From potato chips to packaged meals, every food product starts with the same foundation: reliable equipment. The right machinery keeps your line moving, protects food safety, and supports consistent product quality.

Choosing food processing equipment is a long-term decision that affects efficiency, maintenance, and compliance… all factors that directly impact profitability.

Understanding Food Processing Equipment

Behind every snack, beverage, or frozen entrée is a carefully designed production line made up of specialized systems. Food processing equipment includes everything from mixers and conveyors to blenders, hoppers, and packaging systems. Each piece plays a role in preparing, cooking, or handling products across different stages of production.

For many food manufacturers, these machines represent the heartbeat of their operation. The right setup depends on your processing line, product type, desired throughput, and scale of your facility. Below is an overview of common food processing equipment categories:

| Equipment Type | Function | Common Materials | Typical Use |

|---|---|---|---|

| Mixers & Blenders | Combine ingredients | Stainless Steel | Dough, sauces |

| Conveyors | Move products efficiently | Stainless Steel, Polymer | Bakery, meat lines |

| Hoppers & Tanks | Store or dispense bulk materials | Stainless Steel | Dry or wet ingredients |

Leading manufacturers like EZG Manufacturing engineer durable, hygienic systems built for long-term reliability and simplified operation. This helps food processors maintain consistent performance from start to finish.

Sanitation and Hygienic Design

What Makes Food Processing Equipment Hygienic?

Cleanability is one of the most important considerations in the food industry. Poor design can create hidden areas where residue and bacteria accumulate, leading to contamination risks. That’s why hygienic design is central to every piece of food equipment built for today’s processors.

Look for these hygienic design elements:

- Smooth welds and crevice-free joints prevent bacterial growth.

- Drainable frames eliminate standing liquid after washdowns.

- Sloped surfaces help liquids flow away from product zones.

- Tool-free disassembly supports quick cleaning and inspection.

All food product contact surfaces must resist corrosion and meet all federal regulation standards. Clean-in-place (CIP) systems, non-toxic gaskets, and polished stainless finishes keep sanitation simple and consistent.

| Hygienic Feature | Function | Benefit |

|---|---|---|

| Seamless Welding | Prevents residue buildup | Safer food contact |

| Sloped Frames | Improves drainage | Faster cleaning |

| Removable Guards | Simplifies access | Reduces downtime |

| CIP System | Automated wash cycles | Consistent sanitation |

Hygienic design isn’t just about compliance. It’s about preventing contamination issues before they affect your finished product or production schedule.

Material Durability and Corrosion Resistance

What Materials Are Best for Food Processing Equipment?

Material selection determines how well your system performs and how long it lasts. Most food processing industry equipment is built from stainless steel because of its strength, corrosion resistance, and ease of cleaning.

- 304 Stainless Steel is widely used for general food processing applications and resists corrosion in most environments.

- 316 Stainless Steel offers resistance to salt, acids, and aggressive cleaning agents; ideal for seafood, sauces, or acidic foods.

| Material | Corrosion Resistance | Typical Use | Notes |

|---|---|---|---|

| 304 Stainless | Excellent | General food contact | Cost-effective choice |

| 316 Stainless | Superior | Acidic or salty environments | Best for longevity |

| HDPE | Good | Non-contact surfaces | Used in conveyors and cutting boards |

Using the right material helps protect product quality while maximizing operational efficiency. It also reduces long-term maintenance costs and supports consistent performance across your entire plant.

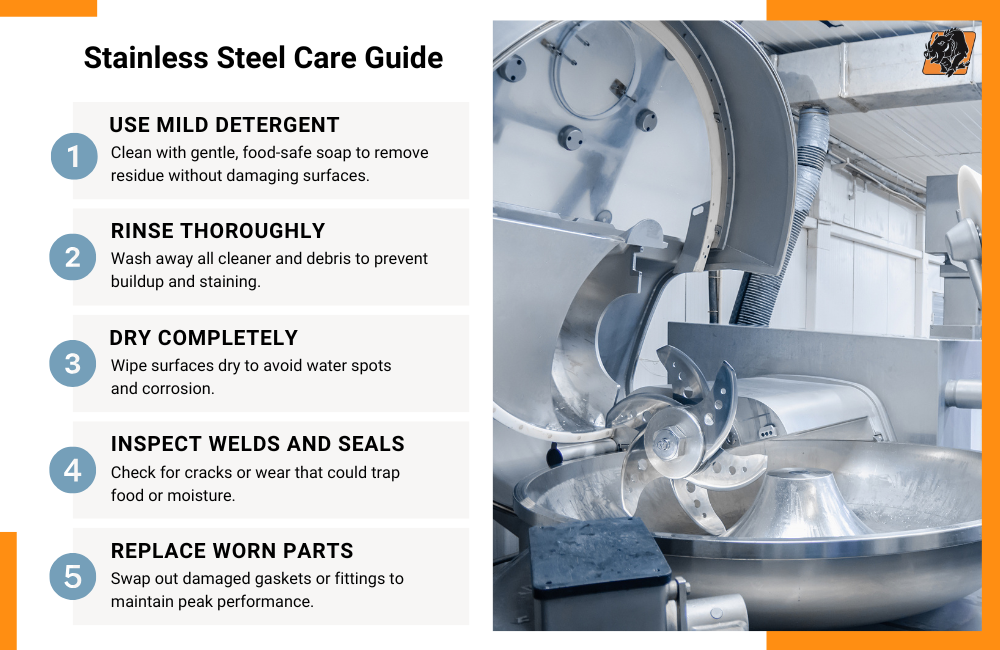

How Do I Maintain Stainless Steel Processing Equipment?

Proper maintenance keeps equipment in top condition and reduces downtime. Stainless steel is strong and sanitary, but it still requires regular care to avoid corrosion or damage.

Maintenance Best Practices:

- Clean with mild detergents and avoid harsh chlorine-based chemicals.

- Rinse thoroughly and dry to prevent spotting or rust.

- Inspect welds, seals, and machine parts frequently.

- Replace worn replacement parts promptly to maintain performance.

EZG Manufacturing builds equipment with modular access points, reducing service time and allowing quick component swaps. Well-maintained machinery sustains production capacity and supports consistent output without costly interruptions.

Equipment Efficiency and Throughput

How Can I Improve Efficiency in My Food Production Line?

Efficiency is about doing more with less: fewer manual steps, faster cycles, and minimal downtime. Modern machinery integrates automation, sensors, and precision controls to achieve consistent performance.

| Factor | Manual Operation | Automated Line |

|---|---|---|

| Labor Hours | Higher | Lower |

| Output Consistency | Variable | Steady |

| Maintenance Needs | Frequent | Predictable |

| Energy Use | High | Optimized |

By adopting the latest technology, such as smart conveyors or automated batching systems, food processors can achieve measurable gains in output and consistency.

For instance, a food manufacturer producing both baked goods and fried food products might integrate automated cooking equipment to maintain consistent results across different food categories.

EZG Manufacturing’s innovative solutions focus on improving efficiency without overcomplicating operations, giving processors the reliability and throughput they need for long-term success.

Safety and Compliance

Safety extends beyond operator protection. It’s also about maintaining product integrity and meeting regulatory standards. Food processing equipment must align with OSHA, FDA, and FSMA requirements to maintain safe operations and meet quality standards.

Built-in safeguards include:

- Locking panels and access guards

- Automatic shutdown sensors

- Emergency stop switches

- Interlocks that prevent operation during cleaning

Every EZG system is engineered to help facilities uphold strict food safety standards while protecting operators and maintaining full compliance. From design to delivery, safety is built into every step.

Scalability and Future Growth

Facilities grow, products evolve, and lines expand. This means your equipment should grow with your food business. Scalable systems are designed for single line operations or large scale production, depending on your needs. Modular equipment allows you to increase production capacity or adapt your layout for new food categories without major redesigns.

Example: a processor adding a new packaging equipment unit or conveyor system can easily integrate it into their existing setup, maintaining flow and consistency across the entire plant.

Total Cost of Ownership

Evaluating cost means more than just comparing price tags. The total cost of ownership includes maintenance, reliability, and uptime over the life of the system.

| Factor | Low-Cost Option | High-Quality Equipment |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance | Frequent | Predictable |

| Downtime | Common | Minimal |

| Lifespan | 3–5 years | 10+ years |

| ROI | Moderate | Strong |

High-quality, high performance equipment lasts longer, reduces unplanned outages, and improves quality control. Over time, durable systems save money and keep your finished products consistent. That’s a major advantage for any processor focused on growth.

Matching Equipment to Your Process

Every production line has different needs. Choosing the right equipment company means working with experts who understand both your process and your products.

Follow these steps when evaluating your setup:

- Map your food preparation and packaging stages.

- Identify where bottlenecks occur or where automation can help.

- Consider sanitation needs at each step.

- Match machine features to your specific application and volume goals.

Working with EZG means gaining a partner who understands different food categories, system integration, and the small details that make a big difference in daily production.

Why Partner with EZG Manufacturing

As a trusted equipment manufacturer, EZG Manufacturing applies decades of fabrication and engineering experience to the food processing industry. From material handling and mixing to packaging and automation, every system is designed to deliver measurable improvements in performance and reliability.

From concept to installation, EZG works closely with clients to create innovative solutions that strengthen food safety, simplify operations, and support long-term growth.

Contact EZG Manufacturing to discuss your next project, from a single system upgrade to a full-scale plant configuration.