Many manufacturers face the same challenge: meeting production demand without overextending their own facilities or workforce. When labor costs rise, timelines tighten, and new product introduction cycles accelerate, businesses turn to trusted partners who can take on part or all of the assembly process.

That’s where contract assembly services come in. These services allow companies to outsource their assembly operations to an experienced contract manufacturer capable of managing everything from sub-assemblies to final assembly and inspection.

What Are Contract Assembly Services?

Contract assembly services refer to outsourcing part or all of your product assembly to a specialized manufactuer. Instead of handling assembly in-house, a company partners with a provider that has the tools, trained staff, and production systems needed to assemble products efficiently.

In simple terms, contract assembly means hiring another company to put your products together for you. The contractor may build entire machines, sub-assemblies, or finished goods based on your drawings or specifications. Businesses often use this service when they lack the space, equipment, or labor to handle full-scale production on their own.

These assembly services can cover anything from small-scale hand assembly of electrical components to large mechanical builds like frames, housings, or structural systems. The contract assembly partner provides the space, workforce, and equipment to complete each product to the exact client requirements and quality standards.

By outsourcing assembly, manufacturers can meet project deadlines faster, reduce labor costs, and maintain consistent quality. All without investing in additional facilities or workforce.

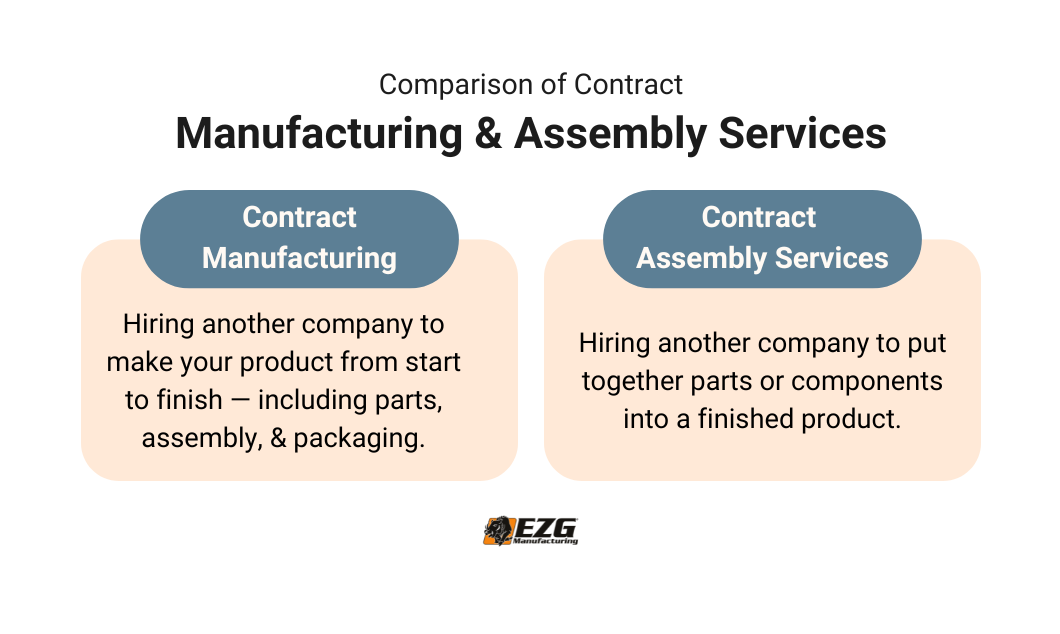

What’s the difference between contract assembly and contract manufacturing?

Contract manufacturing covers the entire production process, from sourcing raw materials and fabricating parts to assembling, testing, and packaging the final product. It’s a full-service approach where the contractor handles every stage of manufacturing on behalf of the client.

Contract assembly, on the other hand, focuses specifically on putting together pre-made components or sub-assemblies into finished or semi-finished products. This might include mechanical assembly, electrical integration, system installation, or final product finishing.

In short, contract manufacturing builds the parts, while contract assembly puts them together.

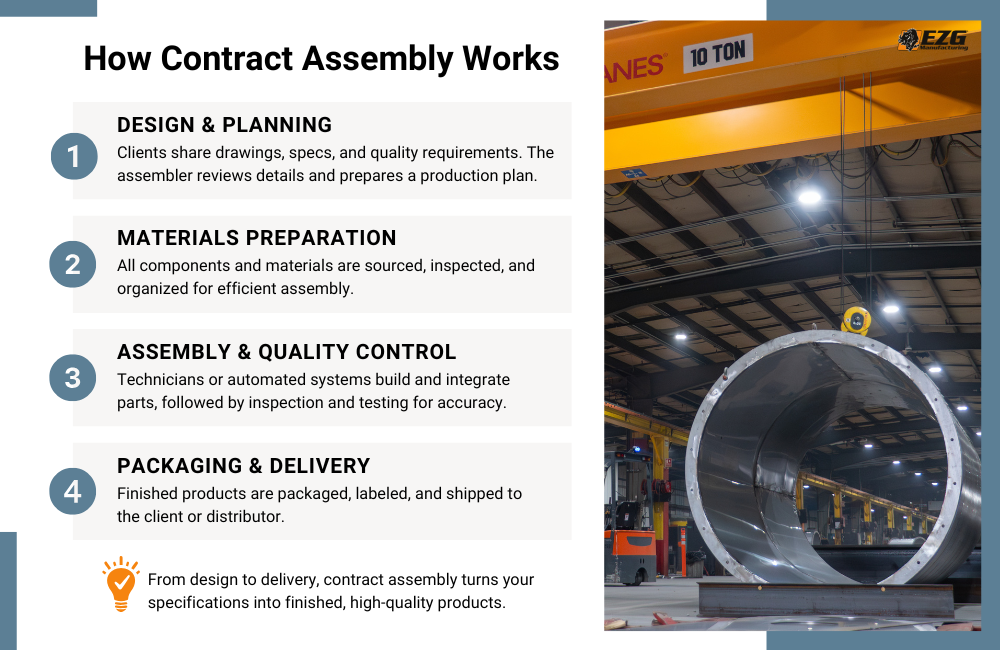

How Contract Assembly Works

Once a company decides to outsource, the assembly process follows a clear and organized path. It involves multiple phases designed to produce a reliable, ready-to-use final product.

Here’s how it typically unfolds:

1. Design & Specifications

The client provides CAD drawings, part numbers, and assembly instructions that outline how the finished product should look and function. The contract assembler reviews every detail, checks for manufacturability, and may recommend design adjustments that improve assembly efficiency or reduce production time. Early collaboration at this stage prevents costly changes later in the manufacturing process.

2. Material Procurement

The contract assembly manufacturer sources all necessary materials, including raw metals, fabricated parts, fasteners, or electronic components. Suppliers are selected based on quality, lead times, and reliability to support consistent production and meet delivery schedules. Maintaining strong supplier relationships helps manage supply chain efficiency and keeps delivery on track.

3. Fabrication & Sub-Assembly

This phase involves machining, welding, bending, and powder coating. Each part is built, finished, or modified to exact dimensions so they fit perfectly during final assembly. Sub-assemblies, such as welded frames or electrical modules, are often tested before moving to the next stage to verify compatibility.

4. Final Assembly

During final assembly, all components come together on the assembly line. Technicians use fixtures, torque tools, and alignment systems to assemble parts with accuracy and repeatability. This stage often includes installing fasteners, bearings, or electrical components, depending on the product type.

5. Functional Testing & Quality Control

Before any assembled product leaves the floor, it undergoes functional testing, visual checks, and final inspection to confirm proper performance. Testing can include fit validation, pressure checks, load testing, or electrical continuity checks. The contract assembly company documents all results to verify compliance with the customer’s quality standards.

6. Packaging & Delivery

Once approved, the product is packaged for safe transport or direct installation. Protective materials, labeling, and custom crates may be used depending on the product’s size and sensitivity. The contract assembler coordinates logistics or works with the client’s supply chain management team to ensure on-time delivery and accurate order tracking.

How does quality control work in contract assembly?

Quality control begins at every stage of the manufacturing operation, from incoming material inspection to the final assembly. A reliable contract assembly company performs dimensional checks, load tests, and visual inspections to confirm compliance with client requirements and industry standards.

Types of Contract Assembly Services

Different industries require different types of assembly work, and an experienced contract assembly provider can tailor services to fit each application. Here are some of the most common types:

- Mechanical Assembly: Building welded frames, steel structures, and precision fixtures. Common in industrial, construction, and heavy-equipment applications.

- Sub-Assembly: Creating modular units or partially assembled systems that integrate into a larger product later in the production process.

- Electrical and Electronic Component Assembly: Integrating wiring harnesses, controls, or sensors for electronics manufacturing or medical device applications.

- Custom Metal Assembly: Producing custom metal enclosures, guards, and frames through cutting, bending, welding, and finishing.

- Packaging & Kitting: Preparing finished goods for shipping or retail-ready distribution.

Can contract assembly handle custom or low-volume projects?

A skilled contract assembler can support both prototype and full-scale production runs. Companies often outsource new product introduction projects to a trusted contract assembly manufacturer to reduce startup risk while still maintaining production flexibility.

What materials are commonly used in contract assembly?

Most assemblies involve steel, stainless steel, aluminum, or powder-coated metals, chosen for their strength, corrosion resistance, and appearance. These materials are frequently used in machinery, medical device, and electronics applications where precision and durability matter.

Benefits of Contract Assembly Services

Choosing the right contract manufacturing partner can have lasting advantages. Here are some of the most important:

- Cost Efficiency: Outsourcing assembly can lower labor costs, eliminate the need for extra workspace, and cut overhead. You pay only for the production capacity you need, keeping budgets predictable.

- Consistent Quality: Experienced contract assemblers use repeatable processes, specialized tools, and strict quality control to deliver consistent results across every production run.

- Faster Turnaround: Established providers can quickly adapt their assembly line to meet fluctuating production demand, minimizing downtime and lead times.

- Flexibility and Scalability: Whether you need 100 units or 10,000, contract assembly allows you to scale production up or down without additional investment in labor or equipment.

- Focused Resources: By outsourcing assembly, your internal teams can focus on product development, design improvements, or supply chain coordination.

- Reduced Risk: Experienced contract manufacturers maintain proper certifications and follow proven procedures to reduce product recalls, rework, or costly returns.

What to Look for in a Contract Assembly Partner

Finding the right contract assembly manufacturer can determine how well your project performs. Here are the most important factors to consider:

- Technical Capabilities: Look for a partner offering fabrication, machining, welding, bending, and finishing services in-house. This creates a smoother manufacturing operation and reduces coordination between vendors.

- Experience and Reliability: Choose a company with a long-standing record in contract assembly and contract manufacturing, supported by case studies or proven client success.

- Facility and Equipment: A large, modern facility allows for multiple assembly lines, quality inspection areas, and efficient supply chain management.

- Quality Control Process: Confirm that your partner documents testing, inspection, and traceability from the first part to the final product.

- Communication and On-Time Delivery: Clear communication, status updates, and consistent on-time delivery are what define a dependable contract assembly company.

EZG Manufacturing’s Approach to Contract Assembly

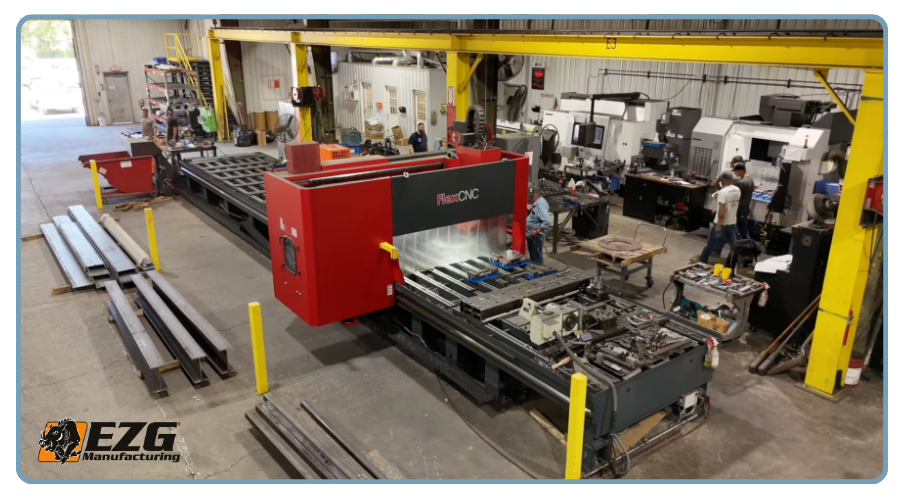

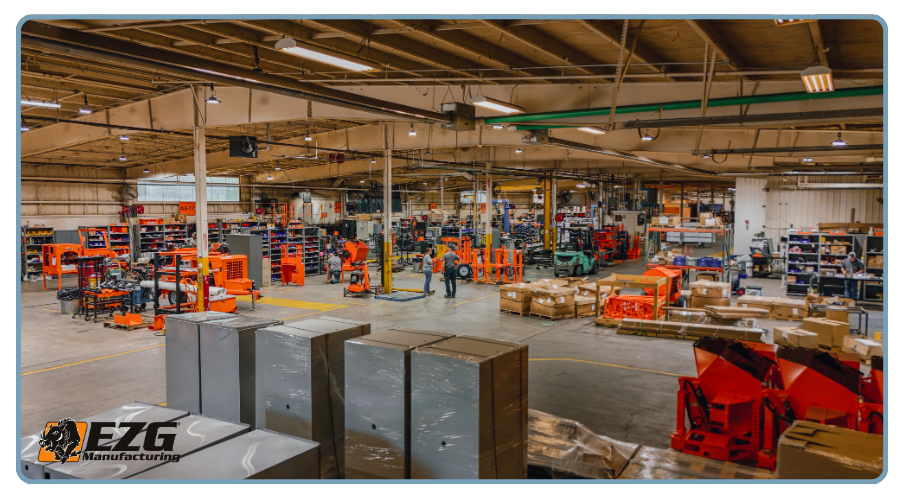

At EZG Manufacturing, we’ve built our reputation on trust, durability, and problem-solving. With over 25 years of experience in contract manufacturing services, we provide reliable assembly operations for industries ranging from construction and industrial equipment to electrical and mechanical systems.

Our 120,000-square-foot facility houses a complete suite of production capabilities:

- Metal Fabrication & Machining: CNC cutting, milling, and drilling for parts that fit perfectly every time.

- Welding: Skilled MIG and TIG welding for heavy-duty and precision assemblies.

- Bending & Forming: Accurate forming processes that meet tight tolerances for each component.

- Powder Coating & Finishing: Durable, corrosion-resistant finishes that extend product lifespan and meet appearance standards.

From system integration and functional testing to final inspection and shipping, our team manages every detail of the assembly process with professionalism and attention to detail.

Every project we take on is supported by decades of hands-on manufacturing experience. From new product introduction to ongoing production support, EZG helps companies focus on growth while we handle the heavy lifting.