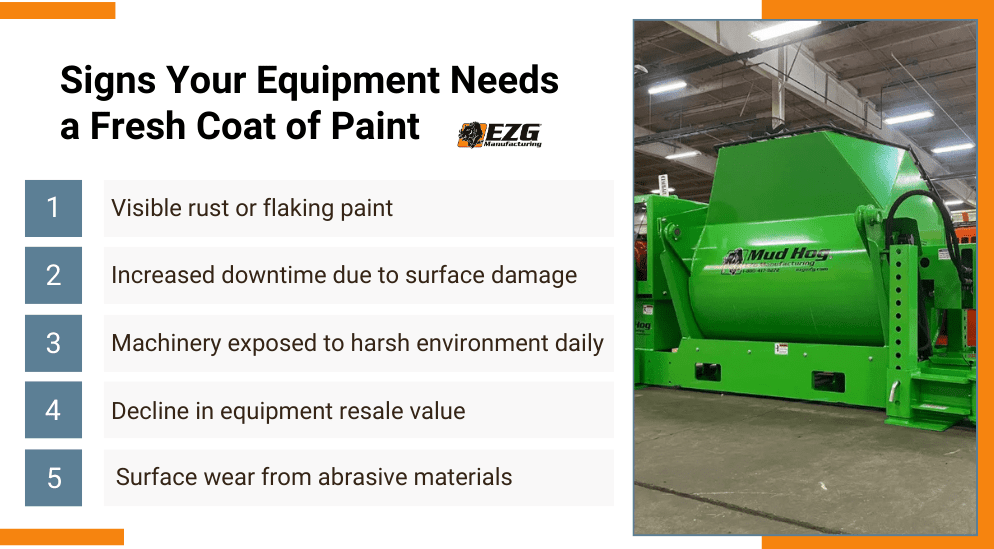

After years on tough job sites, heavy equipment takes a beating. Exposure to abrasive materials, constant weather changes, and demanding use wears away at surfaces. A fresh coat of industrial paint is more than just about appearance. It’s about long-term durability, lower maintenance costs, and keeping your machinery ready for hard work. Contractors who invest in protective coatings not only save money over the life of their equipment, but also maintain reliable performance.

What is Industrial Equipment Painting?

Industrial equipment painting is the process of applying specialized coatings to machinery and heavy-duty equipment to protect against wear, corrosion, and environmental damage. Unlike standard paint jobs, it uses durable industrial coatings such as powder coat, epoxy, or polyester resin-based paints that are engineered to withstand extreme conditions.

Why Heavy Industrial Equipment Painting Matters

Every contractor knows equipment is a major investment. Painting isn’t just about looks; it’s about protection. Proper coatings:

- Create a protective layer that shields against moisture, chemicals, and abrasive materials.

- Improves durability in demanding environments like masonry, fencing, and refractory job sites.

- Helps new equipment stay in top condition and gives older equipment a second life with a professional finish.

- Support resale value with a professional appearance

By applying the right coating, contractors keep their equipment reliable, safe, and ready for high-volume use.

Common Environmental Challenges for Equipment

Industrial machinery faces constant punishment from the job site. Without protective coatings, exposure leads to surface damage, corrosion, and expensive repairs. Contractors deal with several recurring challenges, including:

- Extreme weather: Rain, snow, heat, and humidity speed up corrosion and cause paint to fade.

- Abrasive materials: Sand, gravel, lime, and other job site materials grind against equipment surfaces.

- Chemical exposure: Harsh cleaners, cement, or refractory materials break down unprotected coatings.

- UV rays: Prolonged sunlight causes paint to fade and surfaces to become brittle.

- Moisture and condensation: Trapped water accelerates rust, especially on steel components.

- High-volume usage: Daily wear and tear quickly strips away weak coatings.

These factors directly affect performance, reliability, and long-term costs. A durable protective coating helps resist damage and extends the useful life of equipment.

| Environmental Factor | Impact on Equipment | Benefit of Protective Coating |

|---|---|---|

| Extreme Weather | Corrosion, fading | Long-lasting protection |

| Abrasive Materials | Surface wear | Durable coatings |

| Chemicals | Surface damage | Corrosion resistance |

| UV Exposure | Fading, brittleness | Maintains finish & durability |

The Risks of Neglecting Paint & Coatings

Letting paint deteriorate comes with consequences. Old paint exposes steel and components to rust. Over time, this shortens the life of equipment, increases downtime, and drives up costs. Contractors also risk lower resale values when machinery looks neglected. Industry testing benchmarks such as ASTM standards for corrosion resistance, abrasion resistance, and ISO salt-spray testing highlight how quickly untreated steel can degrade under harsh conditions. EZG’s industrial coatings are applied and tested in alignment with these recognized standards, providing contractors with confidence that their equipment will stand up to the environments they face every day.

Benefits of Durable Industrial Coatings

Modern coatings deliver long-lasting protection. For heavy-duty equipment, powder coat and other advanced coatings provide:

- Strong defense against corrosion

- Resistance to extreme weather and abrasive conditions

- Fewer repaint cycles compared to wet paint

- Clean appearance that represents professionalism on job sites

The Industrial Painting Process

High-performance coatings are the result of a carefully managed process that combines preparation, material selection, and professional application. Each step directly impacts how long the coating will last and how well it will protect your equipment.

1. Surface Cleaning and Prep

The first step is creating a clean, smooth base for paint or powder coat. Dirt, grease, and job site residue prevent coatings from bonding properly. Contractors or manufacturers typically use degreasers, pressure washing, or media blasting to remove buildup

2. Removal of Old Paint and Corrosion

If equipment has existing paint or visible rust, it must be removed before a new coat is applied. Old, flaking paint leaves weak spots that expose steel to moisture. Corrosion also spreads quickly if left untreated. Sandblasting, grinding, or chemical stripping are common methods used to remove damaged paint and rust.

3. Selection of Proper Industrial Coating

Not every coating is right for every environment. Heavy industrial equipment often requires powder coat finishes for superior durability, but polyester resin-based coatings or epoxy paints may be used depending on exposure to chemicals, UV rays, or extreme temperatures. The right choice depends on the work environment and the materials the equipment will face daily.

4. Application and Curing

Once the equipment is prepped and the coating selected, the application process begins. For powder coating, electrostatic charges are used to bond the dry powder particles to the metal surface. With wet paint, precision spray guns deliver an even coat. After application, the coating is cured using controlled heat, which hardens it into a tough, protective layer.

5. Final Inspection for Quality and Consistency

The process doesn’t stop once the coating is applied. Every piece of equipment should undergo inspection to check for coverage, thickness, and overall finish quality. This step guarantees the protective layer is consistent across the entire machine, eliminating thin spots that could expose steel to rust.

Powder Coat vs. Wet Paint for Industrial Equipment

| Coating Type | Durability | Corrosion Resistance | Appearance | Longevity |

|---|---|---|---|---|

| Wet Paint | Moderate | Fair | Smooth | Shorter |

| Powder Coat | High | Excellent | Consistent | Longer |

Powder coating is often the preferred choice because it provides a thicker, more durable layer. It resists chipping, fading, and corrosion far better than traditional wet paint.

Maintenance & Care Tips After Painting

Applying the coating is only part of the process. Regular care extends its life:

- Wash machinery with mild soap and water to remove dirt and abrasive material.

- Schedule inspections every few months to catch chips or worn spots early.

- Touch up exposed areas promptly before corrosion begins.

- Avoid harsh solvents or pressure washers that can damage coatings.

How Painting Protects Against Long-Term Costs

Heavy industrial equipment is one of the largest investments a contractor will make. Beyond the purchase price, most of the expense comes during the life of the machine. Every repair, every hour of downtime, and every early replacement adds up. Applying and maintaining protective coatings directly reduces those long-term costs, making painting a smart financial decision in addition to a practical one.

Lower Repair Bills Over Time

Uncoated or poorly coated machinery is more prone to rust, pitting, and surface damage. Once corrosion sets in, repairs often require grinding, welding, or even replacing structural components. Those repairs can quickly exceed the cost of a proper paint job. By keeping surfaces protected from moisture, chemicals, and abrasive materials, industrial coatings reduce the likelihood of these expensive fixes. A single repainting cycle is far more affordable than frequent major repairs.

Less Downtime from Equipment Failures

Downtime is one of the most expensive problems on a construction site. When a machine is out of service due to preventable surface damage, it stalls production, impacts schedules, and increases labor costs. Protective coatings extend the lifespan of equipment parts that frequently fail under harsh conditions — such as hoppers, mixers, and frames. By minimizing breakdowns, contractors keep their crews productive and avoid the ripple effect of project delays.

Higher Resale Value When Upgrading to New Machinery

Equipment appearance matters at resale. Buyers and auction houses look closely at condition, and a machine with a fresh coat of paint signals proper care and reliable use. A neglected surface, on the other hand, suggests hidden issues and leads to lower offers. Contractors who maintain coatings consistently receive higher resale prices, giving them more capital to reinvest in new machinery.

Long-Term ROI: Coated vs. Uncoated Equipment

To put the value into perspective, consider the following comparison:

| Factor | Uncoated Equipment | Coated Equipment |

|---|---|---|

| Average Lifespan | 5–7 years before major repairs | 10+ years with proper coatings |

| Annual Repair Costs | High due to corrosion and wear | Significantly reduced |

| Downtime | Frequent, often unplanned | Lower, more predictable |

| Resale Value | Reduced by 20–30% | Maintained or increased |

Protective coatings clearly pay for themselves by extending equipment life, lowering unexpected expenses, and keeping machines productive. For contractors managing fleets of heavy machinery, these savings multiply across every piece of equipment on the job site.

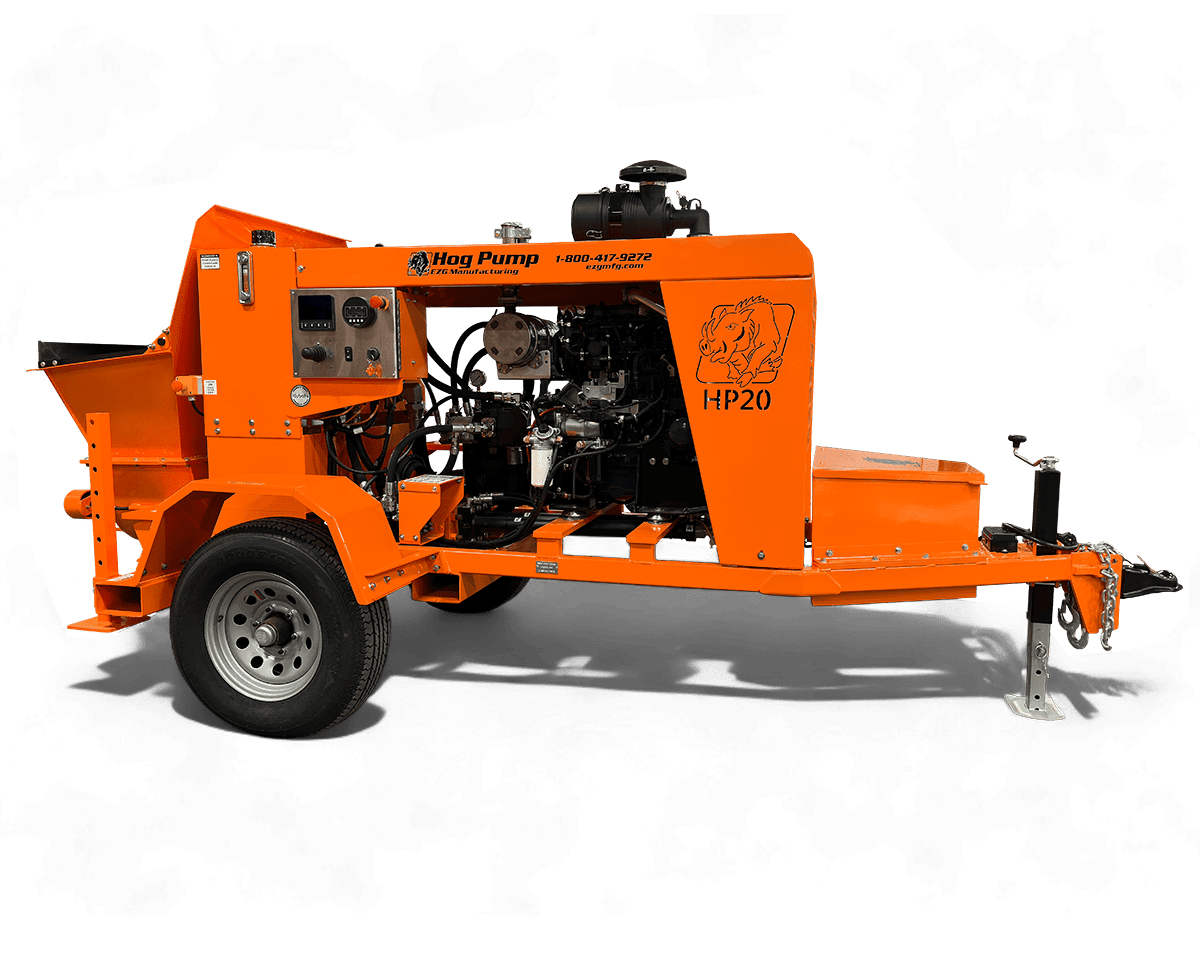

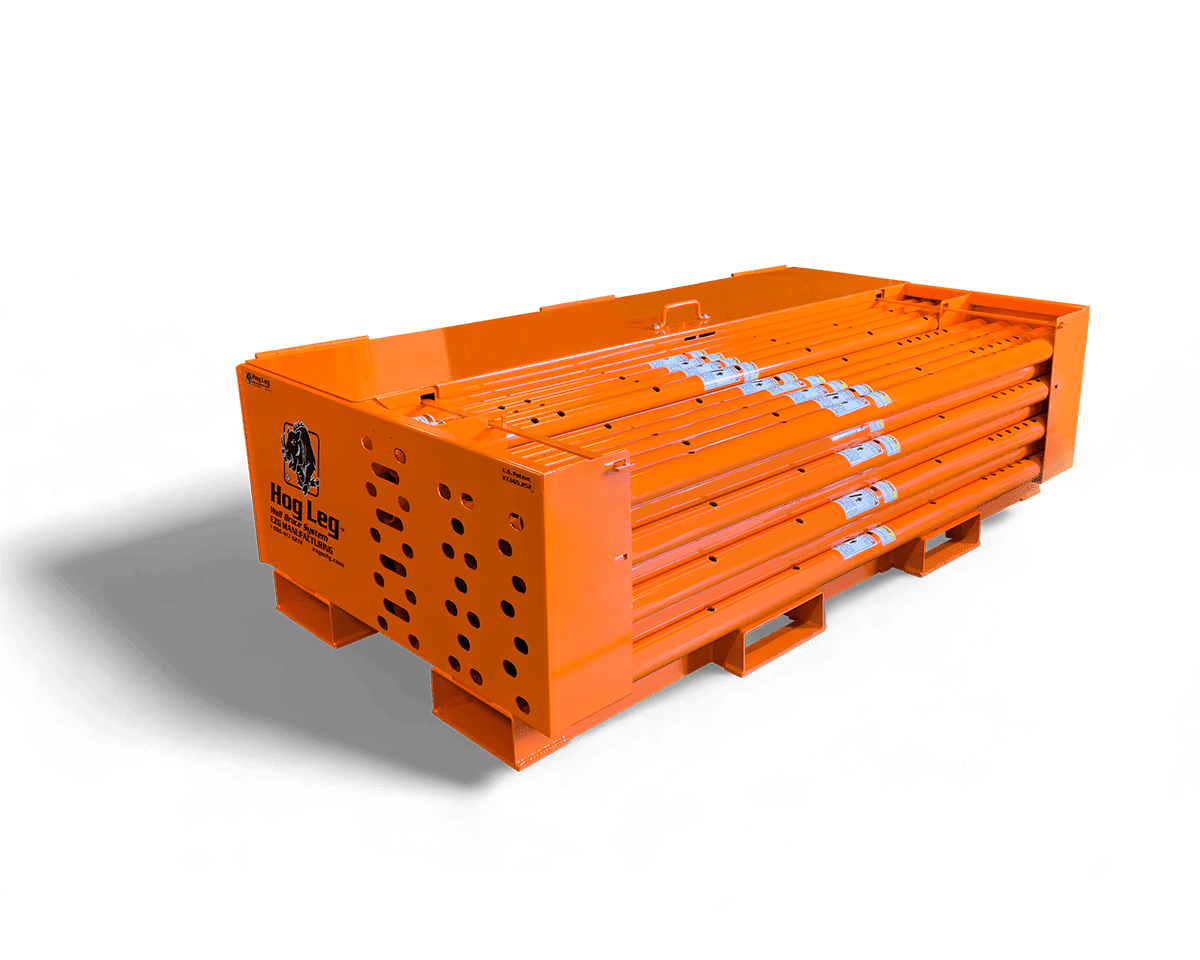

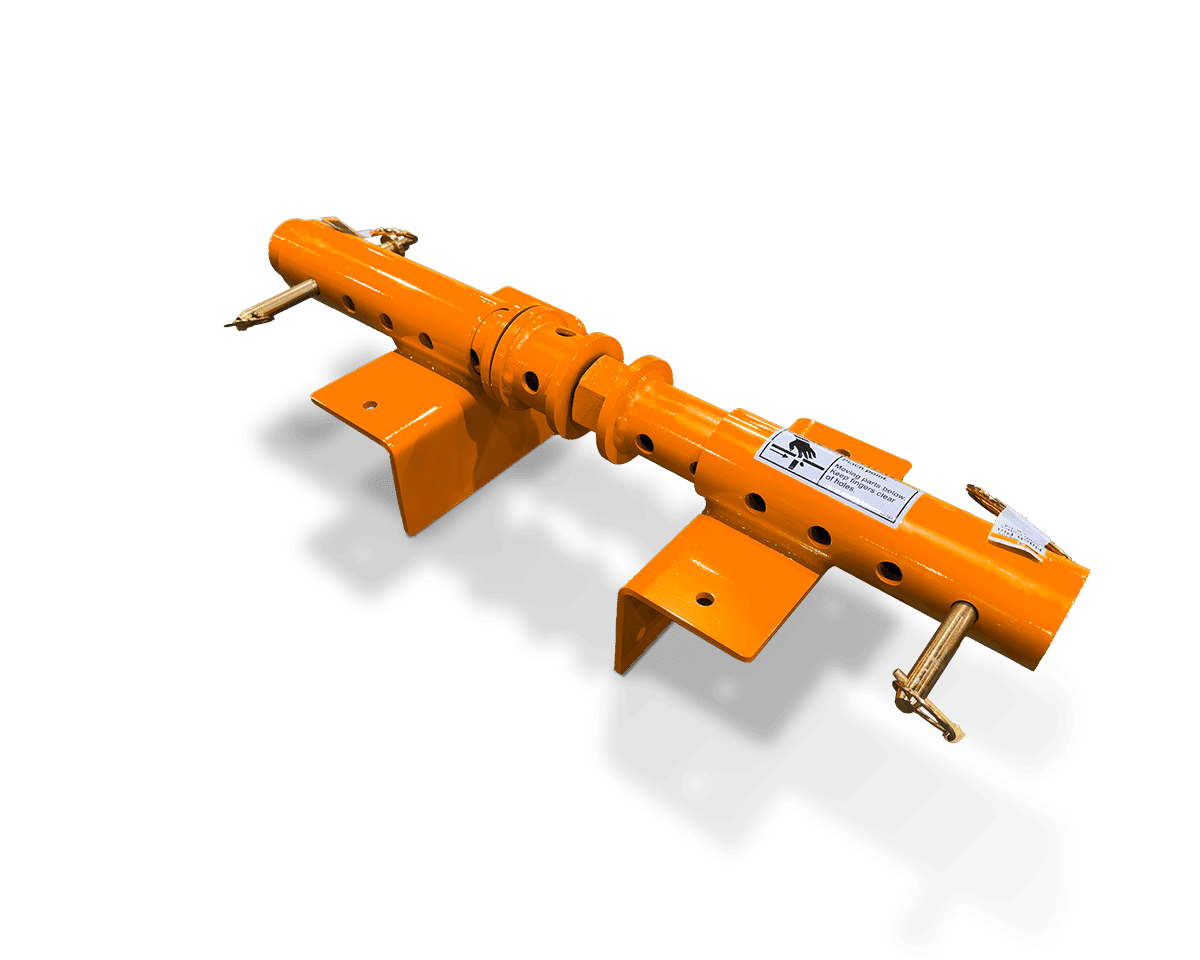

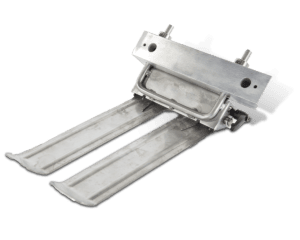

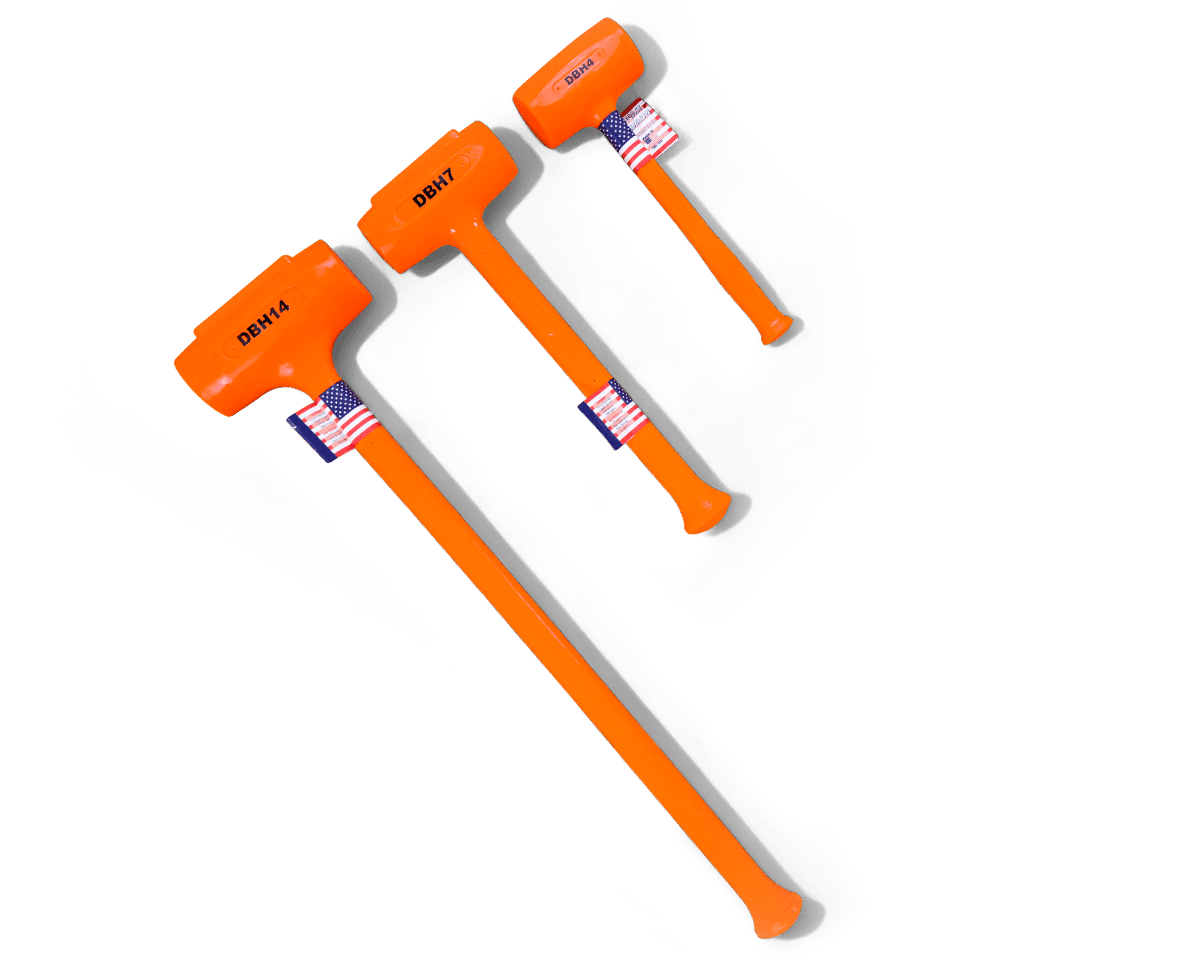

EZG Manufacturing’s Powder Coat Painting Services

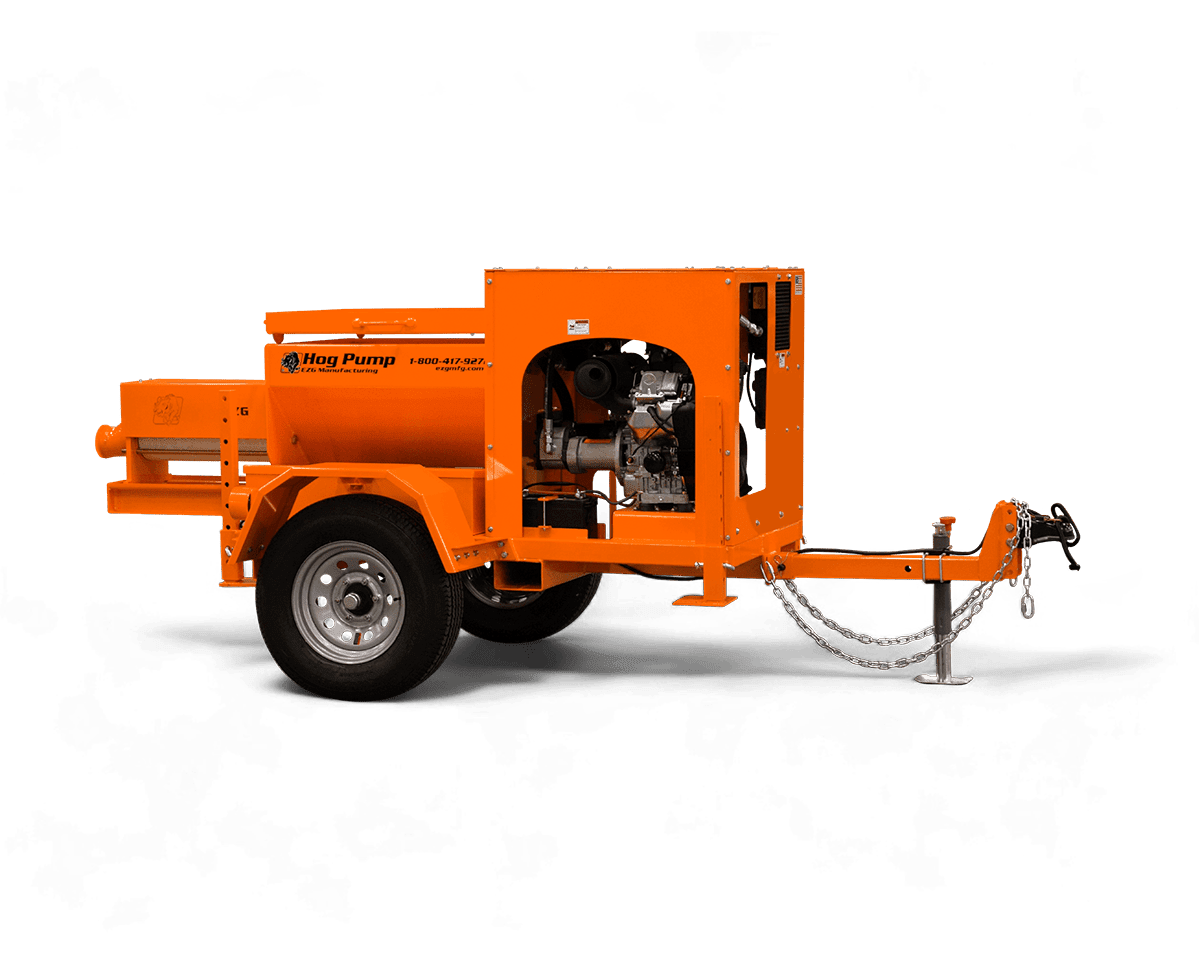

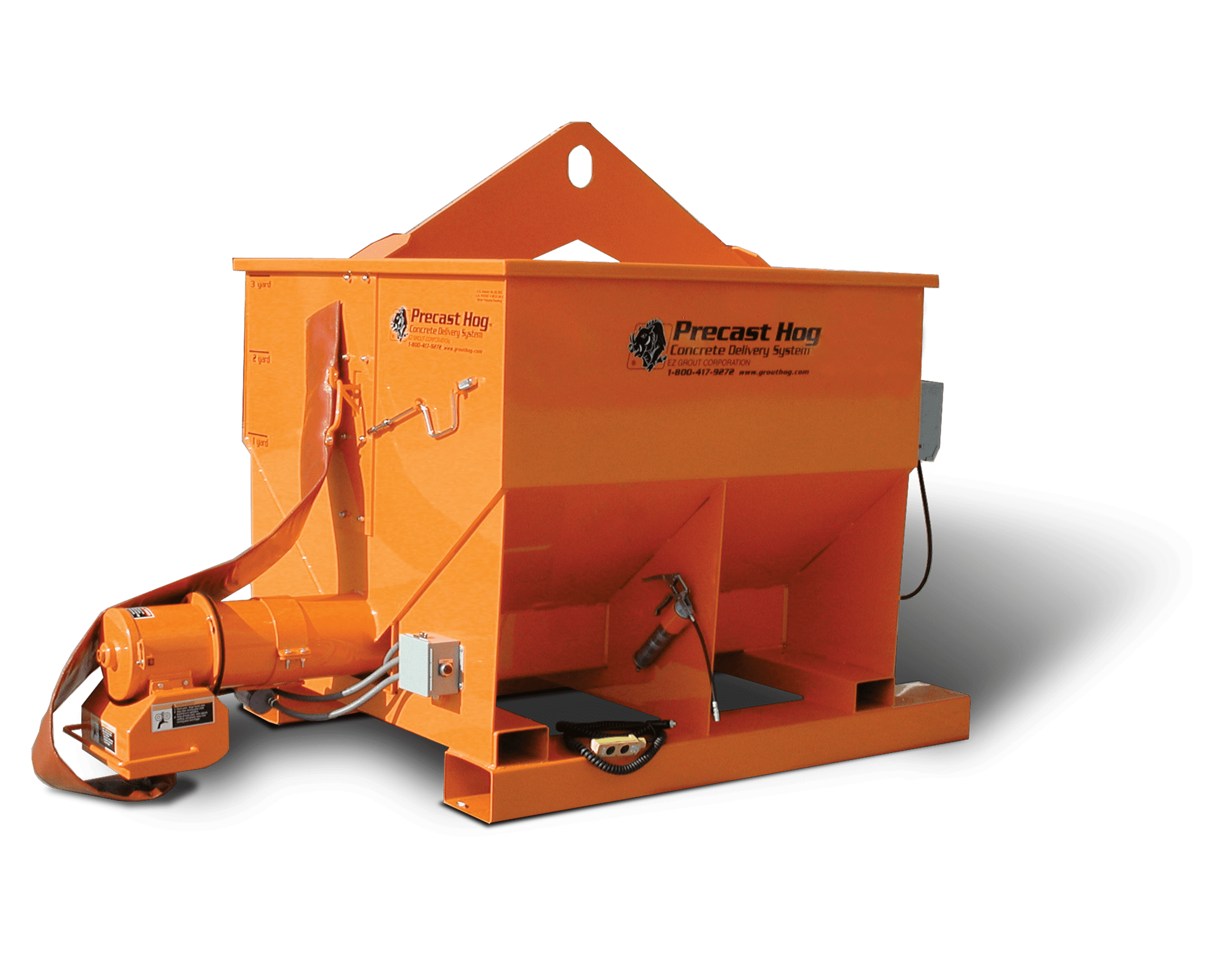

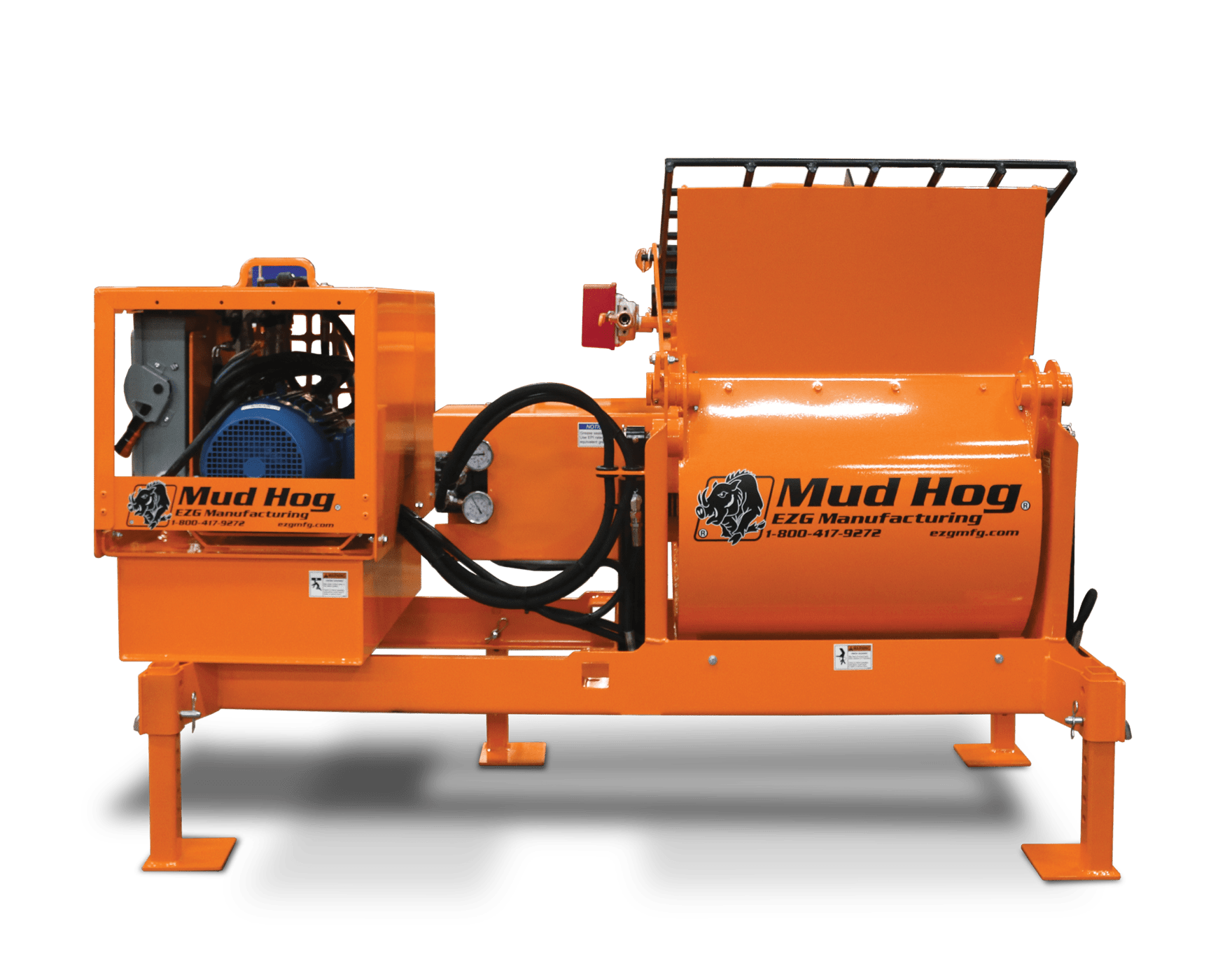

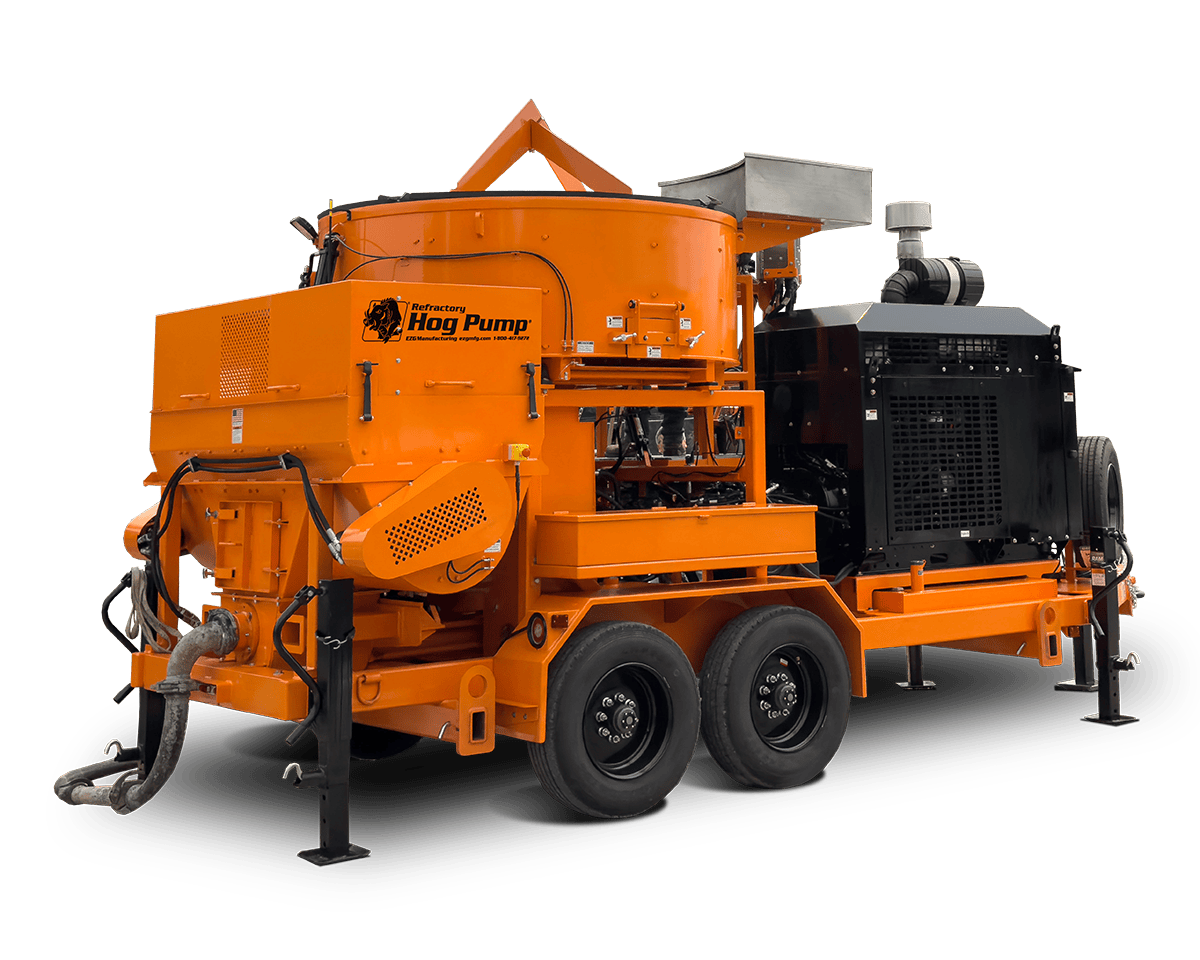

At EZG Manufacturing, our experience comes directly from the field. We understand how masonry mixers, fencing equipment, and refractory machines are used — and abused — on job sites. That’s why we offer in-house powder coat and wet paint services designed for heavy industrial equipment. Our coatings are built to stand up to extreme conditions and give your machinery a professional finish. Contractors rely on us for both durability and appearance, knowing the job will be done right.

Working with a manufacturer who builds equipment for masonry, fencing, and construction markets means you get coatings that match real-world demands. At EZG Manufacturing, customer satisfaction is a guarantee. We listen to contractors, build long-lasting machines, and provide services like powder coating that protect your investment for years to come.

Contact EZG Manufacturing to learn more about our powder coat painting services and how we can help protect your equipment from the harshest conditions.