What Is a Lathe?

A lathe is a machine tool designed to rotate a workpiece against a cutting tool. This process removes excess material to create the desired shape, typically cylindrical. Unlike milling, where the tool rotates, a lathe spins the material while the cutting tool stays fixed or moves along a programmed path.

The purpose of this operation is to create shapes such as rods, shafts, bushings, and threaded components. Lathes are found in machine shops worldwide, and they’ve played an important role in manufacturing for centuries.

There are different types of lathes:

- Manual lathes: Operated by hand, suited for simple jobs.

- Turret lathes: Ideal for repetitive work, featuring multiple cutting tools.

- Vertical lathes: Used for large, heavy parts.

- CNC lathes: Computer-controlled for precision and repeatability.

You may also hear about wood lathes for crafting bowls or decorative items. While those serve independent artists, industrial lathes focus on metals, plastics, and specialty alloys.

A Brief History of the Lathe

The lathe is often called the “mother of machine tools,” with roots tracing back thousands of years. Its biggest leap came during the Industrial Revolution, when early engine lathes were used to craft parts for steam engines, fueling advances in transportation and mass production.

As time went on, manual lathes powered by hand evolved into machines driven by electric motors. The 20th century introduced turret lathes for higher-volume production, and eventually, CNC lathes brought automation and digital precision to the process. Today, the lathe remains one of the most adaptable tools in any machine shop.

How Does a CNC Lathe Work?

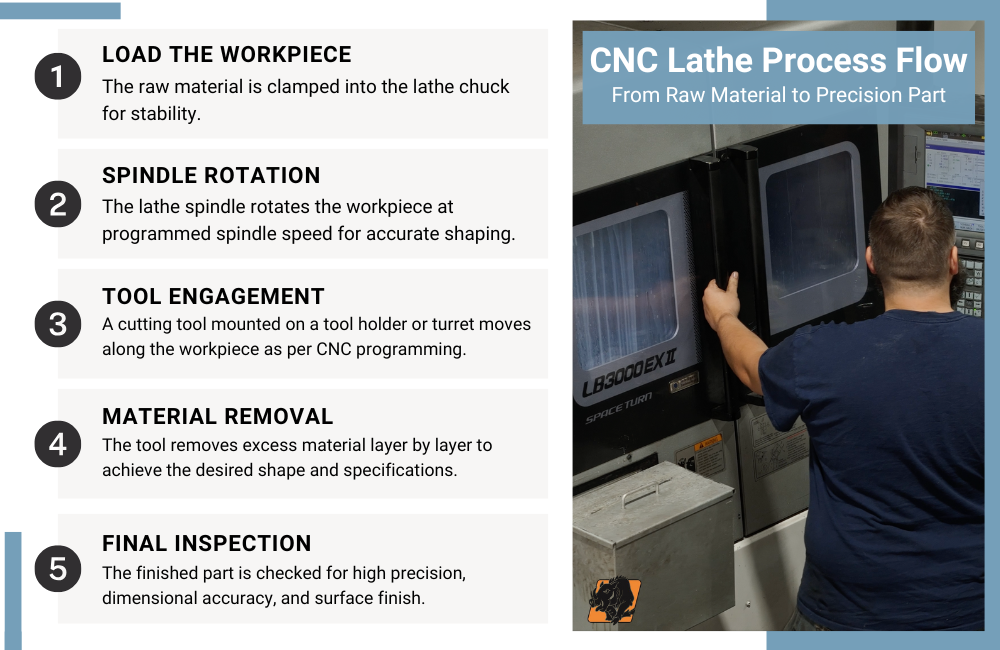

A CNC lathe uses computer numerical control to automate the turning process. Instead of an operator manually moving the tool, a programmed set of instructions directs every movement. Here’s how it works:

- The setup: The workpiece is mounted to the lathe chuck, a clamping device that holds it securely. Depending on the design, this might be a jaw chuck, screw chuck, or drill chuck.

- Rotation begins: The lathe spindle rotates the workpiece at a programmed spindle speed or rotational speed.

- Tool engagement: A cutting tool mounted on a tool holder moves along the workpiece. In advanced setups, multiple tools are held in a turret for quick changes.

- Material removal: As the workpiece spins, the tool removes material to create the required cylindrical shape or more complex parts.

- Finishing operations: Additional tools like a lathe reamer or drill bit can refine surfaces or drill precise holes.

The process runs at high speed, and adjustments can be made for feed rate, depth of cut, and finish requirements. For jobs requiring extra flexibility, machines with a Y axis can perform off-center drilling or milling.

CNC Lathe Components and Setup

Every CNC lathe is built around a few main components that make the process possible:

- Lathe Spindle: The rotating axis that powers the workpiece.

- Chuck Systems: Includes jaw chuck, screw chuck, and drill chuck for holding parts securely.

- Tool Holder and Turret: Where cutting tools are mounted; the turret allows quick tool changes during production.

- Cross Slide: Enables precise tool movement across the rotating part.

- Power Source and Electric Motor: Provides consistent energy for rotation and automation.

- Phase Converter: Converts power for machines running on three-phase electricity in smaller shops.

These parts work together to produce high precision results on everything from short runs to continuous production.

What Materials Can a CNC Lathe Handle?

One of the reasons CNC lathes are popular is their ability to handle a wide variety of materials. Common options include, stainless steel, carbon steel, aluminum, specialty and exotic alloys, and plastics for specific applications.

Some setups even work with sheet metal or non-metal components for specialized parts. The versatility of a CNC lathe makes it an excellent fit for industries requiring durability and reliability. At EZG Manufacturing, we work with sheet metal and a range of metal materials to shape them into the exact components your project requires.

Types of CNC Lathes

CNC lathes come in multiple designs suited to different applications:

- Vertical Lathe: Orients the workpiece vertically, useful for large-diameter components.

- Turret Lathe: Uses multiple tools mounted in a rotating turret for fast tool changes.

- Flat-Bed CNC Lathes: Great for handling long workpieces.

- Multi-Axis Machines: Add flexibility for complex geometries.

Smaller manual lathes still have a place in hobby shops or for independent artists, but for high-volume work, CNC reigns supreme.

Common Applications of CNC Lathe Work

CNC lathes play an important role in industries that demand accuracy and speed. Some examples include:

- Oil & Gas: Pressure-resistant components such as flanges and fittings.

- Food Processing: Sanitary-grade hardware and threaded fittings.

- Construction Equipment: Heavy-duty shafts, bushings, and couplings.

- Material Handling & Infrastructure: Large parts built for durability.

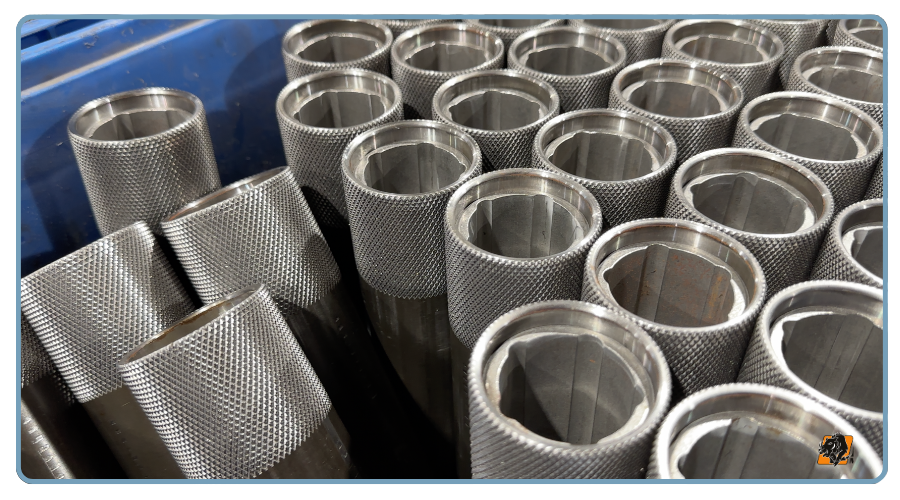

Common products created through lathe work include:

- Shafts and rods

- Threaded components

- Bushings and sleeves

- Custom cylindrical parts

Why CNC Lathes Are Preferred Over Manual Lathes

Why do manufacturers choose CNC lathes? The answer comes down to three main advantages:

- Accuracy: Automated movements allow for high precision every time.

- Speed: CNC programs cut down on setup time and allow continuous production.

- Complexity: These machines create parts that would be time-consuming or nearly impossible on a manual lathe.

From small machine shops to large-scale operations, CNC lathes have become the standard for modern manufacturing.

EZG Manufacturing: CNC Turning Services

At EZG Manufacturing, CNC turning is part of our full-service approach to custom fabrication. Our advanced CNC turning equipment includes the Clausing MultiTurn 2000 Turning Center, designed for precision and efficiency. Features include:

- 8-tool turret for multiple operations in one cycle

- Spindle speeds up to ~2700 RPM

- Workpiece capacity up to 14″ diameter and 46″ length

- Tolerances down to ±0.005″

- Magazine bar feeder for continuous runs

We work with stainless steel, carbon steel, aluminum, and specialty alloys. From prototypes to full-scale production, EZG delivers lathe work that meets your specifications.

Because we also offer CNC milling, fabrication, welding, powder coating, and finishing in-house, you get a fully integrated solution from start to finish. Our experienced machinists and engineers handle everything under one roof, saving time and reducing risk of delays.

Ready to bring your next turning project to life? Contact EZG Manufacturing today to discuss your requirements. Our team is here to deliver precision parts that fit your needs, on time and on spec.