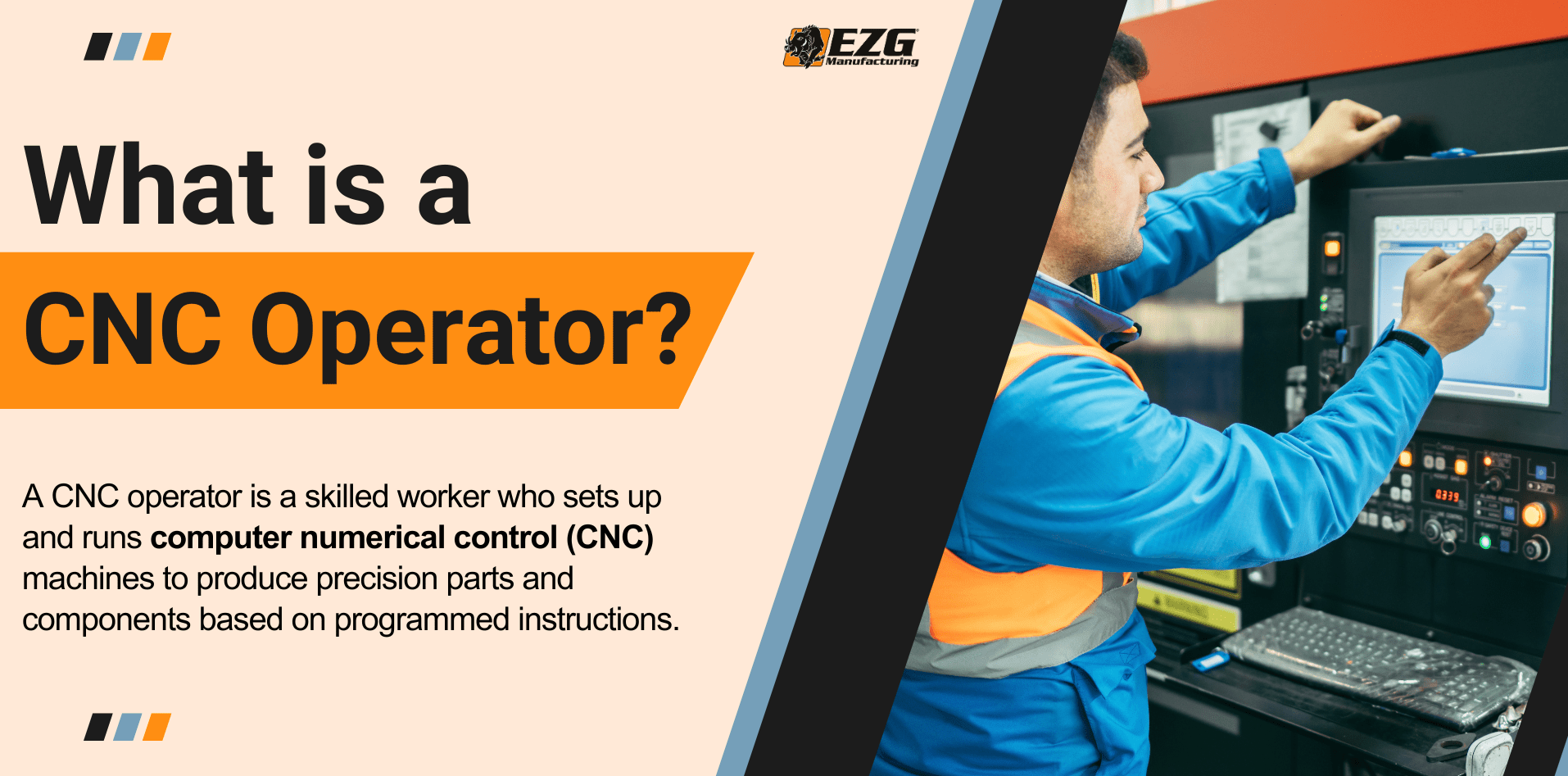

Advanced manufacturing demands precision and repeatability like never before, and CNC operators play a hands-on role in making that happen. These skilled professionals work directly with computer numerical control (CNC) machines to turn digital designs into real-world products. From a one-off prototype to a full production run, they ensure that every cut, contour, and hole meets exact specifications.

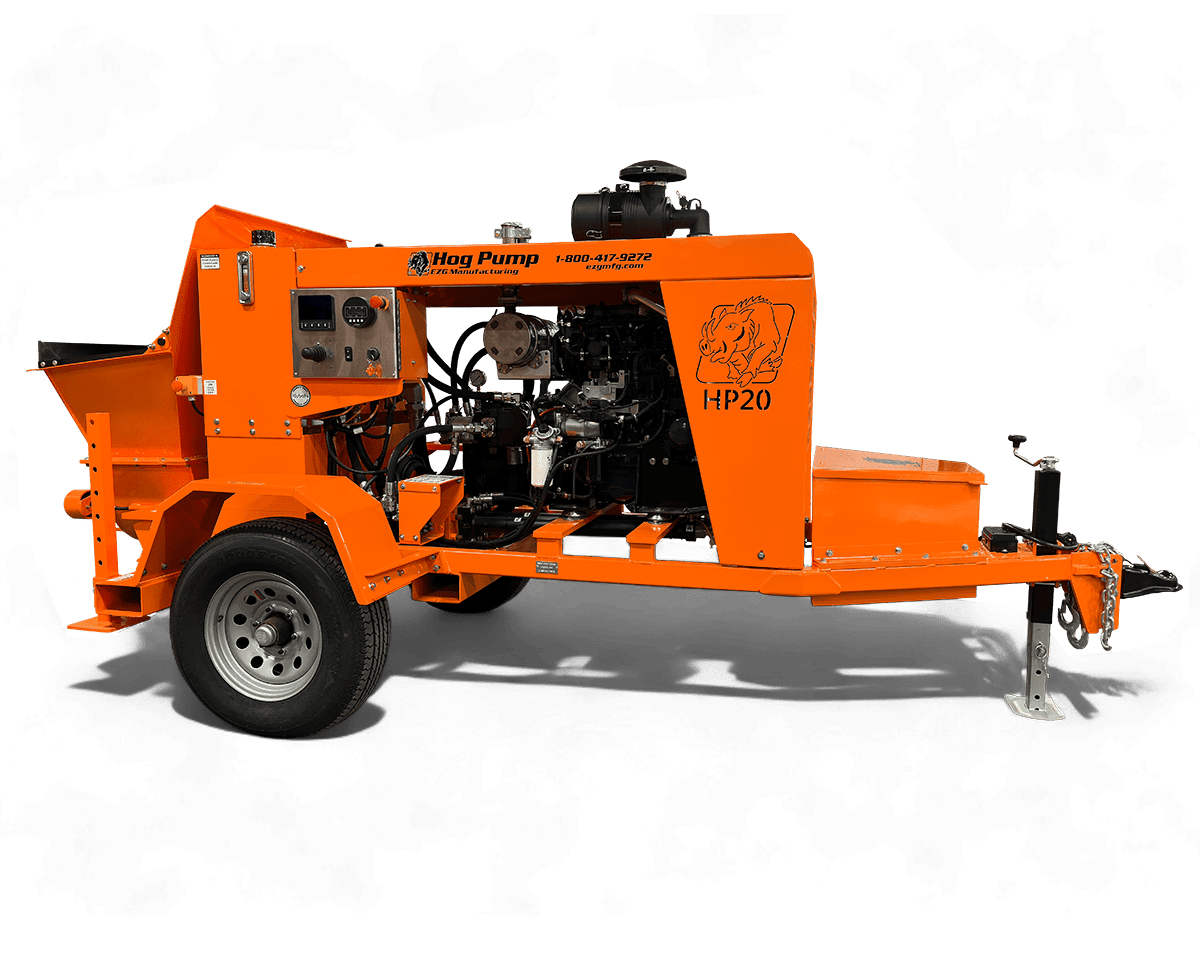

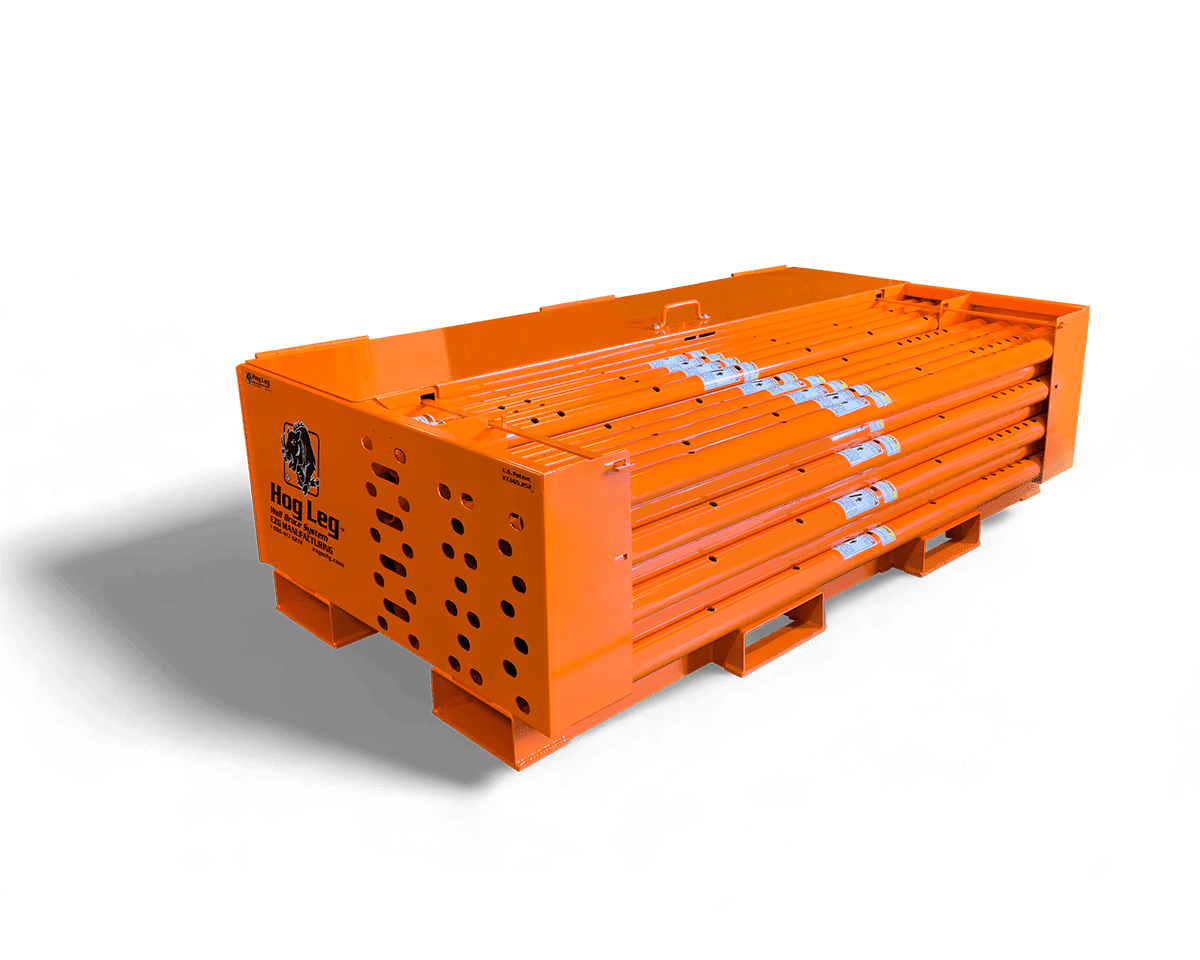

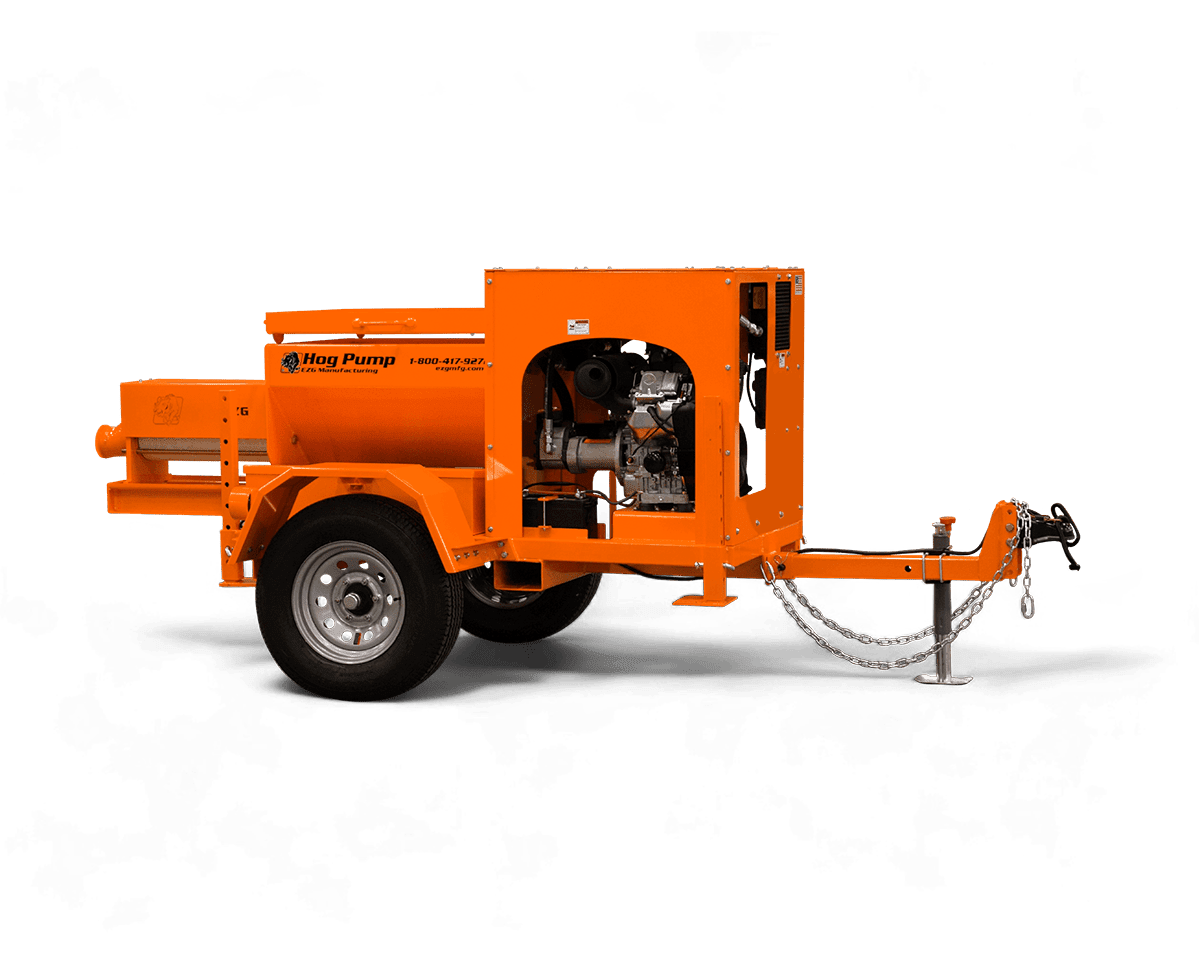

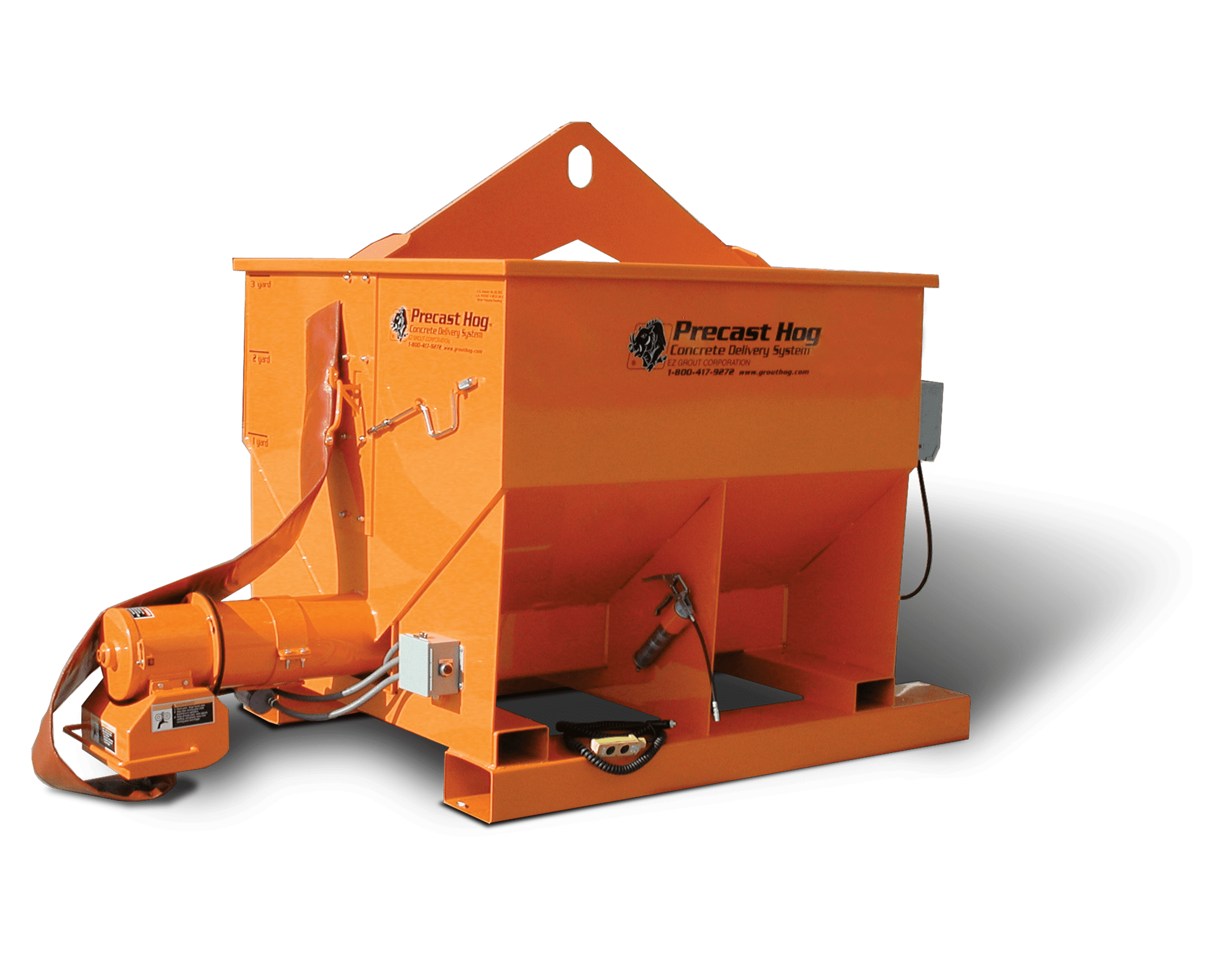

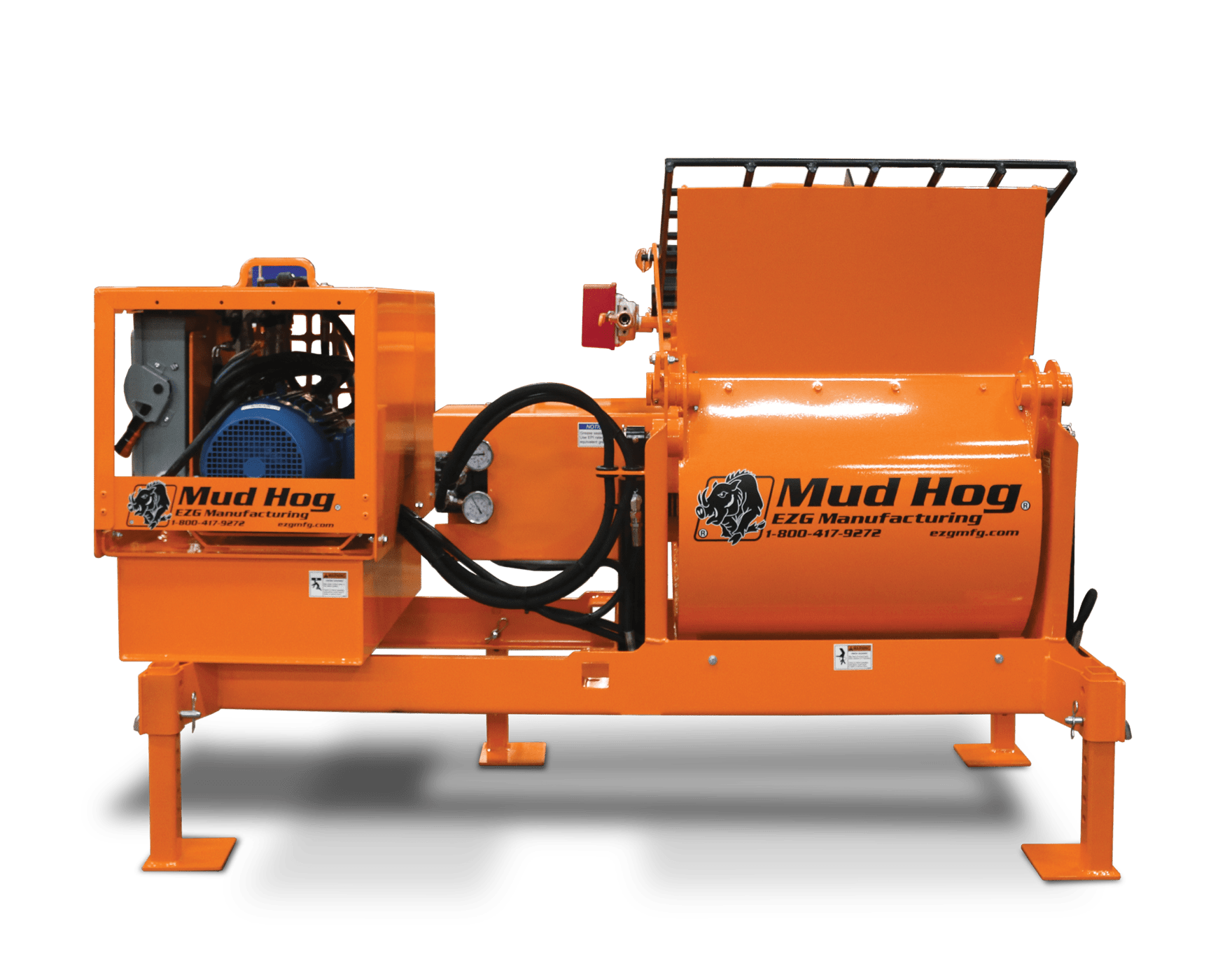

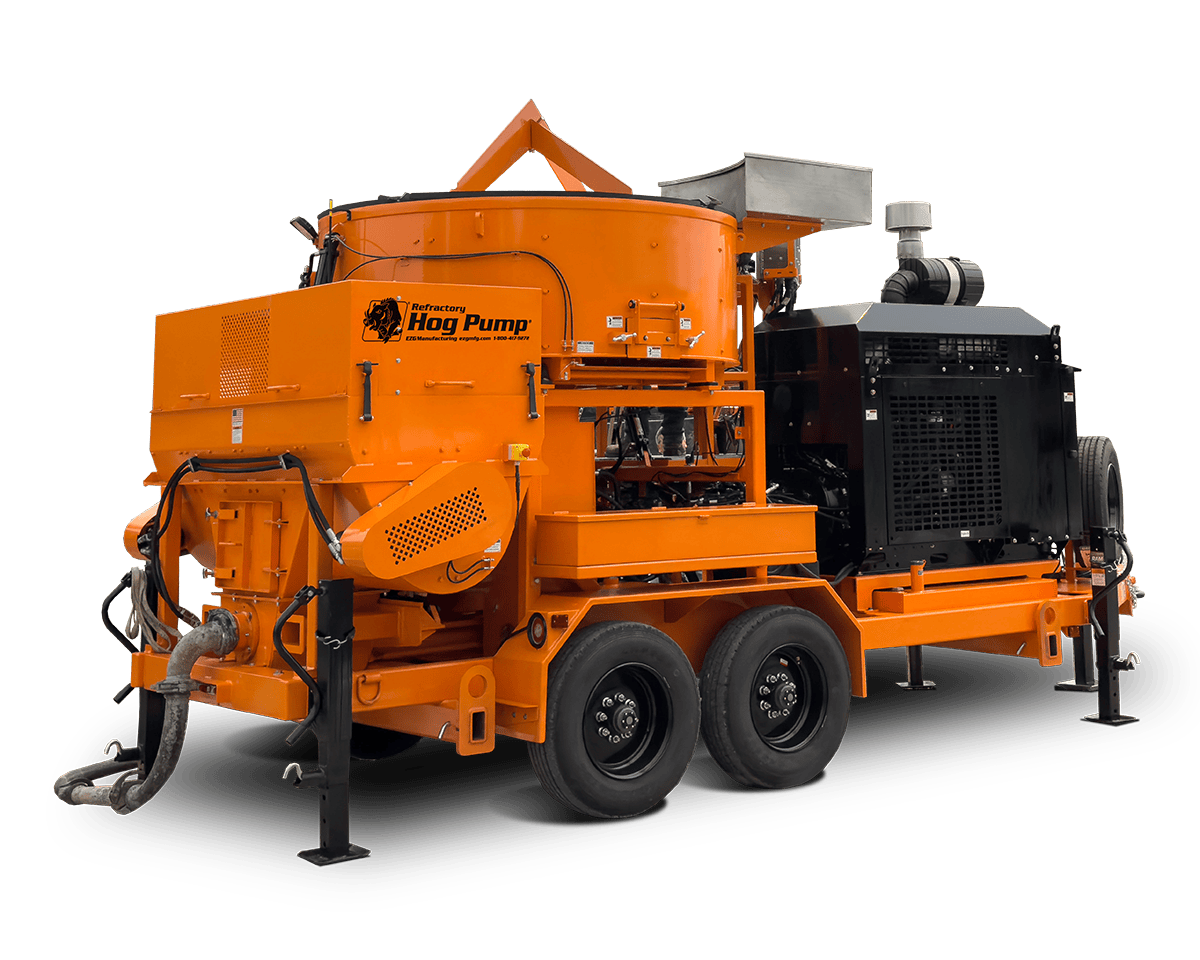

At EZG Manufacturing, CNC operators are a core part of our in-house team, supporting our ability to deliver fully finished, high-quality parts without delays or outsourcing.

Here’s a closer look at what CNC operators do and why they’re essential to modern manufacturing.

What Does a CNC Operator Do?

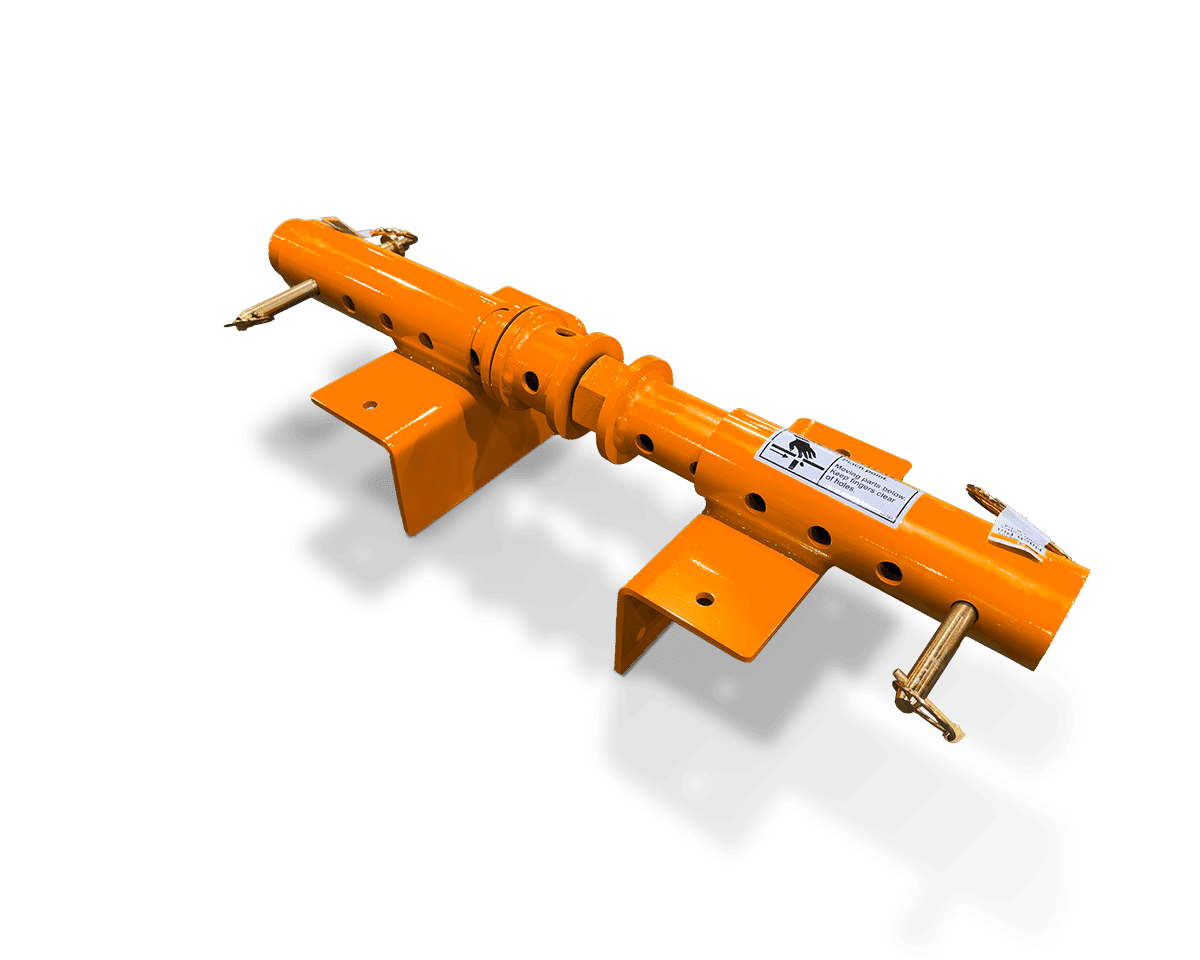

CNC machine operators are responsible for setting up, running, and maintaining machines that cut, shape, or drill materials like metal, plastic, or composites. These machines follow pre-programmed instructions to create precise components, but it’s the operator who keeps the process on track.

Common CNC operator responsibilities include:

- Loading and securing raw materials into CNC machines

- Starting and stopping machine cycles based on production specs

- Interpreting technical drawings and blueprint reading

- Measuring parts using precision tools to verify tolerances

- Replacing or adjusting cutting tools as needed

- Completing basic machine maintenance

- Documenting quality inspections and production output

- Cleaning and maintaining equipment

CNC operators are often the first line of defense against production issues. Their attention to detail prevents errors, rework, and costly downtime.

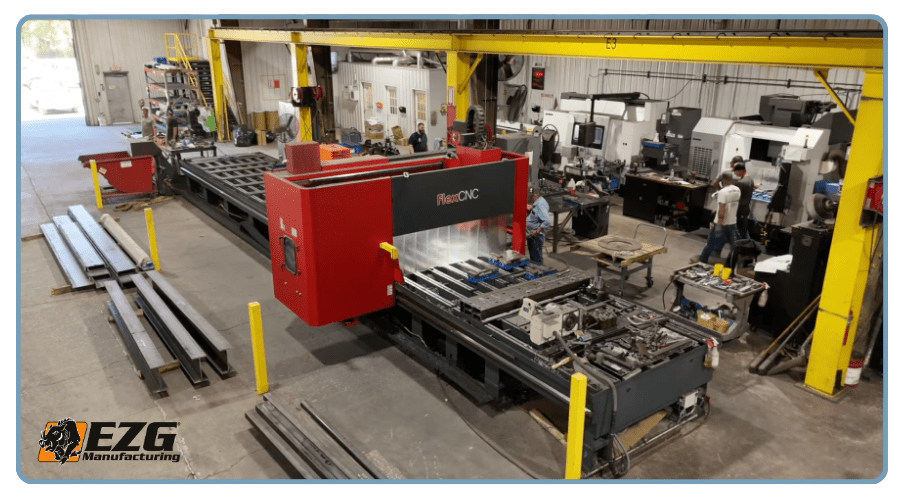

At EZG, our operators run everything from brake presses and milling machines to fiber lasers and our large-format FlexCNC machining center. They’re involved from the start of a part’s journey through final inspection and finishing.

How CNC Operators Fit into the Manufacturing Process

CNC operators are part of a larger team that includes engineers, CNC programmers, and welders. While programmers create the digital code, it’s the operator’s job to bring those programs to life by running the equipment safely and efficiently.

Their ability to troubleshoot tool paths, adjust setups, and flag programming issues helps avoid delays and ensures consistent quality. That hands-on skill set is valuable in any machine shop, but especially in a full-service operation like ours.

They contribute across multiple areas:

- Maintaining consistent output during long production runs

- Supporting custom fabrication with quick setups and changeovers

- Performing adjustments during runs to maintain part quality

- Collaborating with quality control to meet industry standards

Skills and Tools of a CNC Operator

Operating CNC machinery requires a blend of technical knowledge and hands-on expertise. Operators use both physical and digital tools to produce parts that meet exacting standards.

Necessary skills and tools include:

- Reading technical drawings and geometric dimensioning symbols

- Working with computer-aided manufacturing (CAM) software

- Using precision measuring instruments like micrometers and calipers

- Setting up and changing high-speed cutting tools

- Operating hand tools for part finishing or deburring

In addition, operators often work with hand tools to finish edges or remove burrs — especially in shops that produce parts requiring tight tolerances and clean finishes.

CNC Operator vs CNC Machinist vs CNC Programmer

It’s easy to confuse these roles, especially since they often overlap in smaller shops.

Here’s how they differ:

- CNC Operator: Machine tool operators focus on machine operation. They load materials, monitor runs, and check part quality. Typically, they follow a program written by others.

- CNC Machinist: Can do everything an operator does, but often has deeper experience with setup, tool selection, and machine calibration.

- CNC Programmer: Writes the machine code that tells the CNC equipment what to do. CNC programming uses computer software to create tool paths and sequences for part production.

In collaborative manufacturing shops like EZG, these roles work closely together. Operators support the programmers by reporting on tool performance and run conditions, creating a feedback loop that improves efficiency and part quality.

In some shops, one person may wear multiple hats. But in most production settings, these are distinct positions with unique responsibilities.

What Makes a Great CNC Operator?

Experience is important, but not the only factor. Great CNC operators bring a mindset that supports consistency and problem-solving on the floor. They contribute to production flow, solve problems in real time, and help maintain high standards for part quality and quality assurance.

Top qualities include:

- Strong problem-solving skills

- Ability to follow detailed instructions

- Focused attention to tolerance and finish

- Familiarity with different machine tools and material behaviors

- Communication skills with engineers, programmers, and other team members

Why CNC Operators Are More Valuable Than Ever

CNC machines are powerful, but they don’t run themselves. A qualified operator adds value at every stage of the production process, especially when:

- Tight tolerances are required

- Fast turnarounds are needed

- Complex machining or cutting setups are involved

- Final part quality affects downstream assembly or safety

Industries like aerospace, automotive, medical, and industrial equipment rely on CNC precision. The consistency and accuracy that CNC operators provide directly impacts the success of these operations.

That’s why EZG Manufacturing continues to invest in experienced operators and industry-leading equipment. From laser-cutting parts to multi-step machining projects, our team delivers accuracy, consistency, and reliable output at scale.

A Day in the Life: CNC Operators at EZG Manufacturing

Our CNC operators handle a wide range of projects, from small precision parts to large structural components. They use advanced equipment like the Mazak 10K Fiber Laser and our FlexCNC series to machine parts up to 40 feet long with pinpoint accuracy.

They work with steel, aluminum, and specialty metals. They quickly change tools, inspect finishes, and coordinate with our in-house powder coating and wet paint operations. The result? A complete part that meets spec — without needing to leave our facility.

It’s all part of our commitment to being a true one-stop shop for custom metal fabrication.

The Bottom Line

CNC operators don’t just press buttons, they bring parts to life. Their knowledge, skill, and judgment make a difference in every product that leaves the shop.

At EZG Manufacturing, we rely on experienced CNC operators to meet demanding project specs and tight deadlines — all while keeping fabrication in-house.

Looking for a contract manufacturing partner you can trust? Contact EZG Manufacturing to see how our people, processes, and precision equipment can support your next project.