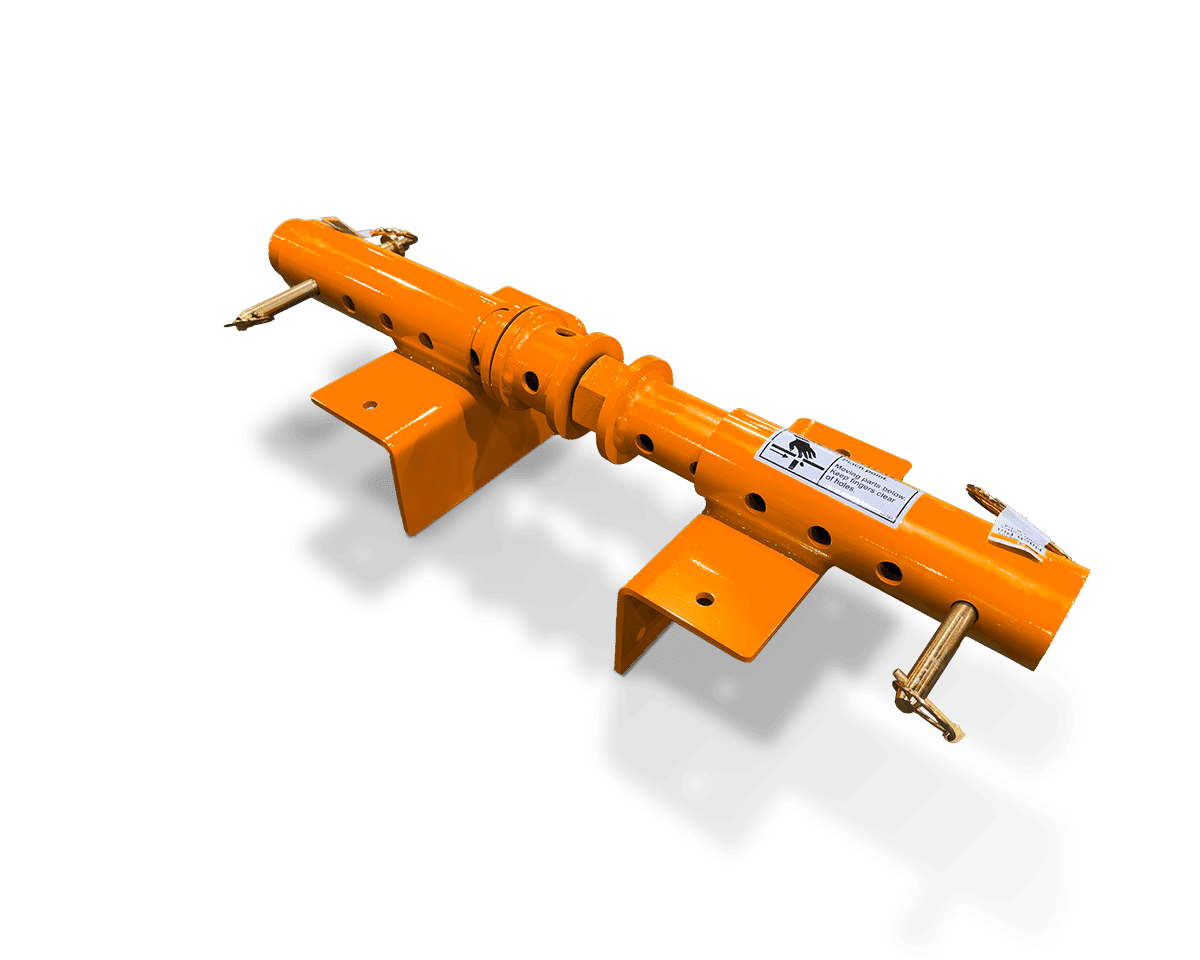

EZG Manufacturing offers reliable dust suppression systems through Dustless Technologies, built with the same durability and problem-solving mindset as all EZG equipment. Contractors can choose from:

- HEPA vacuums and wet+dry vacuums – for after-work cleanup of dust containment areas.

- Dust Buddies, Cut Buddie, and Dust Bull – vacuum shrouds that capture airborne dust directly at the tool.

These systems are designed to meet OSHA and EPA standards, keeping construction projects compliant while protecting construction workers.

Key Benefits of EZG Dust Control Equipment

- Will not blow dust back into the air.

- DustBulls fit most gas-powered cut-off saws.

- Vacuum shrouds work with saws and grinders for point-of-origin dust containment.

- Long-lasting durability built for the demands of the construction industry.

Practical Dust Control Tips for Contractors

- Use wet cutting methods instead of dry cutting to limit airborne particles.

- Cover debris piles with plastic sheeting or tarps.

- Apply calcium chloride or water spray to unpaved roads on dusty construction projects.

- Regularly check and maintain dust suppression systems.

- Use HEPA vacuums for thorough cleanup after demolition projects.

By applying these methods, contractors can reduce dust levels, improve air quality, and maintain safer construction sites.

Regulatory Guidelines and Compliance

Dust control is required to meet legal guidelines. OSHA silica dust standards require contractors to limit exposure during common construction tasks such as cutting, drilling, and grinding. At the same time, the EPA regulates dust emissions and air pollution tied to demolition projects and unpaved road work. On larger construction projects, contractors are also expected to document their dust control measures to demonstrate compliance during inspections. These regulations are designed to reduce long-term health risks, protect construction workers, and safeguard the surrounding community from airborne dust.

Choosing the Right Dust Control Method for Your Jobsite

The right dust suppression system depends on the type of work being performed. By matching the method to the construction project, contractors can maintain safer work areas and avoid downtime from high dust levels.

| Construction Activity | Best Dust Control Method |

|---|---|

| Cutting Concrete | Dust Bull + wet cutting |

| Demolition Projects | Water mist + HEPA vacuum |

| Unpaved Road Work | Calcium chloride + water truck |

| Wood Cutting | Vacuum shrouds + HEPA vacuums |

| Small Indoor Work Area | Plastic sheeting + portable vacuum cleaner |

Protect Your Crew and Your Bottom Line

Dust may seem like a small problem, but for the construction industry it carries big consequences, like health concerns, safety risks, and compliance issues. Contractors who invest in the right dust suppression systems not only protect their workers but also maintain more productive jobsites.

At EZG Manufacturing, we understand the challenges of controlling dust because we’ve been in the field ourselves. That’s why we build durable, long-lasting equipment designed to solve real problems for contractors. EZG Dust Control equipment gives you dependable solutions that protect your crew and keep your project moving forward.

Contact EZG today to learn more about our Dustless Technologies product line and how it can help you control dust on your next construction site.