Material handling conveyor systems keep operations moving by transporting everything from small packaged goods to heavy raw materials. With such an important role in day-to-day productivity, they require regular attention to stay reliable.

Basics of Material Handling Conveyor Systems

At the simplest level, a conveyor system is a piece of equipment that moves materials from one point to another. Instead of relying on forklifts, carts, or manual labor, conveyors are engineered solutions that create a continuous flow, saving time and reducing strain on workers.

These systems can carry:

- Bulk materials like sand, stone, or concrete

- Precast or refractory components

- Packaged bulk goods and boxed products

- Pallets, equipment, or heavy loads

- Food or pharmaceutical products requiring hygienic handling

By design, conveyor systems reduce the effort needed to move products through a facility or across a jobsite. They become the backbone of material handling in industries where efficiency and consistency matter.

Understanding Material Handling Conveyor Systems

Material handling systems vary by design, application, and load requirements. Each type has its own maintenance priorities, but they all share the need for ongoing care.

Common Types of Conveyors

| Conveyor Type | Common Applications | Maintenance Priority |

|---|---|---|

| Belt Conveyors | Manufacturing, packaging, bulk | Belt condition, alignment, drive |

| Roller Conveyors | Warehousing, logistics | Bearing checks, roller wear |

| Food-Grade Conveyors | Food processing, pharma | Hygiene, belt sanitation |

| Heavy-Duty Conveyors | Mining, precast, refractory | Structural integrity, shafts |

Belt conveyors dominate many facilities because of their flexibility and ability to handle different materials. Roller conveyors are frequent in logistics centers. Food-grade conveyors follow sanitation standards that require strict cleaning routines. Heavy-duty conveyors, often used in precast and refractory work, must withstand tough environments and heavy loads.

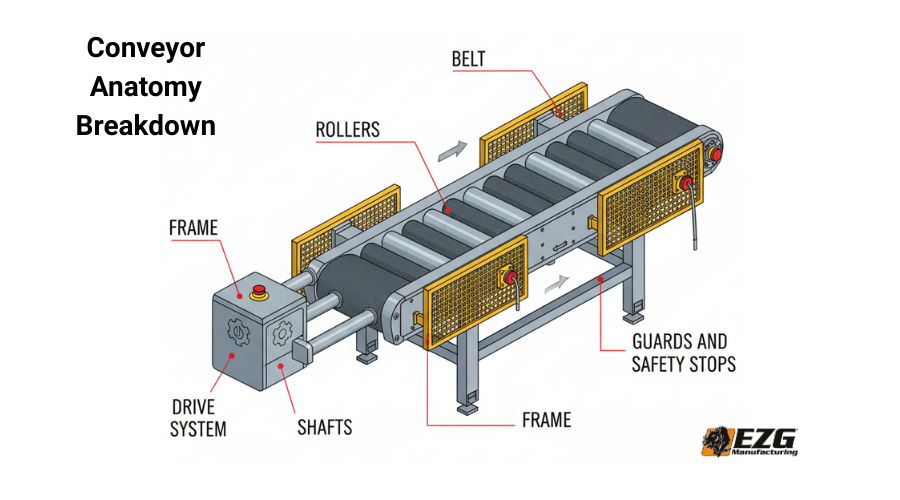

What Conveyor Systems Are Typically Made From

Conveyor systems use frames, belts or rollers, and drive components, with the right material chosen for the load and environment. Frames may be carbon steel, stainless steel, or aluminum, while belts range from rubber and PVC to metal mesh. Rollers and shafts are typically steel or aluminum, and food-grade conveyors often use stainless steel or plastic composites. Using the right material supports durability, keeps assembly lines moving, and strengthens the production process.

Why Conveyor Maintenance Matters

Neglecting conveyor belt maintenance can affect equipment, productivity, employee safety, and bottom-line costs. Here’s why regular upkeep is so important:

- Prevent downtime – Regular checks reduce the risk of sudden breakdowns that halt production.

- Extend lifespan – Equipment that’s maintained properly lasts longer, reducing replacement costs.

- Protect workers – A well-kept system lowers the chance of accidents caused by faulty parts.

- Support consistent output – Maintenance avoids interruptions that disrupt production schedules.

- Lower repair costs – Small issues caught early are usually cheaper to fix than major failures.

Routine Conveyor Maintenance Tips

1. Visual Inspections

During daily walk-throughs, look for worn belts, misaligned rollers, or loose fasteners. Pay attention to signs of dust buildup, oil leaks, or product debris that could affect system performance. Also check belt tracking, since a drifting belt often indicates that adjustments are needed.

2. Belt and Roller Care

Start by inspecting belt tension, since belts that are too tight place stress on the drive system while those that are too loose can slip. Replace any belts showing signs of fraying, cracking, or stretching. Keep rollers and bearings lubricated according to manufacturer guidelines, and confirm that rollers rotate freely, as resistance often points to dirt buildup or a lack of lubrication.

3. Cleaning Practices

Regular cleaning helps prevent buildup that can cause premature wear. For food-grade conveyors, it’s important to follow sanitation protocols that use approved cleaning agents and rinse cycles. Grease and product spills should be removed quickly before they spread along the line, and pulleys, drives, and rollers should always be kept free of residue.

4. Motor and Drive Systems

Listen for unusual sounds from motors, as grinding, squealing, or knocking often signal problems. During operation, check for overheating and watch for changes in performance. Inspect drive chains, pulleys, and shafts to confirm proper alignment and check for wear. Apply lubrication on the recommended schedule, taking care to avoid both under- and over-lubrication.

5. Safety Checks

Confirm that all guards and covers are securely in place, and test emergency stops at regular intervals to make sure they function as intended.

Preventive Maintenance Scheduling

A structured preventative maintenance program makes upkeep predictable and manageable. Assigning daily, weekly, monthly, and annual tasks helps catch small issues before they become large ones.

Example Preventive Maintenance Schedule

| Frequency | Tasks |

|---|---|

| Daily | Visual checks, belt tracking, clear debris |

| Weekly | Lubricate bearings, inspect belt wear, tighten hardware |

| Monthly | Motor alignment, drive system inspection |

| Quarterly | Structural checks, safety device testing |

| Annual | Full system audit, replace worn components |

Common Issues and How to Address Them

Even with good upkeep, conveyors may face issues over time. Recognizing them early helps keep operations on track.

Belt Misalignment

- Cause: Uneven loads, damaged pulleys, or poor tracking setup.

- Fix: Adjust tension and tracking; replace pulleys if worn.

Roller or Bearing Failure

- Cause: Lack of lubrication or contamination from dust or debris.

- Fix: Replace faulty rollers, keep spares on hand, and follow lubrication schedules.

Motor Overheating

- Cause: Overloading, blocked airflow, or excessive belt tension.

- Fix: Reduce load, clean motor vents, check drive alignment.

Material Buildup

- Cause: Irregular cleaning or unsuitable cleaning methods.

- Fix: Establish cleaning routines, use proper agents, and assign responsibility.

Training and Documentation

Conveyor lines perform best when the entire team understands how to operate and maintain them. Training gives staff the ability to spot early warning signs such as belt drift, unusual noise, or overheating. A maintenance logbook creates a clear record of inspections, lubrication dates, and part replacements, while simple daily or weekly checklists build accountability and help prevent important steps from being overlooked.

When to Call for Professional Support

Not all conveyor issues can be solved in-house. Some situations require expert support or even system redesign.

- Persistent tracking issues – If belts repeatedly drift despite adjustments.

- Frequent roller failures – Indicates deeper alignment or loading issues.

- System overloads – When conveyors can’t handle the current material flow.

- Major structural wear – Cracks or deformation in frames or supports.

Working with a manufacturer that understands conveyor design and fabrication allows companies to resolve deeper challenges and even customize new systems for better performance.

EZG Manufacturing: Material Handling Solutions That Carry Their Weight

At EZG Manufacturing, we manufacture custom material handling conveyor systems that are ready for tough jobs and frequent use. Our custom conveyor solutions move more than just materials — they move productivity forward.

Our Capabilities Include:

- Custom Conveyor Systems – Built for unique loads, layouts, and production goals.

- Precision Shafts and Components – Fabricated for smooth operation and minimal downtime.

- Custom Docks and Loading Solutions – Support logistics inside and outside the manufacturing facility.

- Bulk Material Transport Systems – Move large volumes with consistency and reliability.

- Food-Grade Conveyor Belts – Built to meet hygiene standards and withstand constant use.

- Fabrication Services – From welding and machining to full system assembly, our in-house fabrication services allow us to deliver conveyors and components that fit your exact needs.

Since 1998, EZG has supplied material handling solutions that last. Backed by decades of experience in fabrication services, we provide conveyor systems and components that reduce downtime, support steady output, and match the demands of your production process.

Contact EZG Manufacturing today to discuss how our conveyor systems and fabrication services can support your material handling needs.