Your heavy machinery represents one of the largest investments in your contracting business. A single excavator, loader, or mixer can cost tens of thousands of dollars. However, the real expense comes from how you maintain and protect that equipment over its working life.

Improper storage leads to rust, corrosion, dead batteries, cracked seals, and degraded hydraulics. It invites theft and vandalism. It accelerates depreciation and shortens the lifespan of machines you depend on. The good news? Most of these problems are preventable with the right heavy machinery storage practices.

Why Proper Heavy Machinery Storage Matters

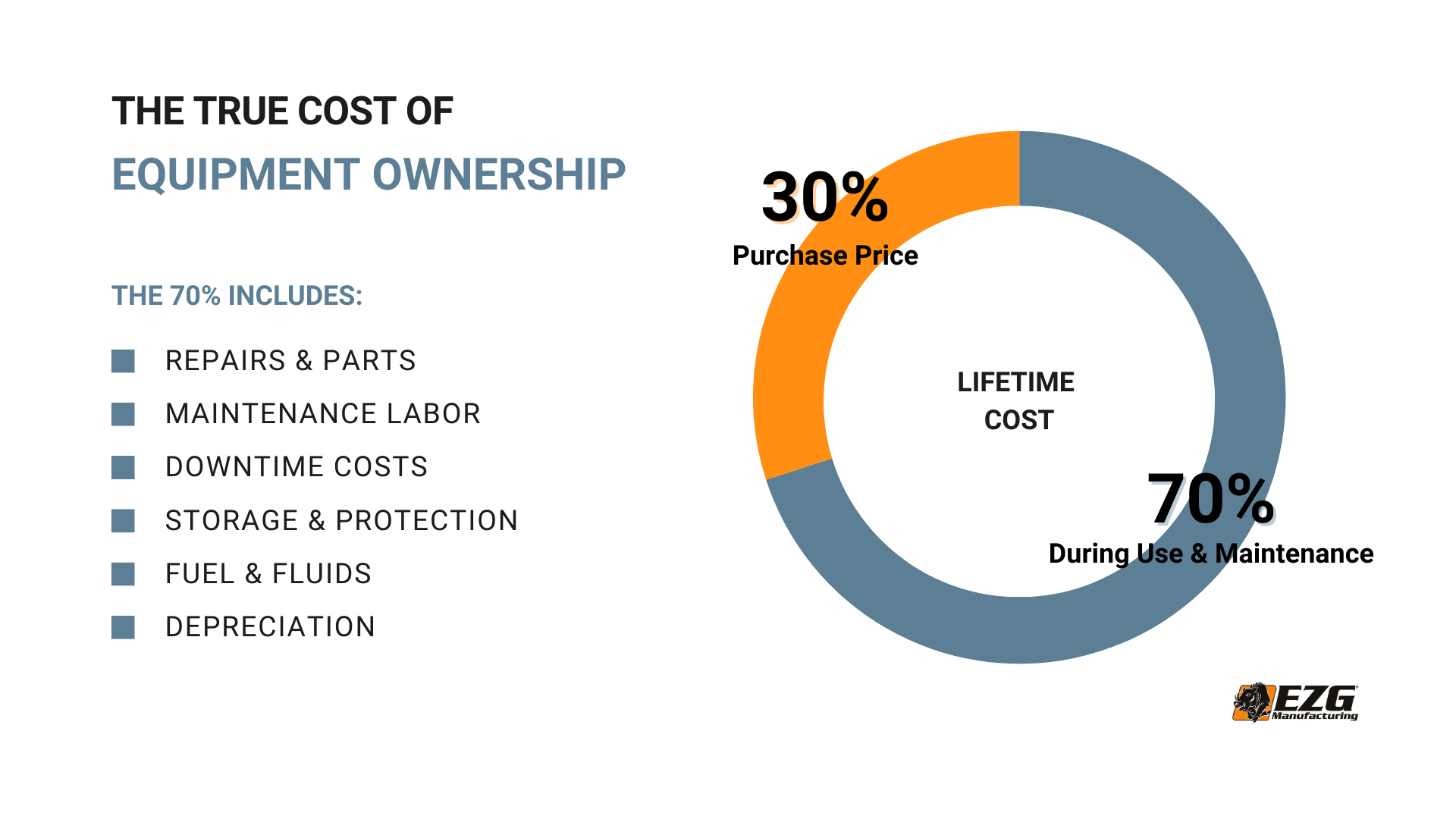

Here’s a number most contractors don’t think about: only 30% of your equipment costs happen at purchase. The other 70% comes from maintenance, repairs, downtime, and eventual replacement over the machine’s lifespan.

That math changes dramatically based on how you store your heavy equipment. A loader left exposed to rain, snow, and UV rays will need more frequent repairs than one kept under cover. Hydraulic seals dry out and crack. Electrical connections corrode. Rust eats through unprotected metal surfaces. Every breakdown means mechanics, parts, and, worst of all, job site delays that cost you money and reputation.

Weather damage isn’t the only concern. Unprotected equipment storage makes your machinery an easy target for theft. According to the National Equipment Register, construction equipment theft costs the industry up to $1 billion annually. Most stolen equipment is never recovered.

Poor storage also tanks resale value. When it’s time to upgrade or sell, buyers can spot neglected machinery immediately. That visible wear translates directly into lower offers and harder negotiations.

The bottom line: investing in proper storage protects your valuable asset and pays dividends throughout the equipment’s working life.

Storage Options for Heavy Equipment

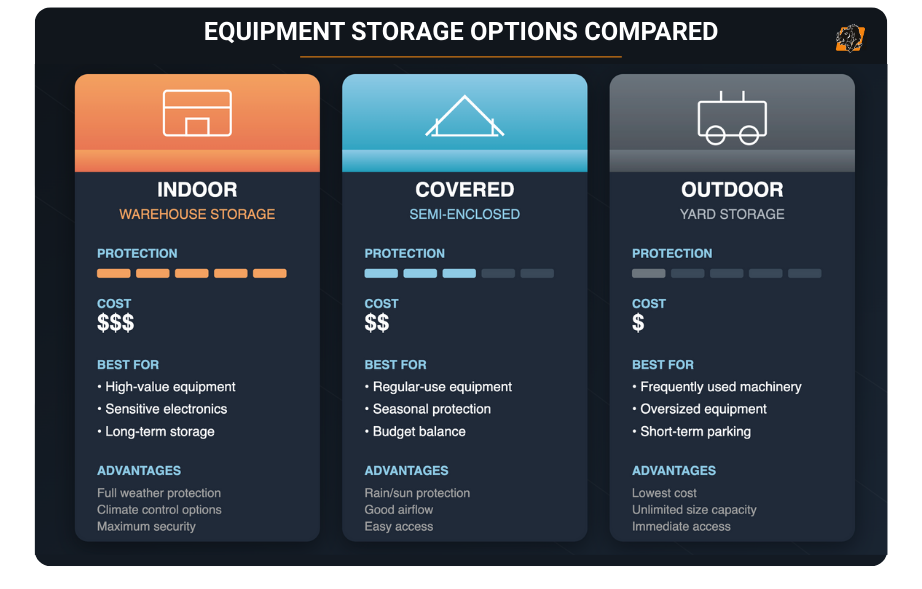

Choosing the right storage solution depends on your budget, available space, climate, and how frequently you use each piece of machinery. Here’s what to consider for each option.

Indoor Storage

Indoor storage offers the highest level of protection for your heavy machinery. A fully enclosed warehouse space shields equipment from rain, snow, ice, UV exposure, and temperature extremes. Climate control options can further protect sensitive electronics and hydraulic systems from humidity and condensation.

Beyond weather protection, indoor storage provides better security. Solid walls, locked doors, and controlled entry points make unauthorized access much harder than open outdoor areas.

The trade-off is cost. Warehouse space comes at a premium, especially for large equipment that takes up significant square footage. Indoor storage makes the most sense for high-value machines, equipment with sensitive electronics, or machinery going into long-term storage during off-seasons.

Outdoor Storage

Outdoor storage costs less and can accommodate oversized equipment that won’t fit through standard building doors. A well-designed storage yard provides easy access for moving machinery in and out quickly.

The challenge is protection. Without overhead cover, your equipment faces direct exposure to rain, snow, sun, and wind. Successful outdoor storage requires additional measures: quality tarps or fitted covers, concrete or gravel pads for drainage, and strategic positioning to minimize weather exposure.

Outdoor storage works best for equipment in regular rotation. These machines you use frequently enough that extended exposure isn’t a major concern. It’s also the practical choice for large machinery that simply won’t fit indoors.

Covered or Semi-Enclosed Storage

Covered storage offers a middle ground between full indoor protection and open outdoor storage. Options include pole barns, canopy structures, and three-sided shelters that block rain and direct sun while allowing airflow.

This approach protects against the most damaging weather exposure at a lower cost than full warehouse space. Many contractors find that covered outdoor storage facilities meet their specific needs without breaking the budget.

Storage Comparison

| Storage Type | Best For | Protection Level | Relative Cost | Access |

|---|---|---|---|---|

| Indoor/Warehouse | High-value equipment, sensitive electronics, long-term storage | Highest | $$$ | Requires scheduling |

| Covered/Semi-Enclosed | Regular-use equipment, seasonal protection | Moderate | $$ | Good |

| Outdoor with Covers | Frequently used machinery, oversized equipment | Basic | $ | Immediate |

| Open Outdoor | Short-term parking only | Minimal | $ | Immediate |

Seasonal Storage Considerations

Preparing Equipment for Winter Storage

Cold weather requires extra attention before putting machinery away for extended periods. Taking time to prepare equipment properly prevents costly problems when you’re ready to work again in spring.

Fluid maintenance tops the priority list. Change the oil and filters to remove contaminants that can cause corrosion during storage. Top off antifreeze to protect against freeze damage. Add fuel stabilizer to prevent gasoline from breaking down and gumming up fuel systems. For diesel equipment, fill tanks completely to minimize condensation.

Battery care prevents dead starts. Cold temperatures drain batteries faster, and a dead battery left too long can freeze and crack. Disconnect batteries and store them in a temperature-controlled area, or connect a battery maintainer to keep them charged throughout winter.

Tire and track maintenance avoids flat spots and cracking. Inflate tires to recommended pressure and consider blocking up equipment to take weight off tires during long-term storage. Inspect tracks for wear and proper tension.

Hydraulic system protection keeps seals and cylinders in working order. Retract hydraulic cylinders fully when possible. Apply a light coating of oil or protective spray to exposed cylinder rods to prevent pitting and corrosion.

Summer and Year-Round Maintenance

Winter isn’t the only season that threatens your equipment. Summer heat and UV exposure create their own problems.

Prolonged sun exposure fades paint, cracks rubber components, and can damage plastic housings and instrument panels. Use fitted covers or park machinery in shaded areas whenever possible. Light-colored covers reflect heat better than dark ones.

Dust and debris accumulate faster in dry summer conditions. Regular cleaning keeps air intakes and filters clear, preventing overheating and excessive engine wear. Pay attention to radiators and cooling fins that can become clogged.

For equipment stored in enclosed spaces during summer, ventilation matters. Heat buildup inside storage buildings can exceed outside temperatures significantly, accelerating wear on rubber and plastic components.

Security Measures for Your Equipment

A secure storage facility starts with controlled access. Fencing with locked gates limits entry points and deters casual thieves. The harder you make it to access your equipment, the less attractive a target it becomes.

On-equipment security adds another layer of protection. Wheel locks and steering locks prevent machinery from being driven away. Ignition disablers and hidden kill switches stop thieves who manage to get into the cab and even simple measures like removing keys and parking equipment strategically create obstacles.

Lighting matters too. Well-lit storage areas are less appealing to thieves who prefer to work unobserved. Motion-activated lights draw attention to after-hours activity.

Surveillance and Monitoring

Security cameras serve double duty: they deter theft and provide evidence if something does happen. Position cameras to cover entry points, high-value equipment, and blind spots in your storage yard.

GPS tracking has become increasingly affordable and offers peace of mind for your most valuable machinery. If equipment is stolen, GPS tracking dramatically improves recovery chances. Some systems also provide geofencing alerts if machinery moves outside designated areas.

Remote monitoring systems let you check on your facility from anywhere. Many integrate cameras, motion sensors, and alarms into smartphone apps that notify you immediately if something triggers the system.

Pre-Storage Preparation Checklist

A consistent pre-storage routine protects your investment and makes startup easier when you need the machine again.

Cleaning and Inspection

Start with a thorough wash. Remove all dirt, mud, concrete residue, and debris. Pay attention to undercarriages, wheel wells, and crevices where material accumulates. Caked-on mud holds moisture against metal surfaces and accelerates corrosion.

With the machine clean, inspect it carefully. Look for damage, leaks, worn parts, and any issues that need attention. Document the equipment’s condition with photos. This creates a record for maintenance tracking and provides proof of condition if you ever need to file an insurance claim.

Fluid and Mechanical Preparation

Change oil and filters before storage. Used oil contains acids and contaminants that can damage engine internals over time. Fresh oil provides better protection.

Grease all fittings and lubrication points. This forces out old grease and any moisture that may have worked into joints and bearings.

Check and top off all fluid levels: coolant, hydraulic fluid, transmission fluid, and fuel. Run the engine up to operating temperature before final shutdown. This circulates fresh fluids throughout the system and burns off any moisture in the engine.

Pre-Storage Checklist

| Task | Purpose | Priority |

|---|---|---|

| Wash and clean thoroughly | Prevent corrosion, enable inspection | High |

| Change oil and filters | Remove contaminants | High |

| Grease all fittings | Protect bearings and joints | High |

| Top off all fluids | Prevent condensation, protect seals | High |

| Add fuel stabilizer | Prevent fuel breakdown | High |

| Inspect for damage/wear | Identify needed repairs | Medium |

| Check tire/track condition | Prevent flat spots, cracking | Medium |

| Disconnect or maintain battery | Prevent dead battery, freezing | Medium |

| Apply protective coatings to exposed metal | Prevent rust | Medium |

| Document condition with photos | Maintenance records, insurance | Low |

Documentation

Update your maintenance logs with all work performed. Note any issues that need attention before the equipment goes back into service. Store manuals, registration documents, and maintenance records in an accessible location. You’ll need them eventually.

Protecting Specialized Equipment

Mixers and Material Handling Equipment

Mixers require special attention because of the materials they handle. Concrete, grout, and mortar will harden inside drums, paddles, and delivery systems if not cleaned promptly and thoroughly. What starts as a thin residue becomes a rock-hard layer that’s extremely difficult to remove.

After each use, flush systems with water until discharge runs clean. Before storage, inspect drum interiors, mixing paddles, and all contact surfaces for buildup. Clean connection points and hoses to prevent material from curing in place.

Industrial equipment that handles heavy loads needs inspection of structural components: welds, pivot points, and load-bearing surfaces. Look for cracks, bending, or signs of metal fatigue.

Lifting and Rigging Equipment

Cables, chains, slings, and attachment hardware demand careful storage. Inspect all components for wear, kinks, fraying, and corrosion before putting them away. Damaged rigging should be tagged and removed from service.

Store rigging equipment in dry conditions. Moisture promotes rust on chains and cables, weakening them invisibly. Proper coiling prevents kinks in cables that can create weak points. Hang chains rather than piling them to avoid tangles and stress points.

Keep lifting equipment organized and labeled. When you need specific rigging on a job site, you don’t want to waste time searching through a jumbled pile.

Equipment Built to Last: The EZG Manufacturing Advantage

Even the best storage habits can’t make up for equipment that’s poorly designed or cheaply built. Machinery that breaks down constantly or can’t handle real job site conditions will always cost you more in the long run, no matter how carefully you store it.

That’s the philosophy behind EZG Manufacturing. Founded by contractors who were tired of equipment failures and machines that couldn’t do what they needed, EZG builds equipment designed to work the way contractors actually work.

Durability is designed in from the start. Our company’s motor mixers, for example, use 3/8″ steel drums, thick enough that the biggest guy on the crew can’t put a dent in it with a sledgehammer. That’s the design standard.

EZG’s product line includes the Grout Hog® and Mud Hog® for masonry applications, the Fence Hog® line for fencing contractors, and custom fabrication services for specialized project needs. The goal is straightforward: equipment you can rely on, season after season, especially when paired with smart storage and maintenance practices.

If you want to see the full product line or compare options for your crew, you can browse the catalog or contact our team for help narrowing it down.