In landscaping, time isn’t just money – it’s opportunity. Every hour saved means one more project completed, one more satisfied client, and one less day of wear on your crew. The most successful contractors know that investing in the right tools pays off fast. The right piece of equipment doesn’t just make work easier; it keeps jobs on schedule, reduces fatigue, and protects your bottom line.

Why Efficiency Matters in Landscaping and Hardscaping

Labor is the largest expense for any landscaping business. Every delay, from hauling materials to correcting uneven pavers, cuts directly into profits. Even small inefficiencies across multiple projects can add up to weeks of lost productivity each year.

By focusing on efficient tools and processes, crews can complete more work with the same number of people. The result: higher profits, fewer callbacks, and a safer, less stressful jobsite.

Time vs. Profit Relationship

| Crew Size | Avg. Hours per Job | Profit Margin | Margin with Time-Saving Equipment |

|---|---|---|---|

| 3-person | 40 hrs | 20% | 30–35% |

| 5-person | 60 hrs | 18% | 28% |

The takeaway is simple: small improvements in time management create major gains in profitability.

The Most Time-Consuming Parts of Landscaping Projects

Before you can save time, it helps to identify where it’s being lost. Across hundreds of projects, certain phases consistently slow down crews, drain energy, and increase costs.

Base Preparation and Compaction

A strong foundation starts with proper compaction. But manual tamping or low-powered plate compactors require multiple passes to get results. That means more time, more labor, and a higher chance of uneven settling later. Correcting these problems after installation can double your total hours on the job.

Material Transport and Handling

Few tasks waste more time than moving materials. Hauling stone, soil, or sand by hand or with undersized wheelbarrows can take up to a third of the workday. Fatigue builds up fast, leading to slower movement and higher risk of spills or injuries.

Cutting and Shaping Stone or Block

Precision cutting is one of the slowest parts of any hardscape job. Inaccurate or inconsistent cuts lead to wasted blocks and time spent fitting or replacing materials. Crews using manual methods can spend more time cutting than installing.

Site Protection and Cleanup

Jobsites without ground protection often turn into repair zones. Deep ruts, damaged turf, and leftover debris can take hours to fix after installation. Proper protection at the start saves valuable cleanup time at the end.

These areas may seem minor on their own, but across multiple projects, they can add up to hundreds of hours every season.

Tools and Equipment That Save Time and Money

Every one of these challenges has a solution. The right tools not only speed up work but also improve consistency and reduce wear on your crew. The faster a project is completed, the faster a crew can move on to the next, which means higher yearly revenue without increasing labor costs.

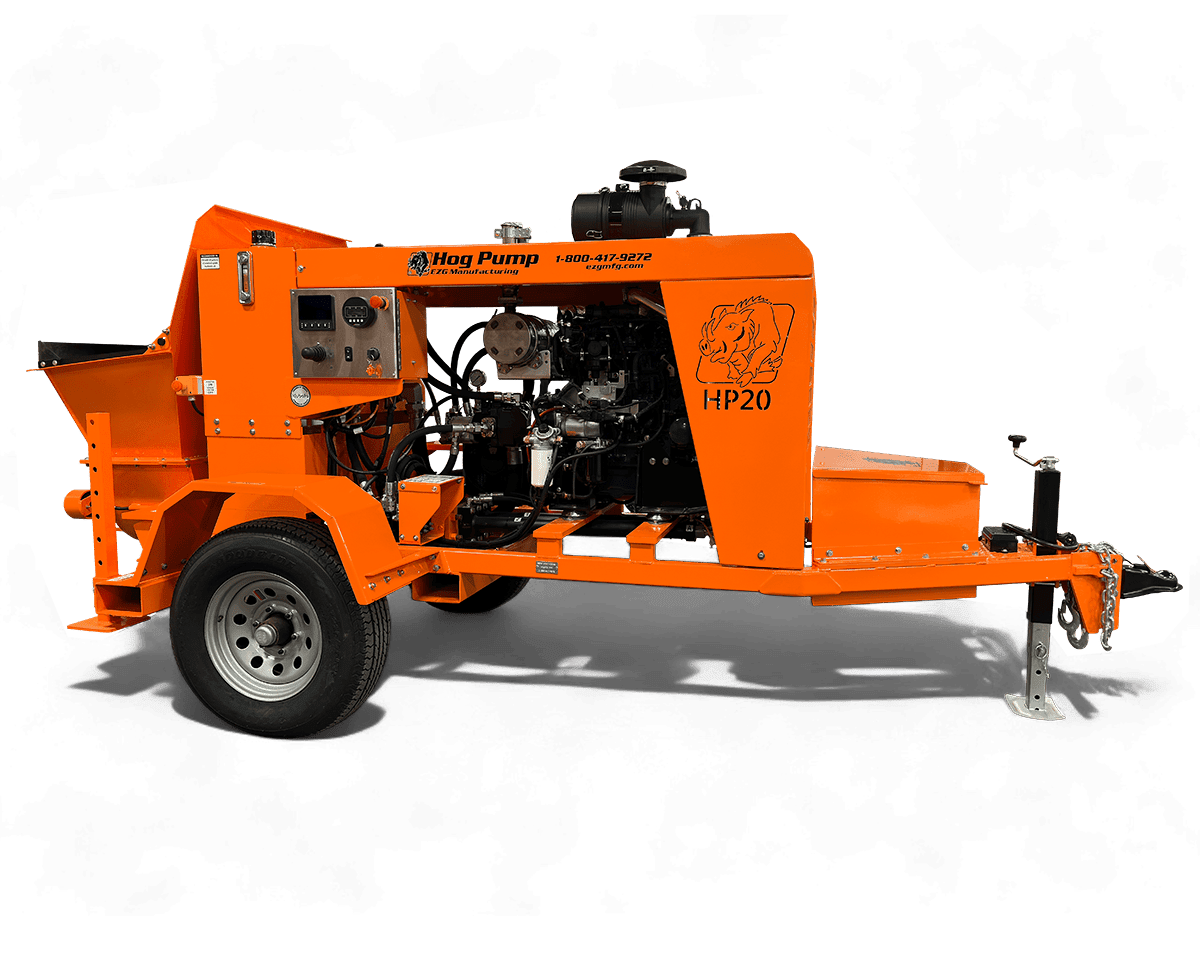

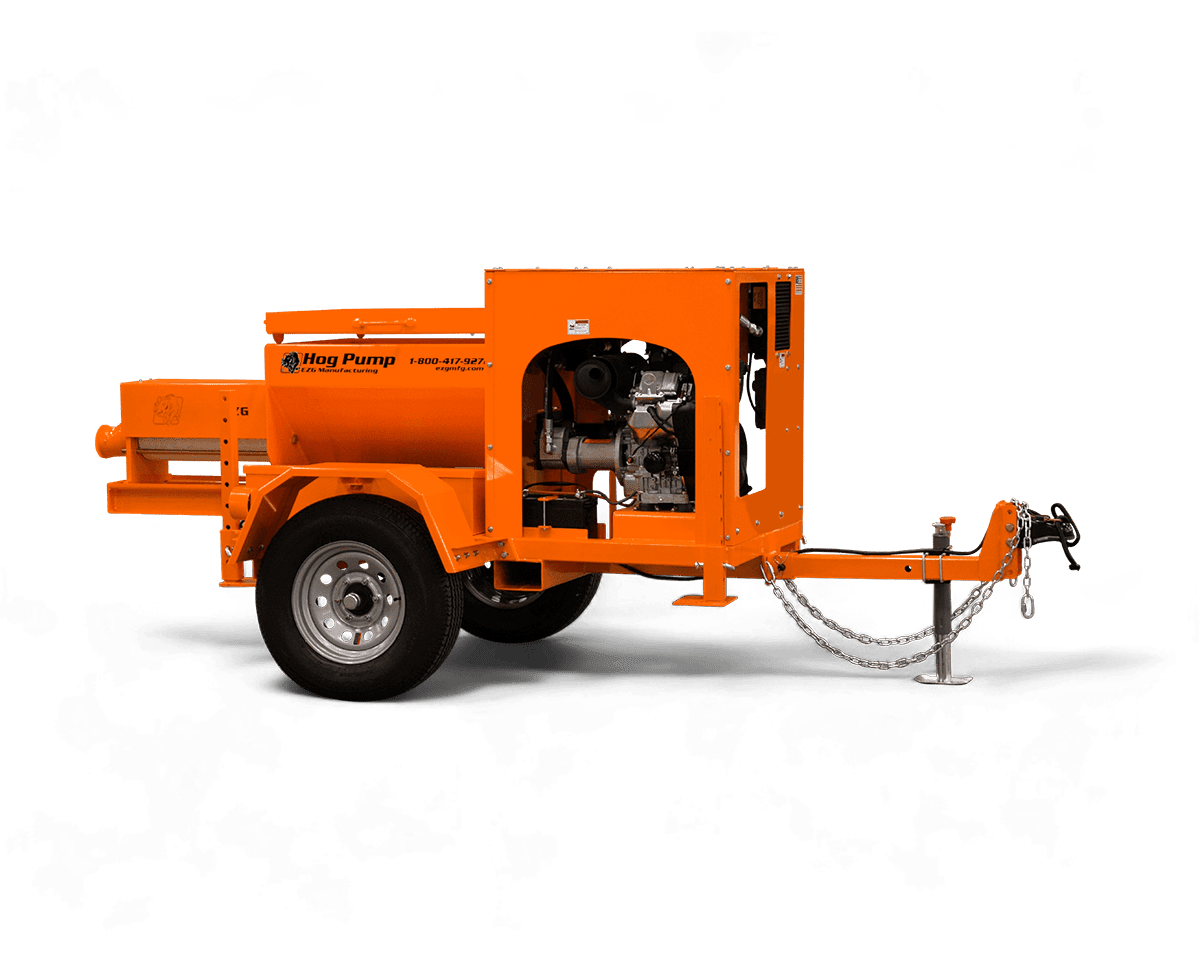

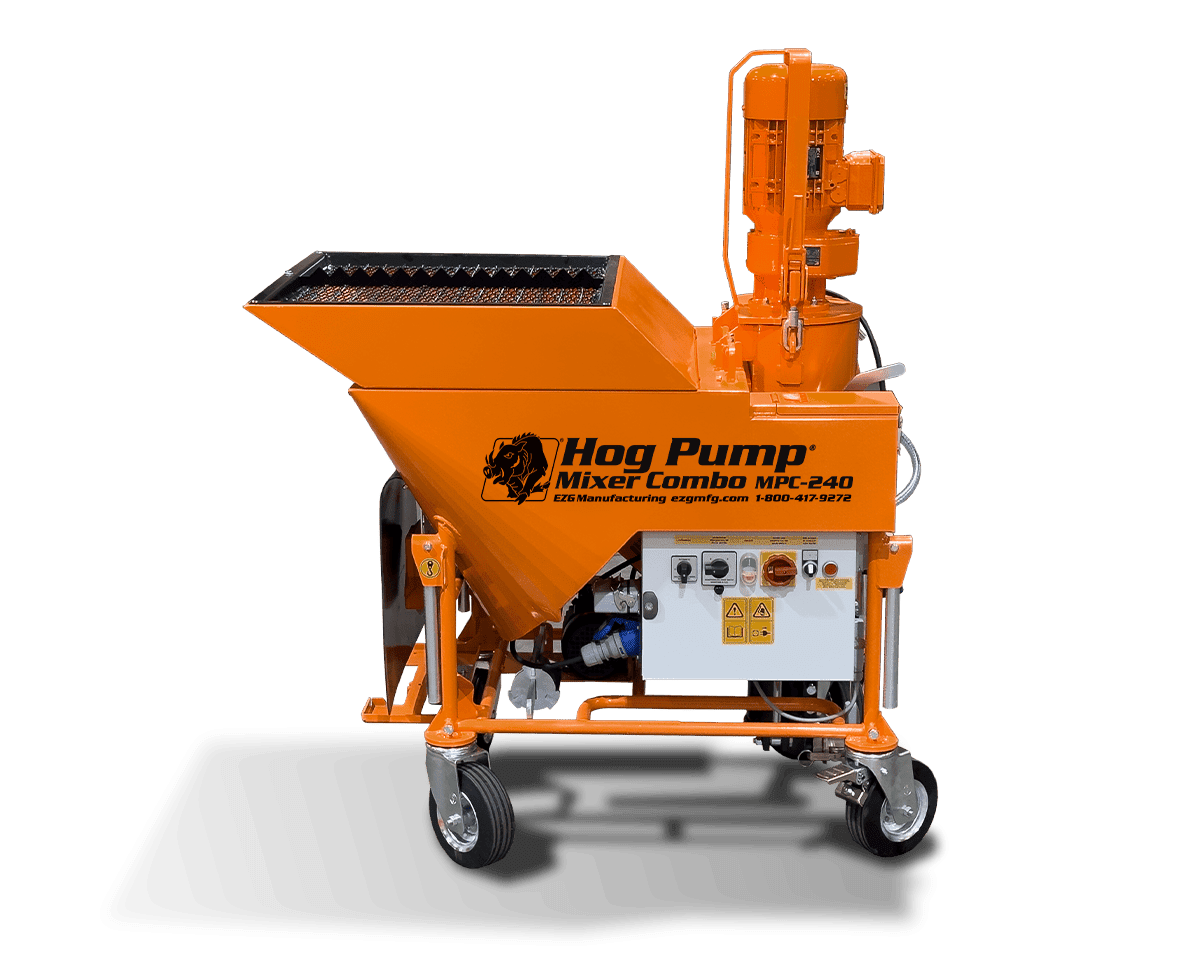

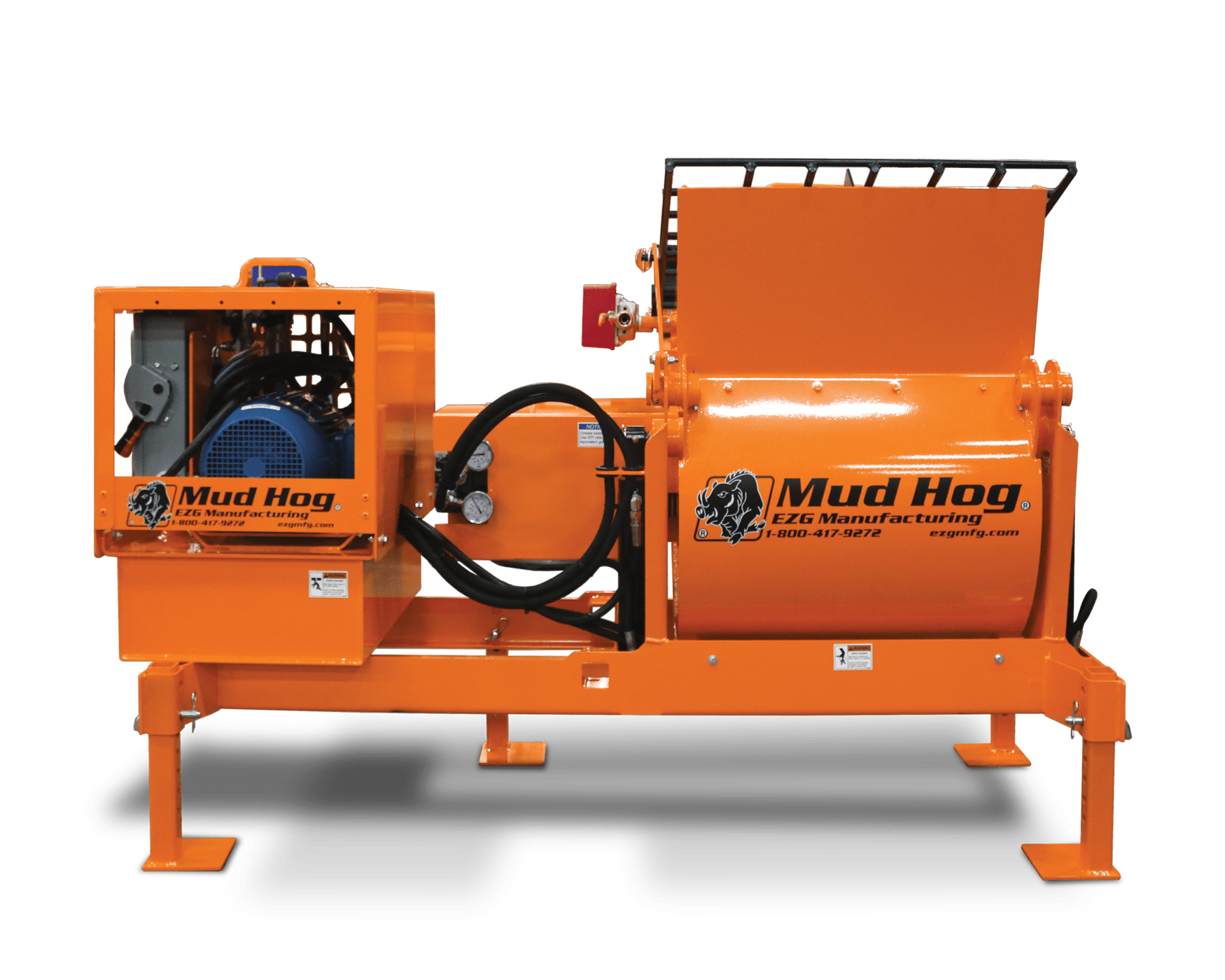

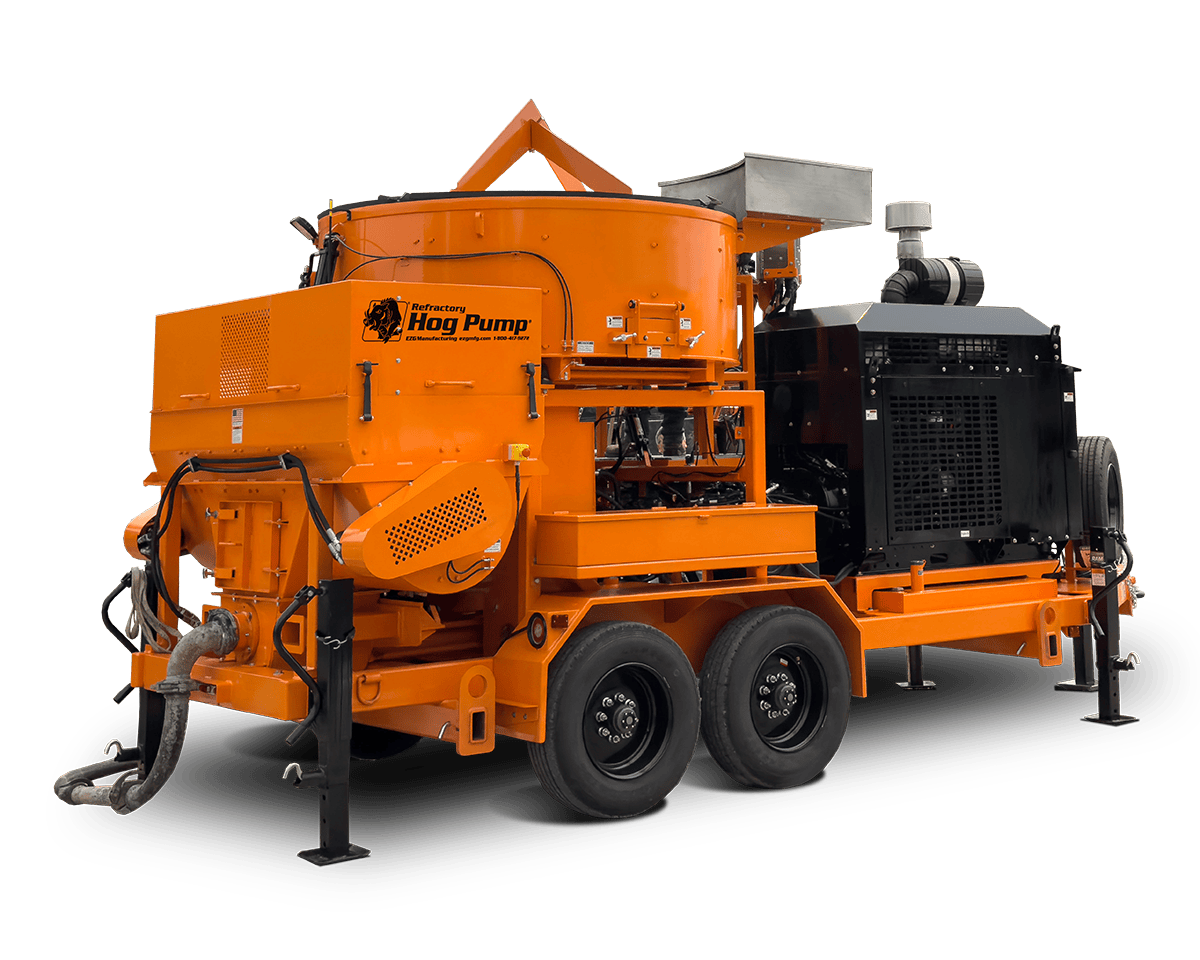

EZG Landscape Tools Built to Maximize Productivity

EZG Manufacturing builds equipment that addresses these exact challenges. Each machine is designed to help landscapers and hardscapers complete more work in less time, without sacrificing quality or durability.

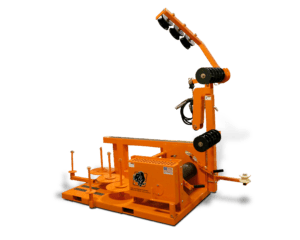

Roller Paver Compactor

When it comes to finishing pavers, traditional plate compactors can crack or chip surfaces. EZG’s Roller Paver Compactor is built specifically for paver installation. Its rubber-coated rollers glide across delicate materials, compacting evenly without surface damage.

Crews save hours by eliminating rework and achieving perfect compaction in fewer passes.

| Feature | EZG Roller Paver Compactor |

|---|---|

| Centrifugal Force | 2,315 lbs |

| Operating Weight | 271 lbs |

| Engine | Honda GX160 (4.8 hp) |

| Best Use | Paver compaction, finish work |

This tool turns one of the most tedious parts of hardscaping into a quick, reliable process.

Reversible Vibratory Plate Compactor

For base prep, EZG’s Reversible Vibratory Plate Compactor delivers serious performance. Its bidirectional motion allows for smooth transitions between passes, reducing turnaround time and operator fatigue.

Producing up to 9,000 pounds of compaction force, this model is ideal for gravel, sand, and crushed stone bases, giving you a stable, uniform foundation with less effort.

Why It Saves Time:

- Covers larger areas in fewer passes

- Easier to maneuver around edges and corners

- Reduces base repair or rework after installation

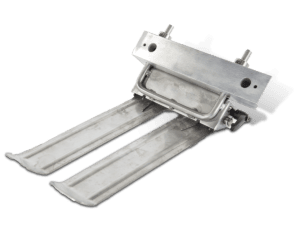

Krack Hog Precision Splitter

Cutting and shaping blocks doesn’t have to slow your crew down. The Krack Hog Precision Splitter cleanly splits retaining wall blocks and pavers without dust, noise, or wasted material.

Instead of using a saw or chisel, operators can split pieces in seconds, keeping projects moving smoothly. The Krack Hog produces consistent edges that fit tight without constant adjustments.

Why Contractors Use It:

- Speeds up wall and edging work

- Reduces wasted blocks

- Built from high-tensile steel for long-term reliability

EZG Wheelbarrows

Material transport is one of the most time-draining parts of a jobsite, but EZG’s contractor-grade wheelbarrows help crews move faster with less effort. These wheelbarrows feature balanced steel frames, deep trays, and heavy-duty construction that can handle concrete, stone, and wet soil without bending or tipping.

| Feature | EZG Wheelbarrow | Standard Wheelbarrow |

|---|---|---|

| Capacity | Higher-volume tray | Smaller load size |

| Durability | Steel frame, contractor-grade | Plastic or thin metal |

| Balance | Centered for stability | Front-heavy |

| Lifespan | Multi-season | Shorter service life |

Fewer trips mean more time spent installing, not hauling.

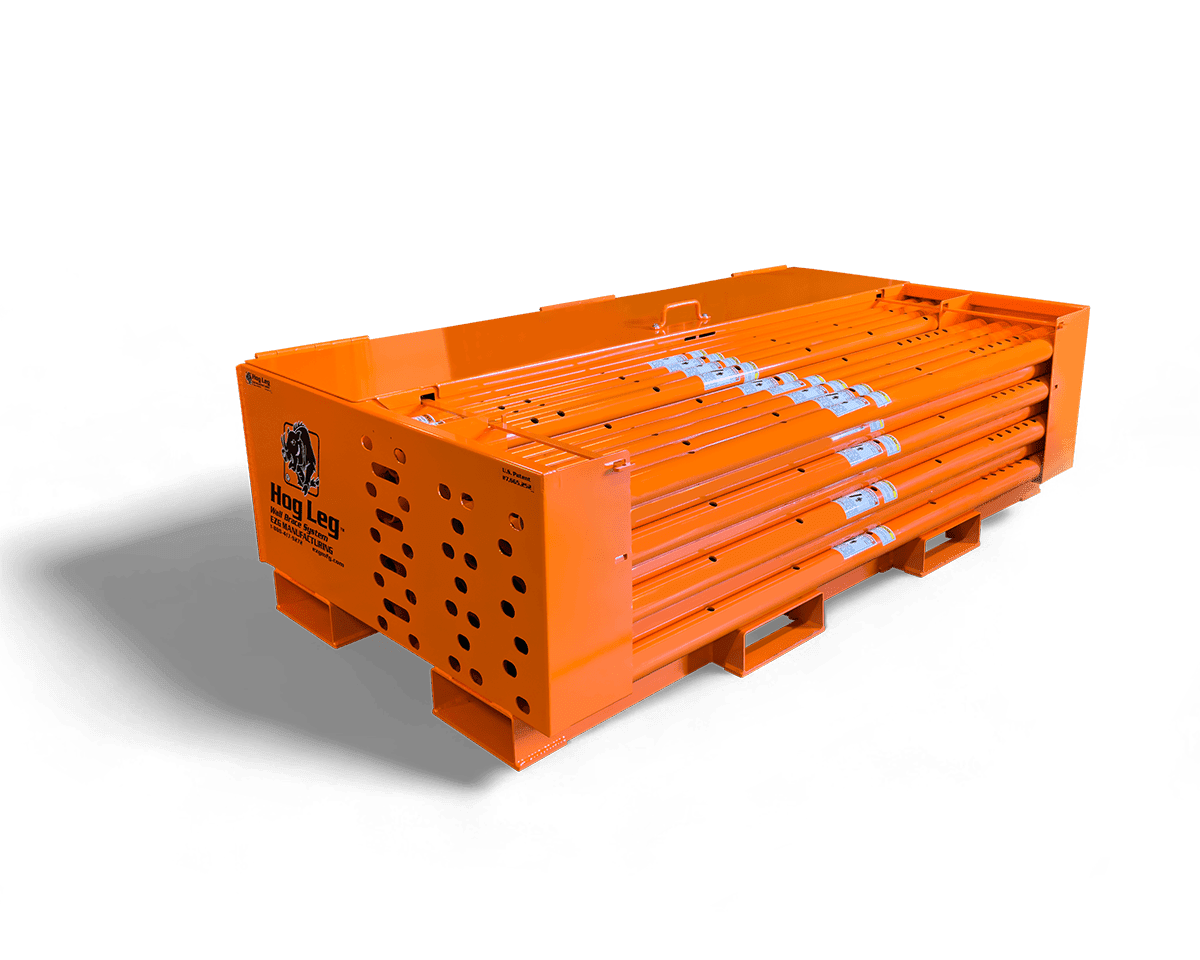

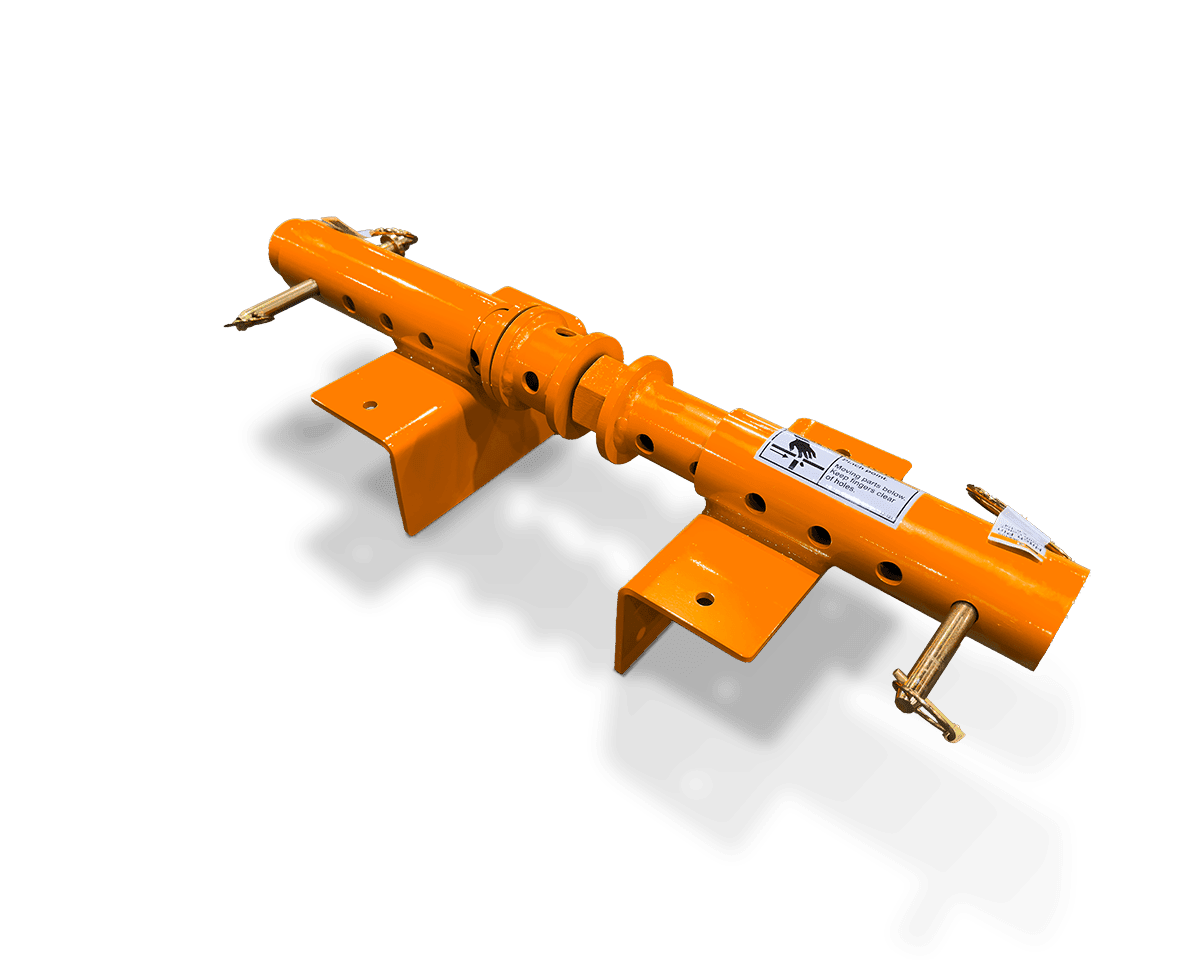

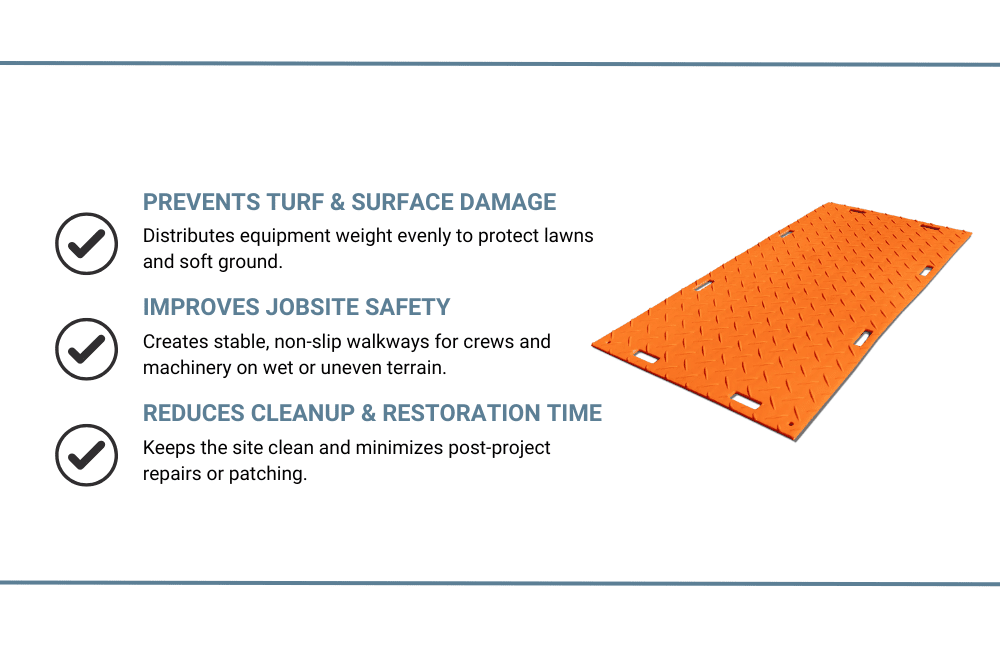

Hog Traks Ground Protection Mats

Protecting lawns and surfaces saves hours of cleanup. Hog Traks Ground Protection Mats distribute the weight of equipment and vehicles, preventing ruts and surface damage. These mats improve traction and safety on wet or uneven ground, allowing crews to move freely without slowing down.

Benefits:

- Faster setup and teardown

- Less repair work after completion

- Safer footing and smoother workflow

Additional Tools That Increase Daily Efficiency

While EZG’s heavy-duty equipment takes care of the toughest tasks, small upgrades across your tool lineup can make a big difference in productivity.

Cutting and Layout Tools

Precision starts with proper layout and cutting. Masonry and cutoff saws fitted with diamond blades deliver faster, cleaner cuts that reduce waste and rework. Pairing these with laser levels or smart measuring tools helps crews maintain consistent slopes and layouts across large projects. Screed rails and edge restraints keep base layers even, cutting down on time spent correcting grades later. Together, these tools create a smoother workflow from prep to installation.

Load-Carrying and Transport Equipment

Material handling is one of the biggest time drains in landscaping, but the right transport equipment turns it into a strength. Motorized material buggies and compact loaders move large quantities of soil, stone, or sand quickly across the jobsite, freeing up crew members for more precise work. When used alongside EZG Wheelbarrows, crews can easily shift between bulk hauling and tight-area transport, keeping materials moving efficiently from start to finish.

Ergonomic Hand Tools That Reduce Strain

Even small adjustments in tool design can have a big impact on productivity. Long-handled shovels, rakes, and tampers promote better posture during long workdays and help prevent back and wrist strain. Shock-absorbing grips add comfort, reducing the physical toll on workers who spend hours shaping, leveling, or tamping surfaces. For hardscapers, alignment tools designed for quick paver adjustments make it easier to keep patterns straight without constant bending or hammering.

Safety and Organization Tools

Jobsite efficiency also depends on preparation and organization. Personal protective gear such as gloves, knee pads, and hearing protection keeps crews comfortable and focused on their tasks. Organized storage systems help prevent wasted time spent looking for misplaced gear. Having equipment properly stored and accessible at all times supports a faster, safer work environment and reduces downtime between tasks.

How to Choose the Right Tools for Your Crew

Choosing the right equipment comes down to project size, crew capacity, and long-term value. Here are a few factors to consider:

- Match equipment power and size to your average job type.

- Invest in multi-use tools that can handle several applications.

- Prioritize operator comfort and reliability over short-term savings.

- Calculate long-term savings. A good tool pays for itself quickly through reduced labor hours.

Maintenance Tips for Long-Lasting Equipment

Reliable performance depends on regular maintenance. Simple daily care keeps tools in good condition for years.

- Clean compactors, splitters, and wheelbarrows after each use.

- Check oil, filters, and belts regularly.

- Replace worn components before they cause downtime.

- Store equipment under cover to prevent rust or weather damage.

Routine care doesn’t take long but pays off through fewer repairs and consistent performance year after year.

Efficiency That Pays Off

Every landscaping project depends on teamwork, timing, and trust in your tools. The difference between a long week and a profitable one often comes down to having the right equipment on hand.

EZG Manufacturing designs machines built to take on the toughest jobs, from compactors that deliver perfect paver finishes to wheelbarrows that move more material with less strain. These tools are built for hardworking crews who value results, durability, and long-term savings.

Ready to work smarter? Explore EZG Manufacturing’s Hardscape Equipment. Lineup to find tools that save time, reduce labor, and deliver lasting value on every job.