In an era where sustainability intersects with efficiency, the fusion of green energy projects and advanced construction methods is evident. From sprawling solar farms to intricate fencing installations, the demand for cutting-edge equipment solutions has become paramount. This article explores how innovative attachments from EZG Manufacturing are reshaping the landscape of equipment efficiency and productivity.

The Solar Farm Saga: Pioneering Progress in Pickaway County

The story of the Yellowbud Solar Farm in Pickaway County, Ohio, stands as a testament to the evolving landscape of green energy initiatives. This ambitious project represents a recent milestone in renewable energy development. Spanning a vast 2,040-acre area, the solar farm is poised to generate 274 megawatts of clean energy through ground-mounted photovoltaic modules. However, beyond the technological marvel of solar panels lies a crucial aspect often overlooked: security fencing.

As the project commenced, the need for robust fencing solutions became evident. With nearly 20 miles of fencing and 14,000 wooden posts to be installed, efficiency and safety were paramount. Enter Kiewit Corporation, entrusted with the monumental task of construction, and their strategic partner, EZG Manufacturing. Leveraging EZG’s expertise in fencing equipment, Kiewit embarked on a journey to revolutionize the fencing installation process.

Innovative Solutions for Fencing Efficiency

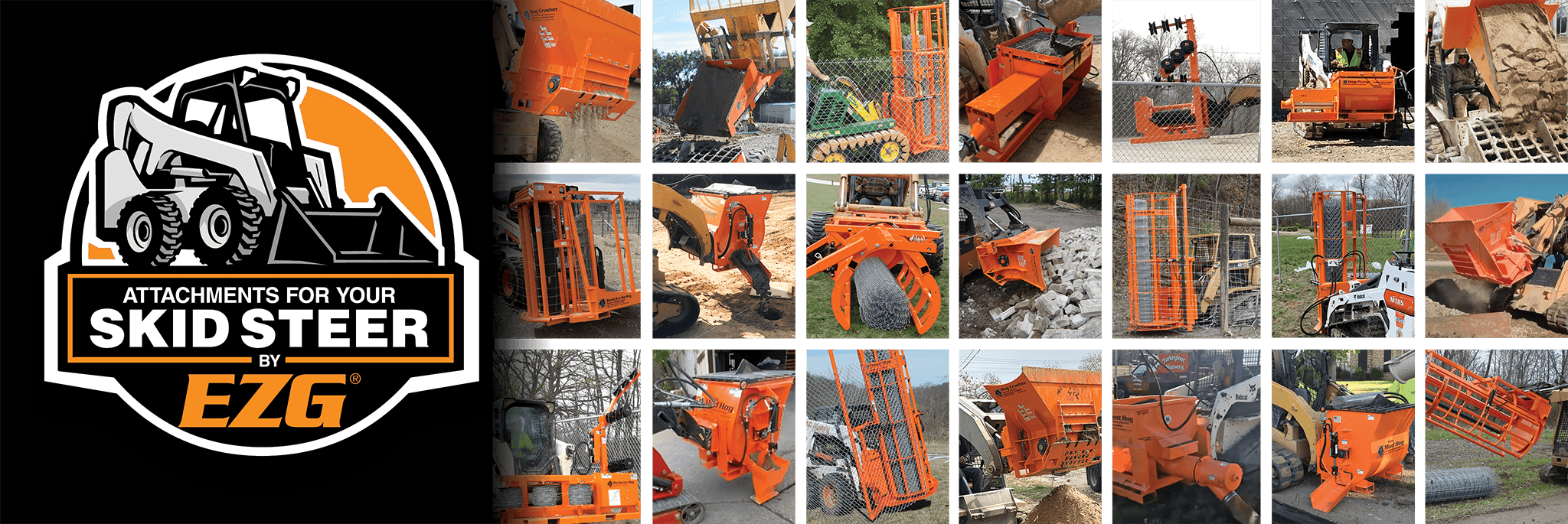

At the heart of Kiewit’s fencing strategy lay a suite of EZG attachments designed to maximize productivity. The Fence Hog®, Barbwire Hog®, and Stretch-N-Go® Barbwire Dispenser emerged as indispensable tools in the arsenal, offering unparalleled efficiency and ease of operation. From handling heavy rolls of fencing to dispensing barbwire with precision, these attachments exemplified the synergy between innovation and practicality.

Moreover, the logistical challenges posed by the project’s remote location necessitated creative solutions. Traditional cement trucks were deemed impractical, prompting Kiewit to explore alternative methods. Enter the EZG Mobile Mud Hog® mixer, a game-changer in on-site cement mixing. Compatible with standard skid steers, this versatile attachment enabled seamless cement production along the fence lines, eliminating the need for cumbersome trucks and minimizing environmental impact.

A Paradigm Shift in Fencing Efficiency: The White Paper on Fence Hog Equipment

Beyond the confines of solar farm construction, the fencing industry at large stands poised for transformation. Traditional methods, characterized by labor-intensive processes and ergonomic challenges, are ripe for innovation. EZG’s Fence Hog equipment emerges as a beacon of progress in this landscape, offering a pathway to enhanced productivity and safety. The industry is ripe for change, with traditional methods plagued by challenges such as labor costs, manual lifting injuries, and logistical inefficiencies.

As outlined in the white paper on Fence Hog equipment, these challenges are significant and widespread. The global fencing industry reached a value of nearly $30 billion in 2019 and is forecast to have a compounded annual growth rate of more than 5% through 2027. Heightened safety and security concerns resulting from political and social unrest are also increasing the demand for reliable fencing systems.

Labor costs remain a significant factor, with the U.S. national average for a fence installer ranging from $28,287 for entry level to $44,570 for senior-level positions1. Moreover, manual lifting injuries pose a threat to worker safety, with musculoskeletal disorders involving the back accounting for 38.5% of all work-related musculoskeletal disorders2. Logistical inefficiencies further compound these challenges, leading to delays, increased costs, and reduced profitability for fencing projects.

However, the introduction of the Fence Hog represents a turning point for the industry and equipment operators alike. By streamlining operations and mitigating workplace hazards, the Fence Hog offers a solution to these longstanding issues. Its mechanical simplicity and short learning curve make it an invaluable asset for increasing efficiency and reducing injuries. As the fencing industry embraces innovation and adopts cutting-edge equipment solutions like the Fence Hog, equipment operators find themselves at the forefront of a new era of efficiency and safety.

Expanding Horizons: Beyond Fencing

The far-reaching impact of EZG’s attachments extends beyond traditional fencing applications, marking the onset of a new era defined by versatility and efficiency in construction. As the Fence Hog and its counterparts revolutionize the fencing industry, they open avenues for innovation across diverse sectors. EZG’s extensive range of attachments, from the Mobile Mud Hog mixer to the Fencer’s Cement Hog® and Hog Crusher® material recycling attachment, represents the pinnacle of technological advancement in construction equipment.

Diversifying Applications, Maximizing Efficiency

The Mobile Mud Hog mixer stands as a testament to the ingenuity of modern construction equipment. Designed for seamless integration with standard skid steers, this versatile attachment redefines on-site materials mixing, transcending the limitations of traditional cement trucks. Whether navigating rugged terrain or confined spaces, the Mobile Mud Hog empowers operators to produce a high-quality mix on demand, enhancing project efficiency and minimizing environmental impact.

Similarly, the Fencer’s Cement Hog represents a paradigm shift in the realm of concrete placement. Engineered for precision and versatility, this innovative attachment streamlines the process of pouring and distributing concrete or sand along fence lines. By eliminating the need for manual labor and cumbersome equipment, the Fencer’s Cement Hog optimizes workflow efficiency, reducing project timelines and labor costs.

In parallel, the Hog Crusher material recycling attachment embodies the ethos of sustainability and resource optimization. By repurposing construction waste into reusable aggregate, this groundbreaking attachment not only minimizes landfill waste but also reduces the need for virgin materials, thereby mitigating environmental impact. From demolition debris to concrete rubble, the Hog Crusher unlocks a wealth of opportunities for eco-conscious construction practices, fostering a more sustainable approach to project management.

Pushing Boundaries, Unlocking the Potential of Equipment Versatility

The implications of EZG’s innovative attachments extend far beyond their immediate applications. As owners and operators of skid steers, excavators, track loaders, and stand-on units, users can leverage these attachments across a spectrum of tasks. From fencing installations to job-site material recycling and beyond, the versatility of EZG equipment opens doors to new markets and revenue streams. By embracing innovation and diversifying service offerings, operators position themselves at the forefront of industry evolution. Whether optimizing productivity, enhancing safety protocols, or exploring new avenues for growth, EZG’s attachments empower users to push the boundaries of equipment efficiency. As pioneers of progress, operators have the opportunity to redefine the future of construction, one attachment at a time.

Conclusion: Pioneering Progress Through Innovation

To summarize, the revolutionary impact of EZG’s attachments extends far beyond the realm of fencing, ushering in a new era of efficiency and sustainability in construction. The convergence of green energy projects and advanced construction methods provides fertile ground for innovation, as exemplified by the Yellowbud Solar Farm project and EZG’s pioneering attachments. From the Mobile Mud Hog mixer to the Fencer’s Cement Hog and Hog Crusher material recycling attachment, each innovation represents a testament to the power of ingenuity and technological advancement. By embracing innovation and harnessing the power of versatile equipment solutions, we can chart a course towards a more sustainable and prosperous future.

¹Economic Research Institute– 2021

²U.S. Bureau of Labor Statistics, Employer-Reported Workplace Injuries and Illnesses – 2016