A skid steer will always be one of the most versatile machines you bring to a jobsite. It lifts, carries, transports, grades, and powers your day from start to finish. But the real production gains – the kind that save labor, increase daily output, and let small crews work like large ones – come from the attachments you run.

The right skid steer attachment can replace a standalone machine, eliminate hours of manual labor, and widen the type of work your crew can confidently take on. This guide covers the most valuable skid steer attachments for masonry, fencing, concrete, demolition, and general contracting, with real-world examples from EZG Manufacturing, a leader in contractor-grade equipment.

Why Skid Steer Attachments Matter

A skid steer is only earning money when it’s working, not when it’s waiting between tasks. Skid steer attachments flip that role. Attachments turn the machine into a production tool capable of running continuously through a job rather than waiting for isolated moments of use.

A good attachment should do at least one of these things:

- Eliminates repetitive manual labor

- Replaces the need for additional machines or rentals

- Lets you take on work you couldn’t handle before

If an attachment doesn’t accomplish any of these, it probably isn’t worth the investment.

Before choosing, think about your hydraulic flow, ground conditions, lift specs, and how often you’ll rely on the attachment. From there, the best way to choose is by looking at the trade-specific bottlenecks you deal with every day.

Which Attachments Are Best for Your Trade?

Not every attachment fits every contractor. Below is a breakdown by trade so you can jump to what applies to your work.

Masonry Contractors

Masonry projects usually rise or fall based on how well mixing keeps up with production. Long block runs, heavy material handling, and large waste piles all make the day slower and more physically taxing.

Common bottlenecks:

- Bucketing or wheelbarrowing mortar long distances

- Mixers that can’t keep up with wall progress

- Block, brick, or demo waste piling up

Attachments that deliver on-demand batches, reduce manual hauling, and turn waste into usable backfill have the biggest impact for masons.

Fencing Contractors

Fence installation is one of the most physically exhausting trades. Rolling out chain link by hand, fighting tangled field fence, carrying barbwire, and running miles of footers (all by hand) crushes production.

Fencers benefit most from attachments that:

- Attachments that carry and unroll wire

- Controlled tensioning systems

- Accurate concrete placement along fence lines

- Post-hole drilling without manual digging

- Better productivity with smaller crews

When combined, these attachments turn a grueling workflow into a steady, repeatable process.

Concrete Contractors

Concrete work doesn’t wait. When mixing slows down, every part of the schedule falls behind.

Concrete-focused attachments support crews’ productivity by:

- Providing consistent on-site batches

- Moving material long distances or into tight spaces

- Reducing the strain of wheelbarrow work

- Ensuring cleaner, more accurate pours

The result is a more predictable pour and a crew that stays fresher throughout the day.

General Contractors & Site Prep

GCs need flexibility. One hour you’re breaking up old slab, the next you’re cleaning debris or moving pallets of block.

These crews gain the most from attachments that handle:

- Demolition

- Material handling

- Ground prep

- Cleanup

- Utility digging

A skid steer equipped with the right essentials becomes the anchor tool of the jobsite. The attachments keep production flowing all day, not just part of the day.

Best Skid Steer Attachments to Increase Jobsite Production

Below are the top attachment categories. Each section includes EZG options as well as other attachment types contractors rely on every day.

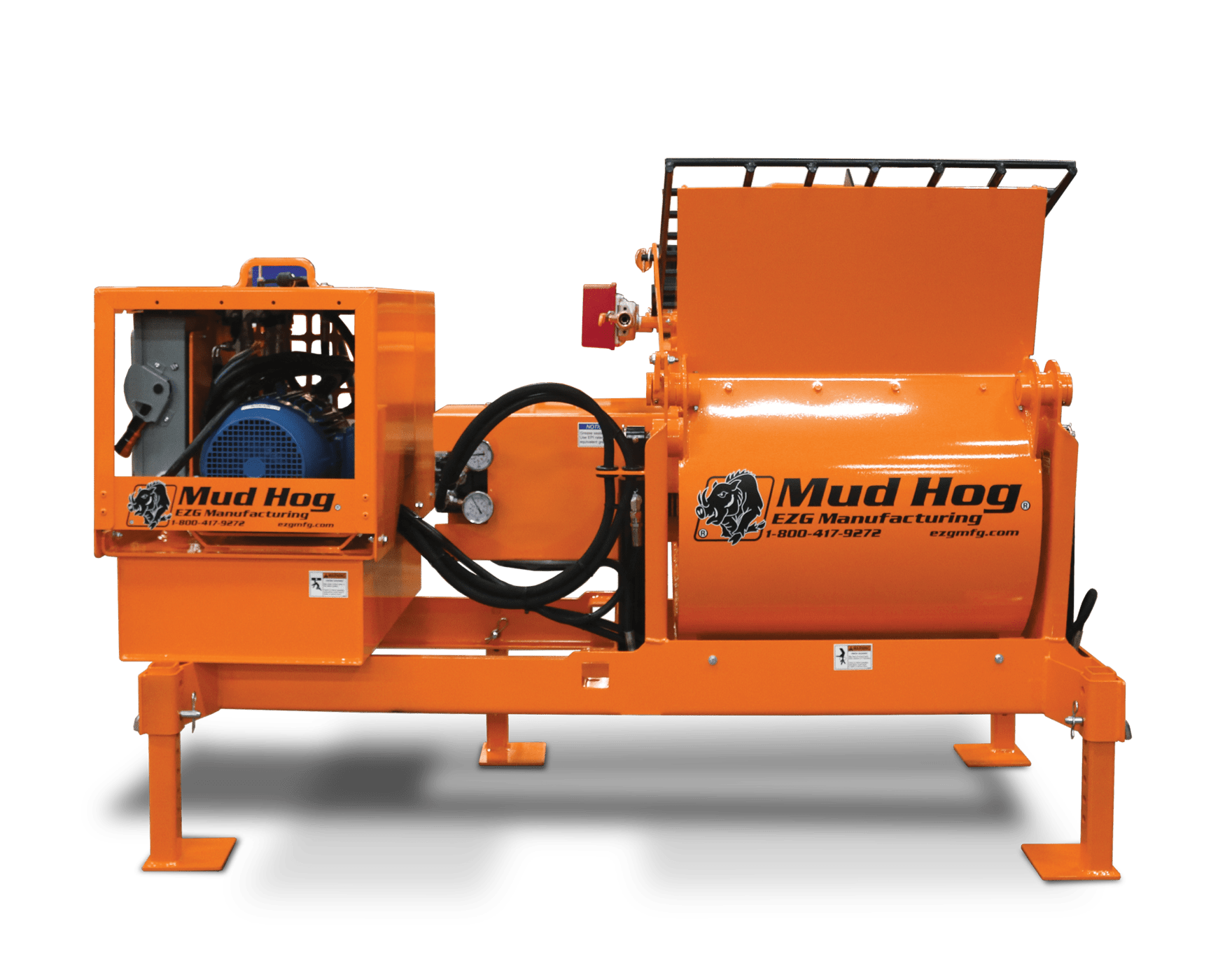

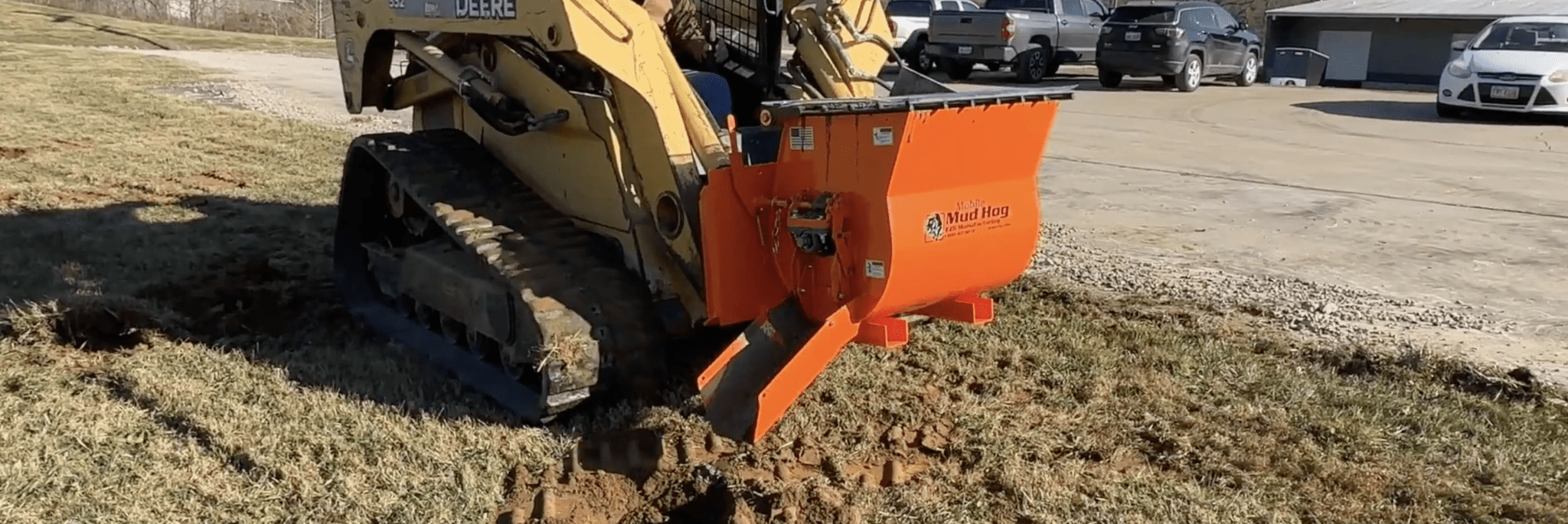

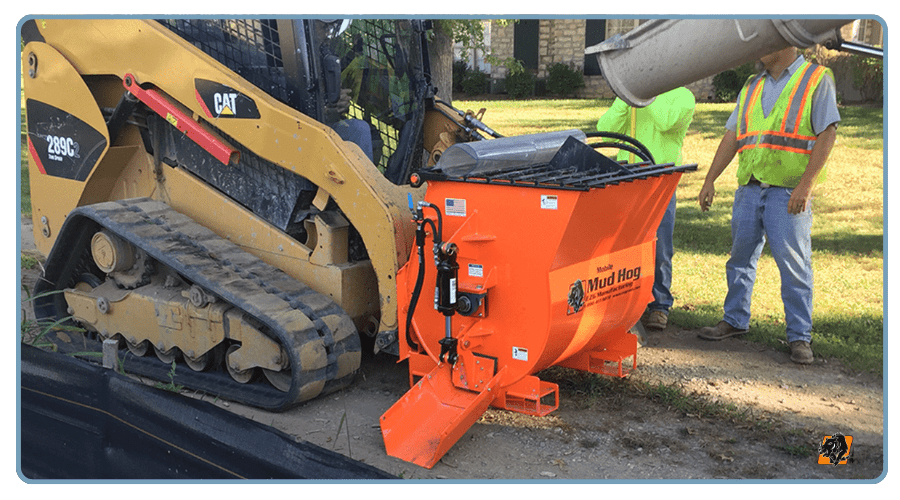

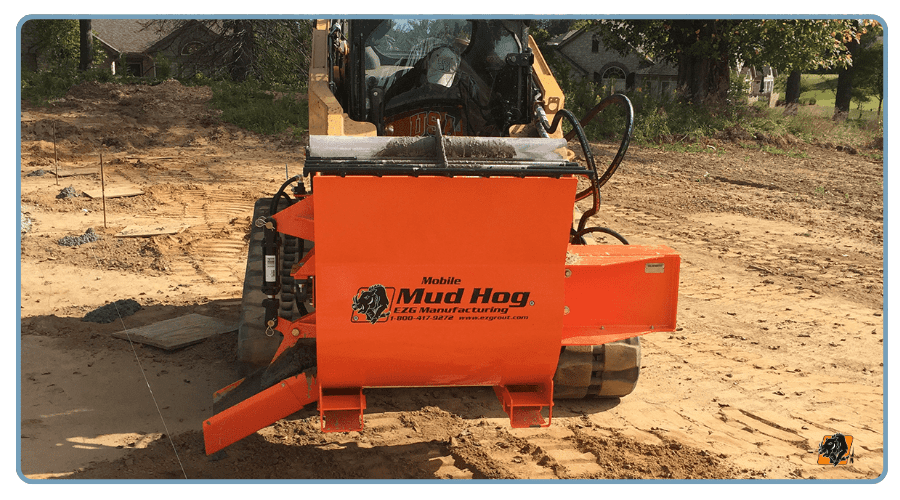

1. EZG Mobile Mud Hog® Mixers — Faster Mixing, Less Labor, No Downtime

Masons and concrete crews know the pain of slow mixing, uneven batches, and wasted time hauling materials back and forth. Traditional tow-behind mixers slow production, especially when fence lines, spread-out footers, or remote locations make truck access impossible.

The Mobile Mud Hog® solves that problem by giving crews a skid steer-powered mixer that delivers consistent batches anywhere on the site. You load it with your skid steer, mix on demand, and dump exactly where you need it. Its patented paddle design pushes material through the mix instead of dragging it, so you get better blending in less time.

Contractor Benefits

- Consistent batches delivered anywhere on-site

- No reliance on cement trucks for small or remote pours

- Less fatigue from carrying buckets

- Better mix quality from the patented paddle system

- Handles mortar, grout, and concrete with up to ¾” aggregate

If your mixer causes even 20–30 minutes of downtime each day, this attachment pays for itself within a few months.

2. EZG Hog Crusher® Material Recycling System — Turn Waste Into Usable Aggregate

Waste piles slow crews down, eat up space, and drive up disposal runs. Many jobs end up paying to haul off broken block or concrete, then paying again to bring in new aggregate.

The Hog Crusher® changes that by turning leftover block, brick, and concrete debris into usable material on the spot. Instead of throwing waste into a dumpster, you crush it and reuse it for backfill, temporary access paths, or base material.

Use it to create:

- Backfill

- Base layers

- Temporary access paths

- Trench bedding

For anyone working demolition, masonry, hardscape, or utility work, this attachment turns trash into resources.

3. EZG Fence Hog® — Faster, Safer Chain Link Installation

Chain link installation is usually slow, inconsistent, and physically exhausting. Rolling out heavy fencing by hand and trying to maintain tension leads to uneven lines, poor alignment, and high labor costs. In large-scale industrial projects, these pain points multiply fast.

The Fence Hog® mounts directly to your skid steer or walk-behind and lets you carry, unroll, and position chain link with controlled tension. The optional tilt plate helps you stay level on uneven terrain, and the optional cage extensions let you handle taller fencing without awkward lifts.

Contractor Benefits

- Carry and unroll fencing with far less manual lifting

- Get straighter, tighter lines with consistent pull

- Reduce strain injuries caused by lifting heavy rolls

- Knock out long runs faster with a smaller crew

- Use the tilt plate to work cleanly on slopes and uneven ground

For contractors installing commercial security fencing, rural boundary fencing, or utility fencing, this attachment delivers fast production with lower labor fatigue. A 3-person crew can often install what normally takes 5–6 people, without burnout.

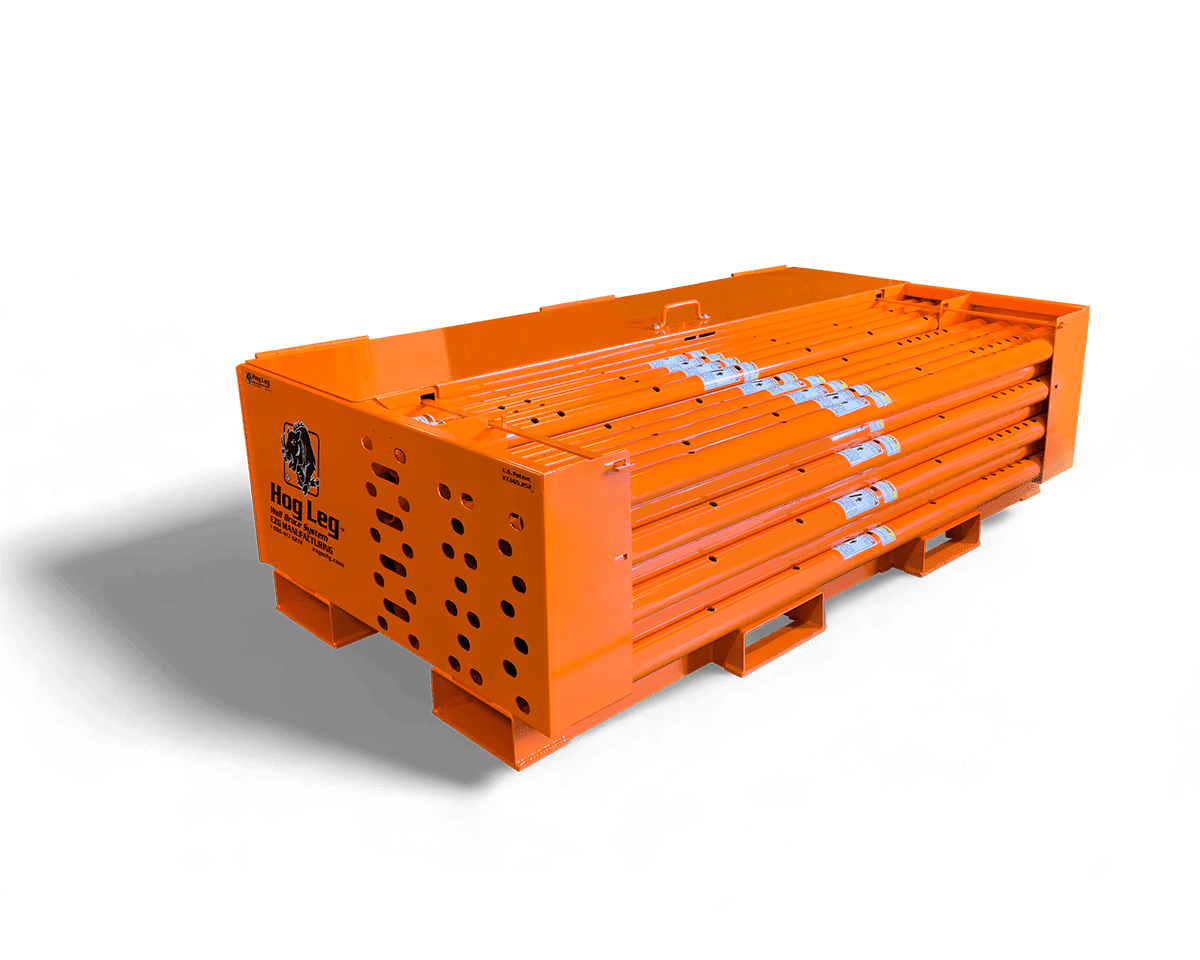

4. EZG Stretch-N-Go® Hog — Controlled Tensioning for Field Fence

Field fence is notoriously tough to manage. When pulled by hand or with improvised rigs, it kinks, snags, and fights you every step of the way. Uneven tension means sagging sections and unhappy customers.

The Stretch-N-Go® Hog loads directly with a skid steer and tensions the wire as it dispenses. You set the braking system to get reliable tension across the entire run. It handles multiple rolls at once depending on model choice, letting you run long distances without reloading.

Contractor Benefits

- Load large rolls with your skid steer, not your back

- Save time by running multiple rolls before reloading

- Great for agricultural, ranch, and rural fencing jobs

- Optional barbwire add-on for jobs that need extra security

For long rural fence lines or large farm jobs, nothing beats the consistency this attachment delivers.

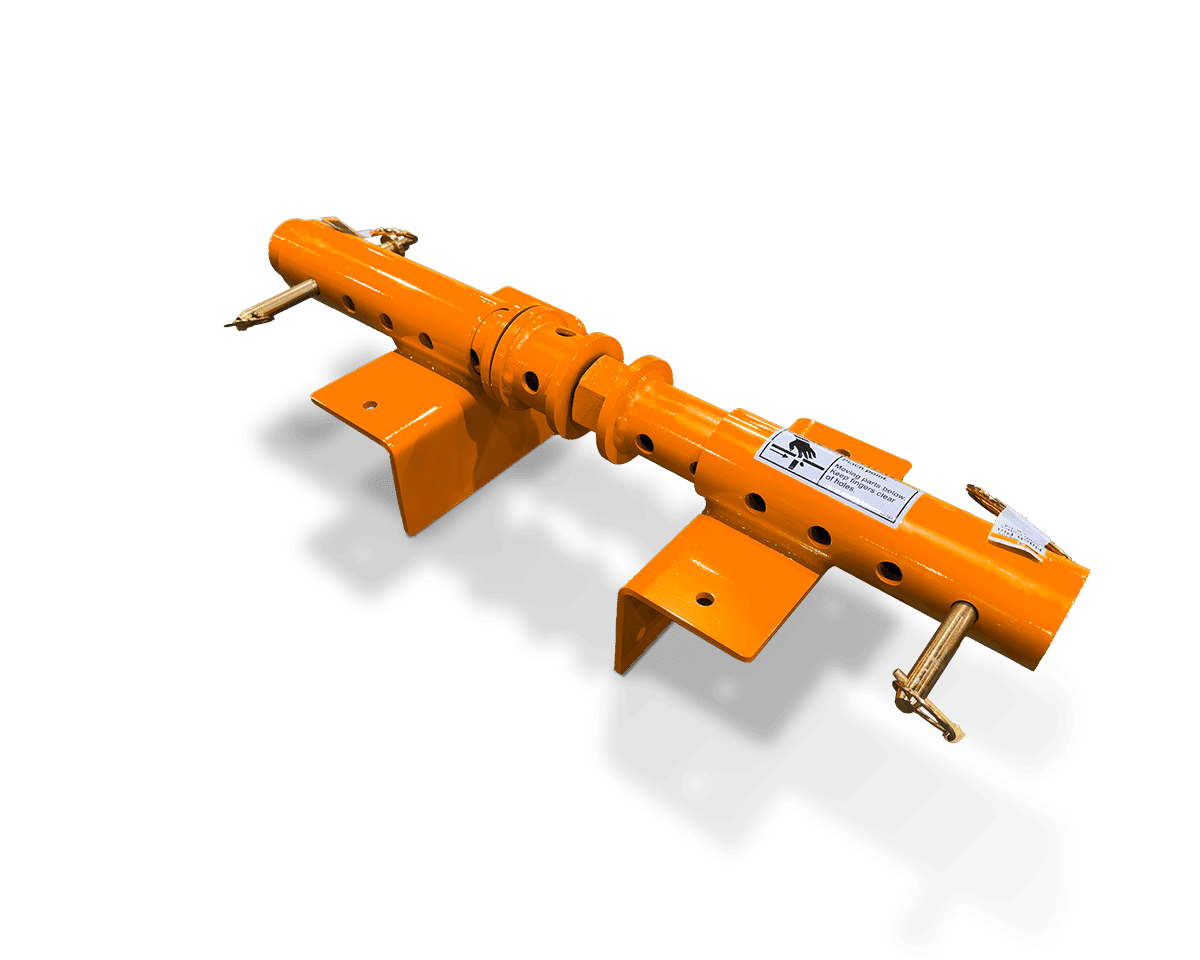

5. EZG Barbwire Hog® — Safer, Faster Barbwire Installation

Barbwire is one of the most dangerous materials to handle by hand. Crews struggle with cuts, snags, unpredictable tension, and rolls that get away from them. The Barbwire Hog® solves all of that with a pivoting, skid steer-mounted system that controls tension while keeping workers clear of sharp wire.

The hydraulic arm lets you feed wire on either side of the fence line, giving crews more control in tight or uneven areas. Optional tension wire attachments let you run top and bottom lines without swapping tools.

Contractor Benefits

- Drastically reduces the hands-on handling of sharp wire

- More controlled tension without sudden slips or snaps

- Pivoting arm helps navigate slopes, corners, and obstacles

- Handles multiple rolls depending on model

Contractors working in security fencing, livestock containment, and utility perimeters rely on it for a safer workflow.

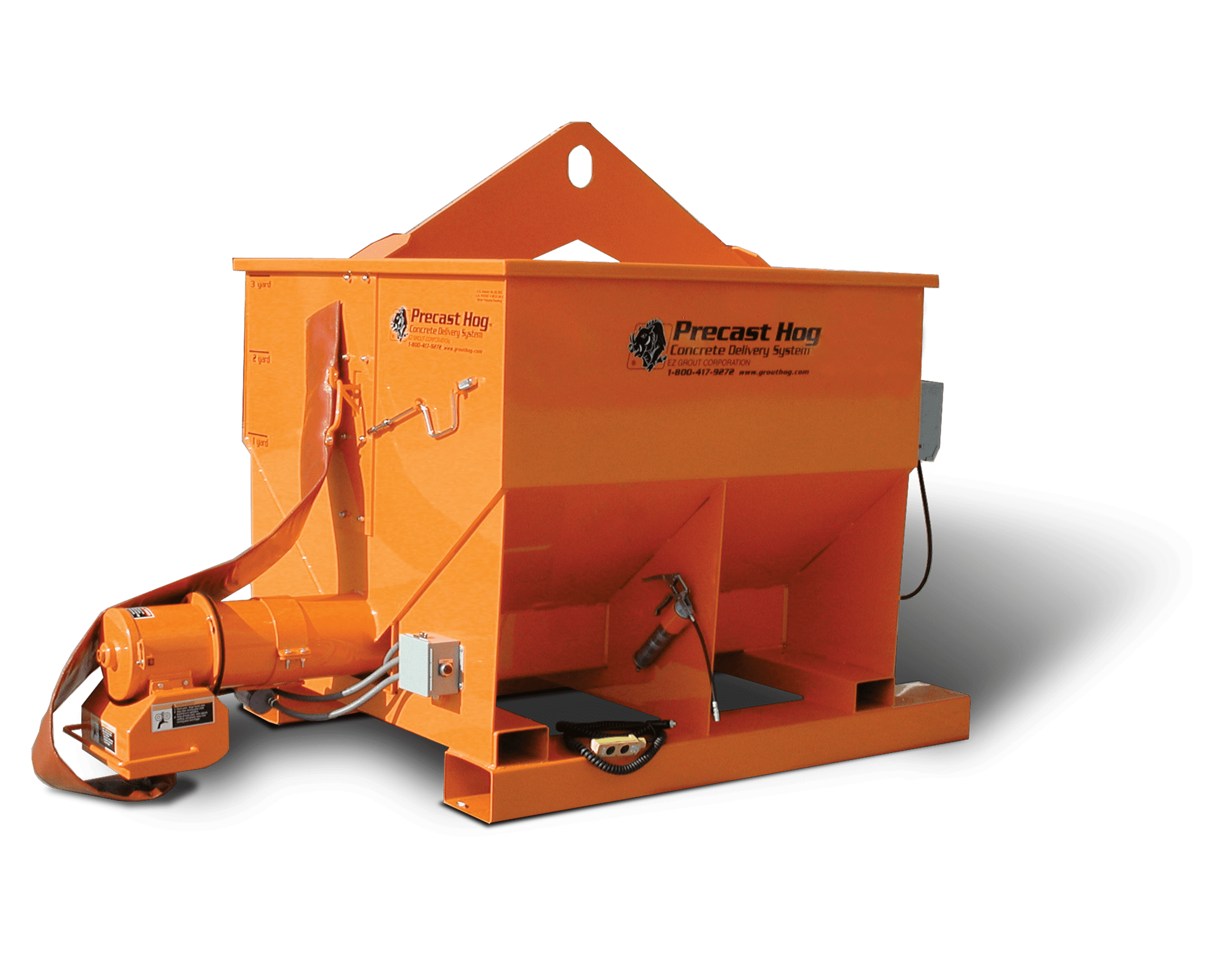

6. EZG Fencer’s Cement Hog® — Accurate Concrete Placement Along Fence Lines

Pouring concrete along miles of fence line is slow and frustrating. Buckets spill, wheelbarrows bog down in soft ground, and trucks often can’t get anywhere near the install area. The Fencer’s Cement Hog® solves the problem by letting you carry and dispense concrete or sand precisely along the fence line.

You load the hopper with a skid steer, drive along the fence, and release material exactly where you need it. The controlled flow cuts down on waste and keeps the crew moving at a steady pace.

Contractor Benefits

- Pour concrete along fence lines without wheelbarrows

- Perfect for long runs, tight spaces, and soft ground

- Cuts down on cleanup caused by sloppy pouring

- Pairs well with augers and wire stretchers for full fencing workflow

A go-to choice for ranch, farm, and large property fencing.

7. EZG Triple-Use Mobile Mixers — Heavy-Duty Skid Steer Mixing for Grout, Mortar & Concrete

These mixers are built for contractors who need a dependable mixing system that can support any stage of masonry or small-batch concrete work. With the ability to handle up to ¾” aggregate, plus a reversible paddle system and a manual gate for controlled dumping, these mixers give you strong output without stalling the crew.

Contractor Benefits

- Mix multiple material types with one attachment

- Hydraulic power delivers fast mixing without manual strain

- Reversible paddles help clean the tub and keep material moving

- Reliable loading and dumping setup for better material control

Perfect for small slabs, grout pours, block fill, wall construction, and repair work.

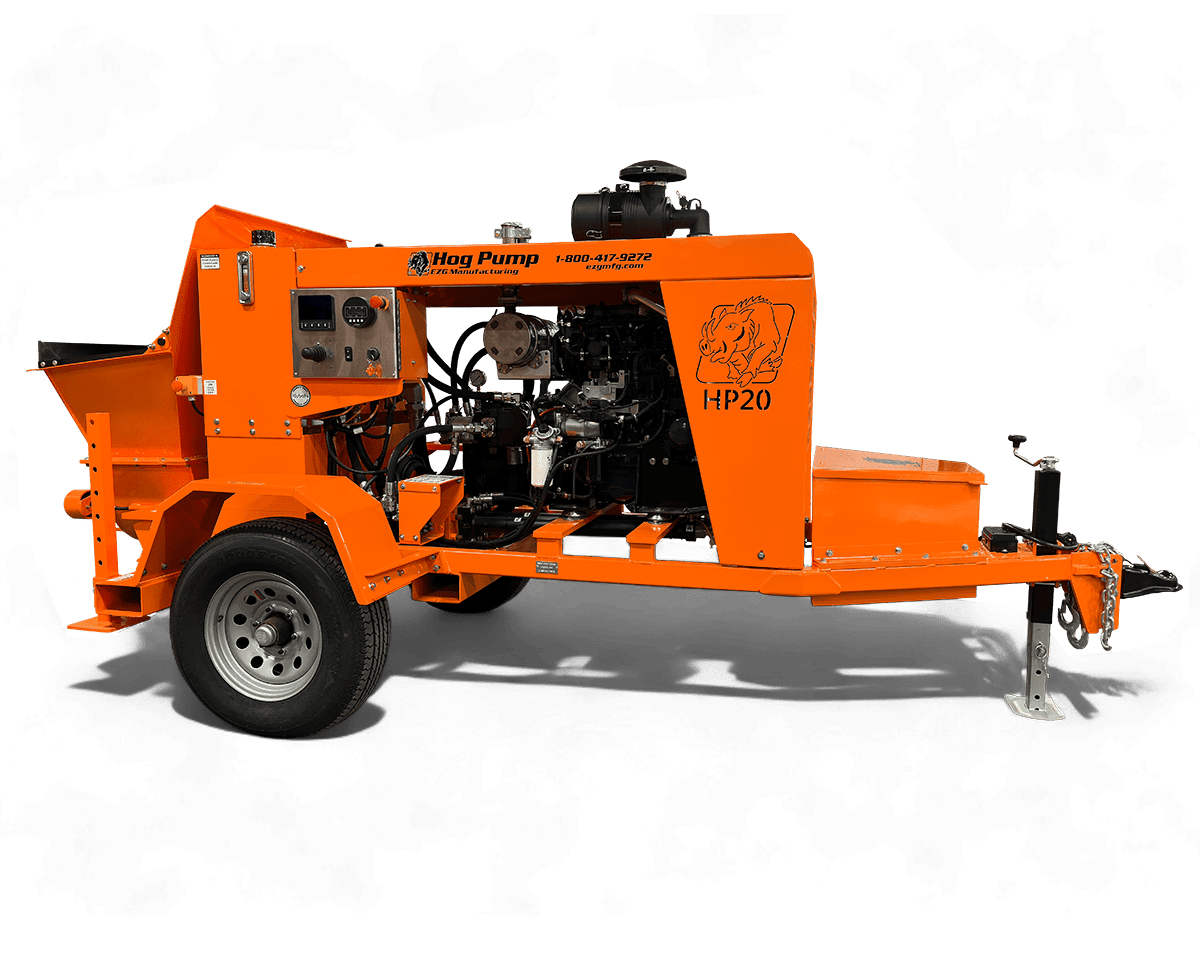

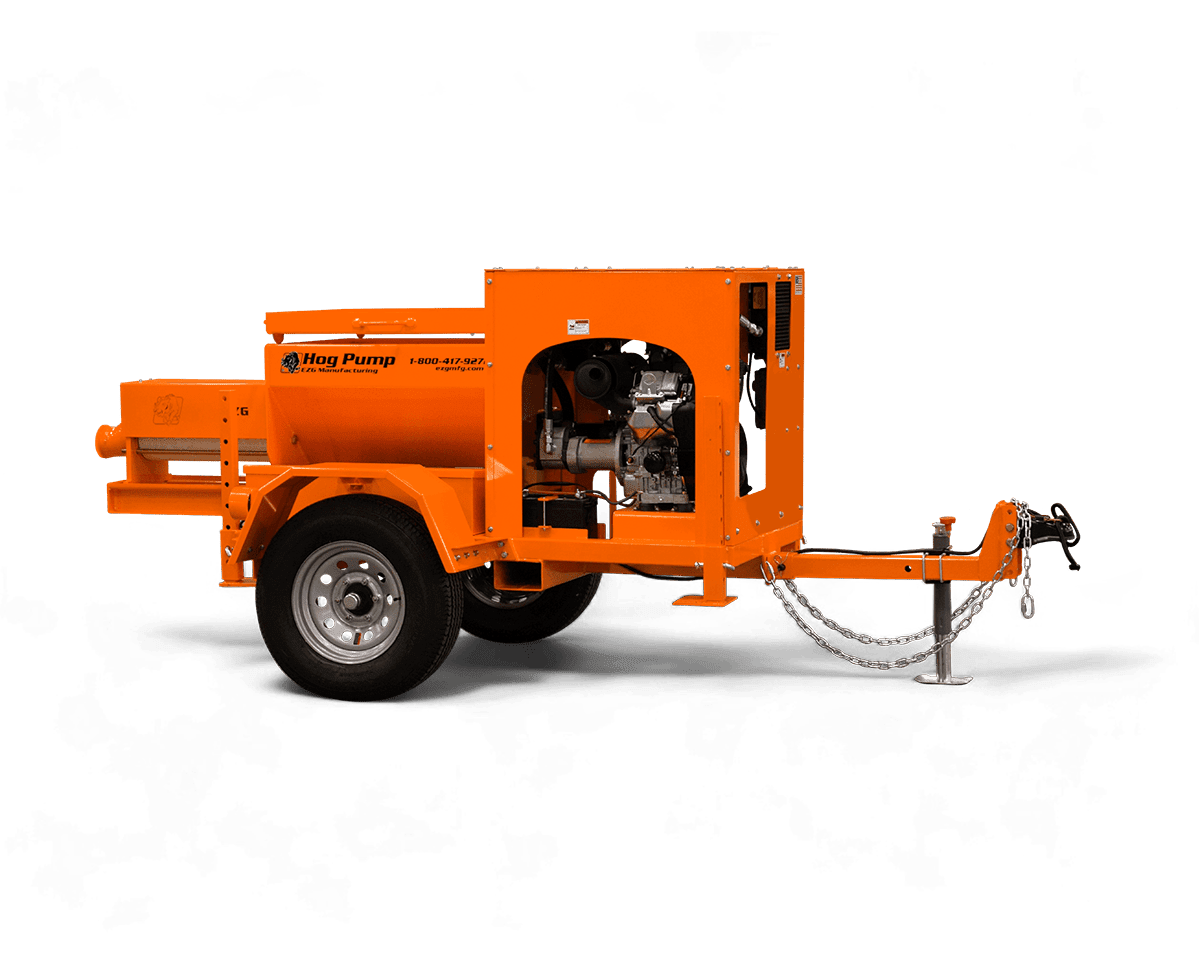

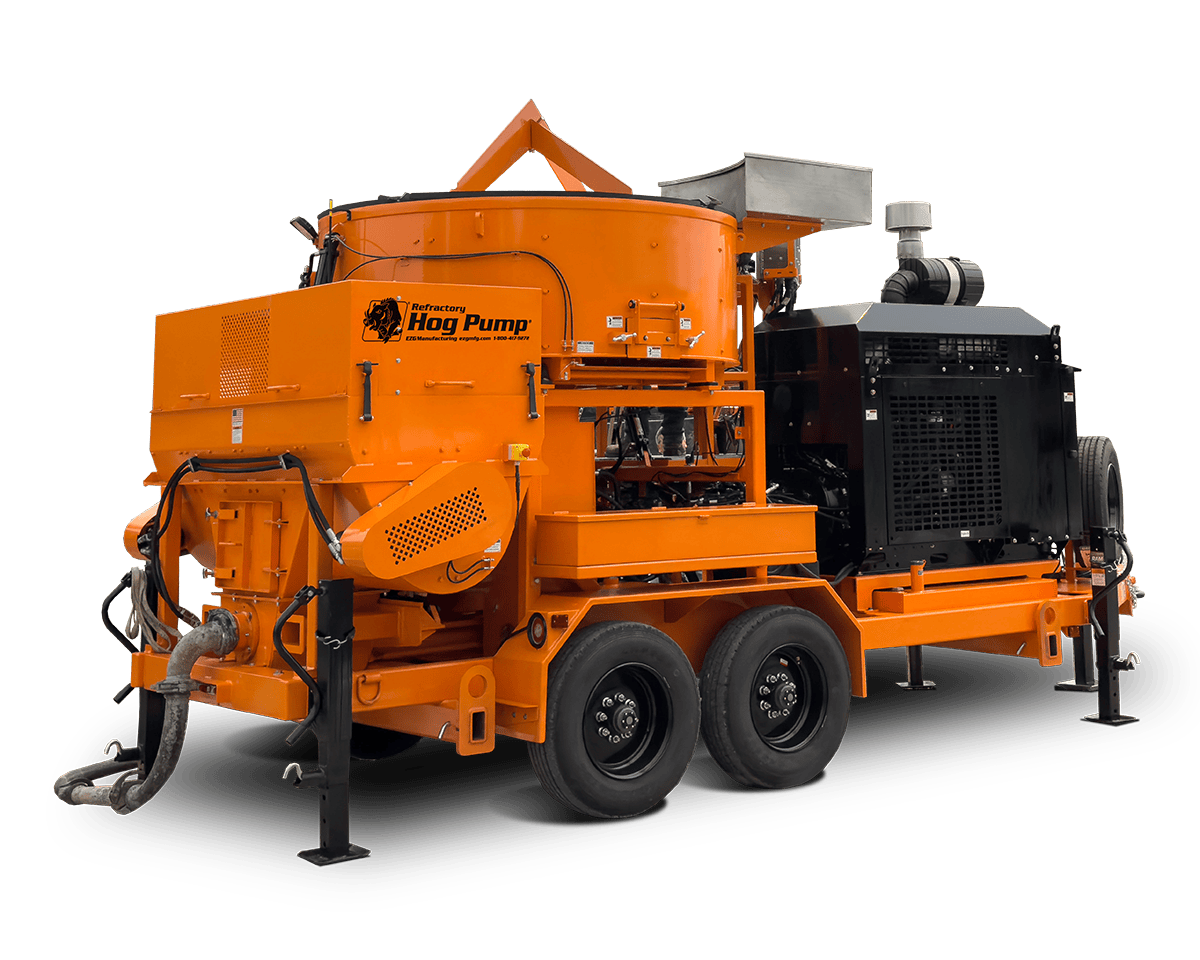

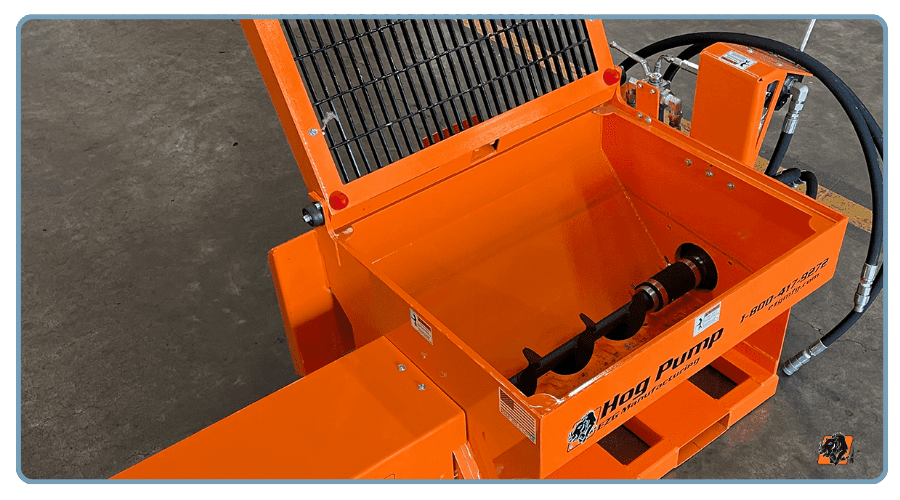

EZG Progressive Cavity Pumps — Controlled Concrete Flow for Tight or Long Runs

Crews dealing with 3/8″ ready mix, lightweight concrete, grout, shotcrete, or slurry know that moving material by hand slows the entire pour. These pumps use a progressive cavity system, which gives a smooth, controlled output instead of the uneven pulses you get from mechanical pumps.

The variable-speed hydraulics let you fine-tune the flow depending on the mix and application, and the reversible feature helps clear jams fast without breakdowns. Powered by a Kohler® ECH980 38 hp engine or by auxiliary hydraulics (38SS), the unit gives you the push needed for longer hose runs or tricky placements.

Contractor Benefits

- Clean, steady pumping for grout, lightweight concrete, or 3/8″ ready mix

- Adjustable speed for more precise placement in forms, voids, or footers

- Reversible flow to clear jams quickly

- Strong power output for long or elevated hose runs

If your crew hand-moves concrete into forms, this pump saves hours per job.

EZG Hog Slopper® — Faster Loading and Better Mixing Prep

The Hog Slopper® is designed to make batch prep faster and easier for crews who load mixers all day. It works as a materials scoop but is shaped and balanced to help crews load mixers quickly while keeping consistent proportions.

By reducing manual lifting and awkward angles, it cuts down on fatigue and makes mixing more uniform from batch to batch.

Contractor Benefits

- Faster loading for mixers and batch setups

- Helps achieve more consistent mix ratios

- Reduces strain and awkward lifting angles

- Speeds up the entire mixing process

For crews mixing dozens of batches per day, this simple attachment keeps production moving without taxing the team.

General Construction & Site Prep Attachments

These are the everyday essentials contractors rely on across all trades:

- Augers: Fast drilling for fence posts, piers, footings, and utility holes. Delivers uniform depth with far less manual digging, and handles tough soils better than handheld tools.

- Grapples: Strong grip for brush, scrap, debris, and demolition material. Speeds up cleanup and gives operators better control when moving awkward loads.

- Pallet Forks: Reliable lifting for block, lumber, stone, and banded supplies. Helps crews move material across uneven ground without strain or extra equipment.

- Hydraulic Breakers: Powerful impact for breaking concrete, asphalt, and rock. Useful for demo, utility cuts, and repair work where manual tools fall short.

- Soil Conditioners / Power Rakes: Smooths, levels, and preps ground for landscaping, hardscape, or new construction. Breaks up clumps, evens out surfaces, and leaves a clean base for the next stage of work.

Best Attachments by Trade

| Trade | Top Attachments | Why These Help |

|---|---|---|

| Masonry Contractors | Mobile Mud Hog®, Hog Slopper®, Hog Crusher®, Triple-Use Mixers, Progressive Cavity Pumps | Faster batching, less hauling, consistent mixes, on-site recycling, reduced fatigue, supports long wall runs |

| Fencing Contractors | Fence Hog®, Stretch-N-Go®, Barbwire Hog®, Fencer’s Cement Hog®, Augers | Controlled tension, safer wire handling, accurate concrete placement, faster post-hole drilling, smaller crews can do big runs |

| Concrete Contractors | Mobile Mud Hog®, Triple-Use Mixers, Progressive Cavity Pumps, Hog Slopper®, Grapples | Predictable batches, better placement, fewer wheelbarrow runs, cleaner pours, faster job turnover |

| General Contractors | Grapples, Pallet Forks, Augers, Breakers, Soil Conditioners, Hog Crusher® | Versatile day-to-day performance, faster material movement, demo capability, ground prep, cleanup |

| Hardscape Contractors | Hog Crusher®, Augers, Grapples, Soil Conditioners, Mobile Mud Hog® | Prepares base material, conditions soil, handles heavy block/paver pallets, crushes material for sub-base |

| Utility Contractors | Trench Mixer, Augers, Grapples, Progressive Cavity Pumps | Faster trench backfill, clean slurry placement, efficient pole hole drilling, debris clearing |

| Demolition Contractors | Grapples, Breakers, Hog Crusher®, Pallet Forks | Breaks concrete/asphalt, handles debris, crushes waste into reusable fill, moves heavy materials |

| Agricultural & Ranch Operations | Stretch-N-Go®, Barbwire Hog®, Fence Hog®, Augers, Cement Hog® | Easier wire handling, faster long pasture runs, post-hole drilling, accurate fence-line concrete placement |

Final Recommendations

Picking the right skid steer attachment comes down to one thing: what’s slowing your crew down the most?

- Mixing → Mobile Mud Hog®, Triple-Use Mixers, Hog Slopper®

- Waste management → Hog Crusher®

- Fence installation → Fence Hog®, Stretch-N-Go®, Barbwire Hog®, Cement Hog®

- Concrete flow → Progressive Cavity Pumps

- Daily jobsite tasks → Augers, grapples, breakers, forks

Skid steers become true production machines when you outfit them with tools that eliminate manual labor and keep the workflow moving.

EZG Manufacturing offers contractor-grade attachments built for real jobsite abuse. And our team can help match attachments to your hydraulic system, crew size, and trade.

If you need guidance choosing the right setup or specs, EZG’s experts can walk you through compatibility, jobsite scenarios, and real feedback from contractors doing the same work you do every day.