When you’re mixing concrete on the jobsite, the mixer you run has a direct impact on how fast the work moves, how hard your crew has to work to keep up, and how consistent the finished result turns out. It’s not just about having a mixer. It’s about choosing equipment that matches the way you actually build.

That’s why a lot of contractors end up weighing the same decision when it’s time to upgrade or add capacity: do you invest in a towable concrete mixer that can move from site to site, or a stationary concrete mixer that stays put?

What Does a Concrete Mixer Do in Daily Construction Work?

A concrete mixer combines cement, aggregate, water, and additives into a workable mix that can be placed before setting begins. Most mixers do this with a rotating or mixing drum that keeps the material rolling until it hits the right consistency, so you’re not fighting dry pockets or watery spots once you start placing.

People often call anything with a drum a “cement mixer,” but not every mixer is built for real concrete. Mortar mixers are made for masonry mixes and smaller aggregate, which is fine for block and brick work. A true concrete mixer is designed for heavier loads and larger aggregate.

While ready-mix concrete delivered by a cement truck works well for large pours, many construction projects rely on on-site mixing to manage timing, access, or batch size.

What Is a Stationary Concrete Mixer?

A stationary concrete mixer is fixed-position equipment designed to remain in one location during operation. These units are typically set up at a designated mixing area on a construction site or at a batch plant, where materials are brought to the mixer rather than the other way around.

Stationary mixers are available in various sizes and production capacities to match different project demands. You can find smaller units suited for job site use alongside large-scale industrial mixers capable of handling continuous concrete production.

How Stationary Mixers Work

The basic operation is straightforward: materials are loaded into the mixing drum, the drum rotates to blend the cement, aggregate, and water, and the finished concrete is discharged into wheelbarrows, buckets, or directly into forms. Power source options include electric mixer configurations for indoor or controlled environments, as well as gas or diesel engines for outdoor settings where electrical hookups are unavailable.

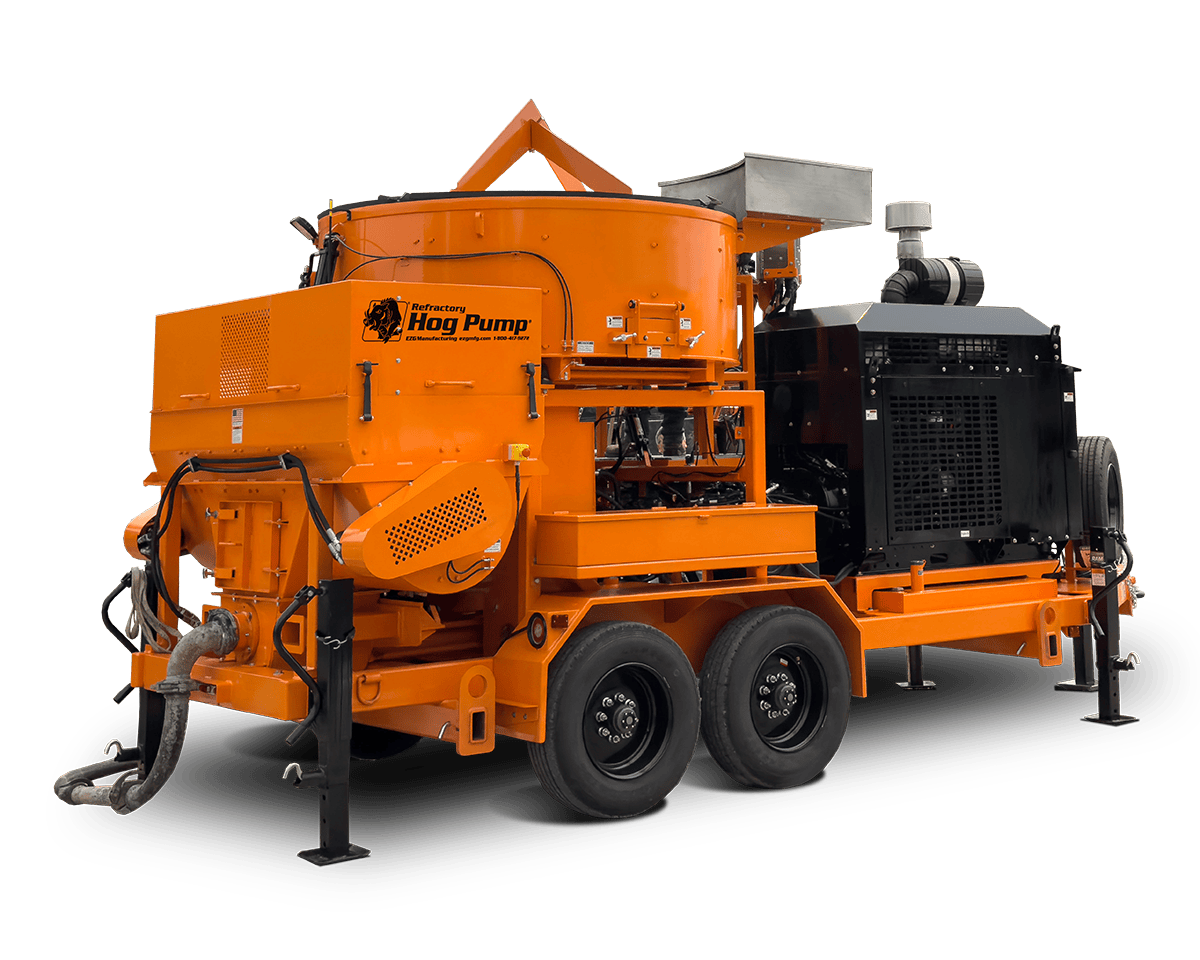

What Is a Towable Concrete Mixer?

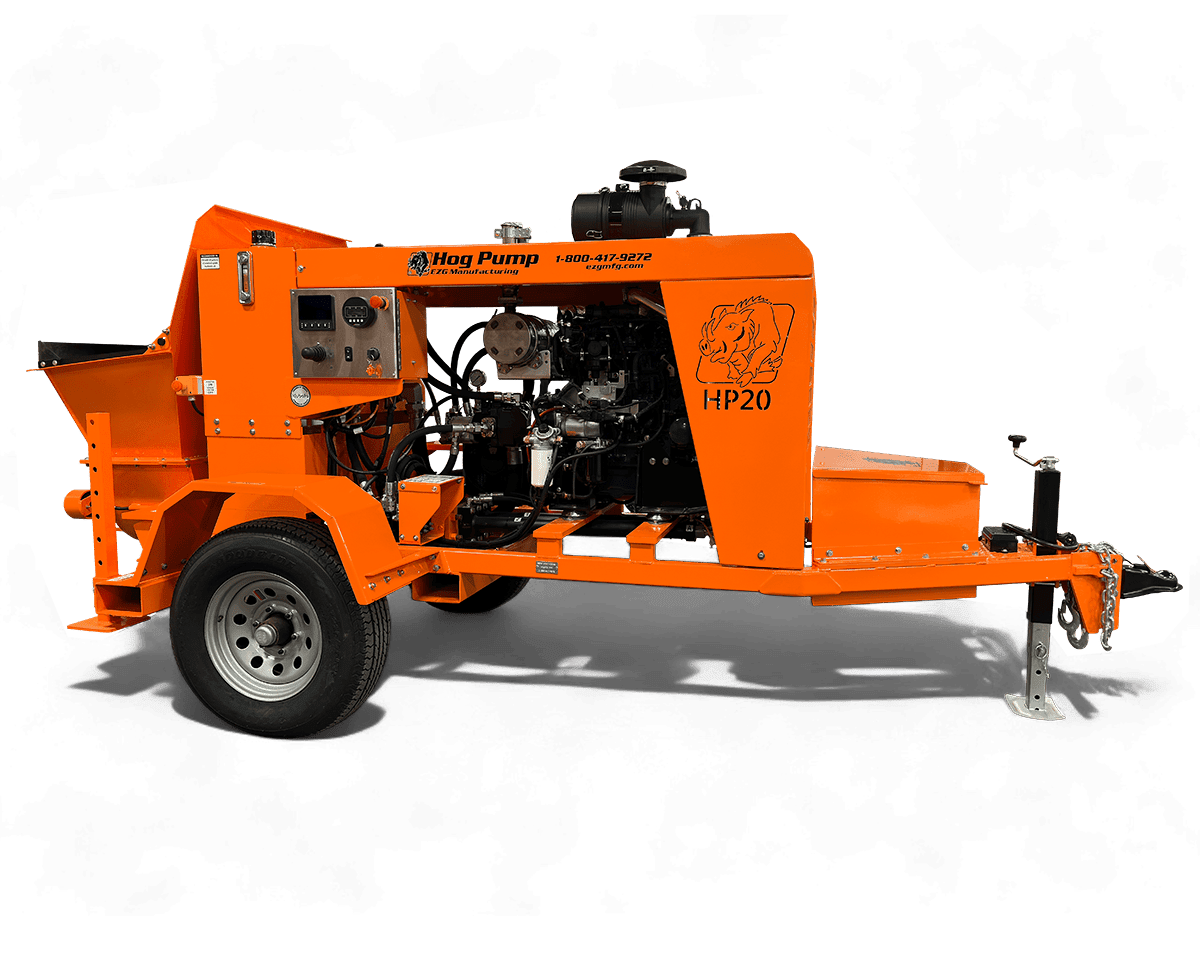

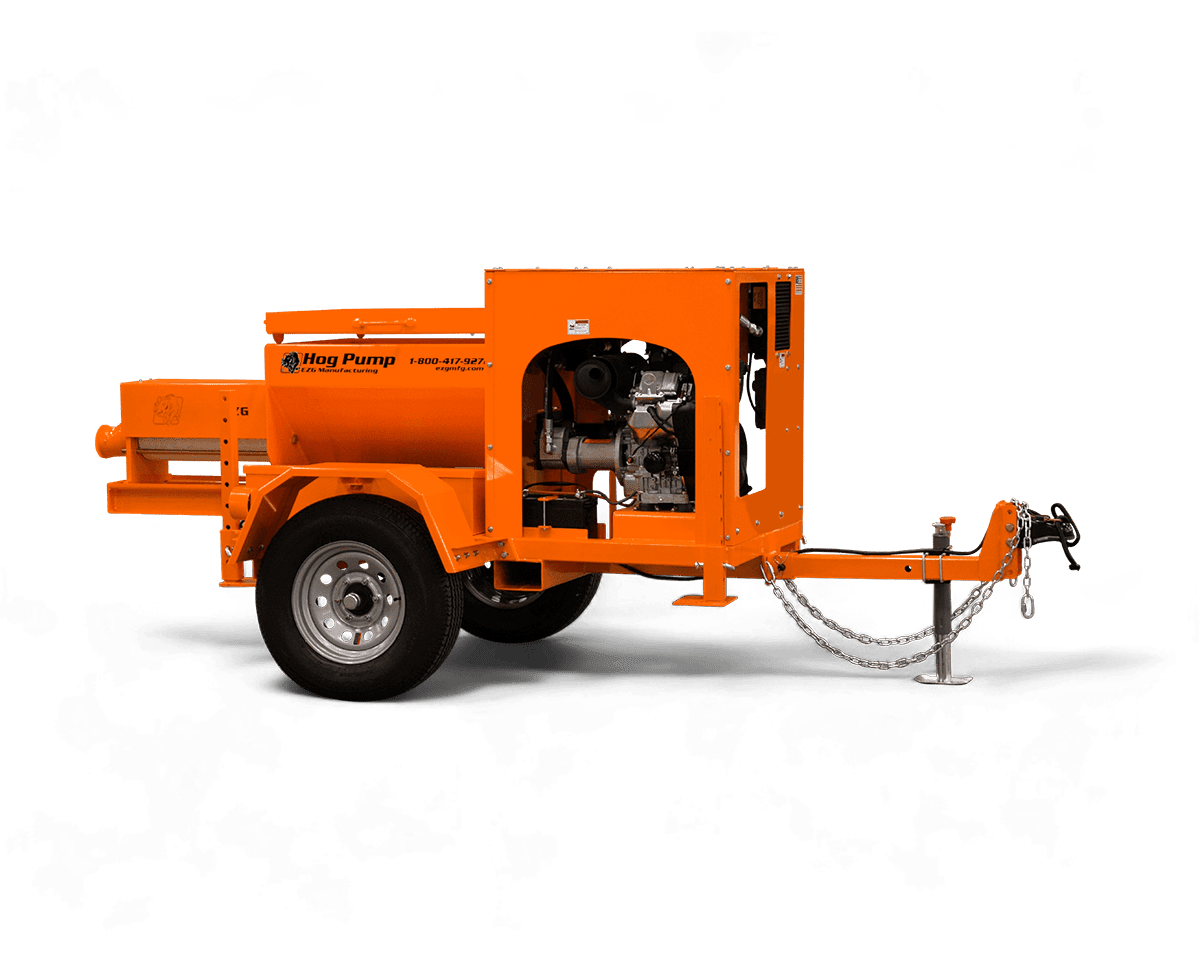

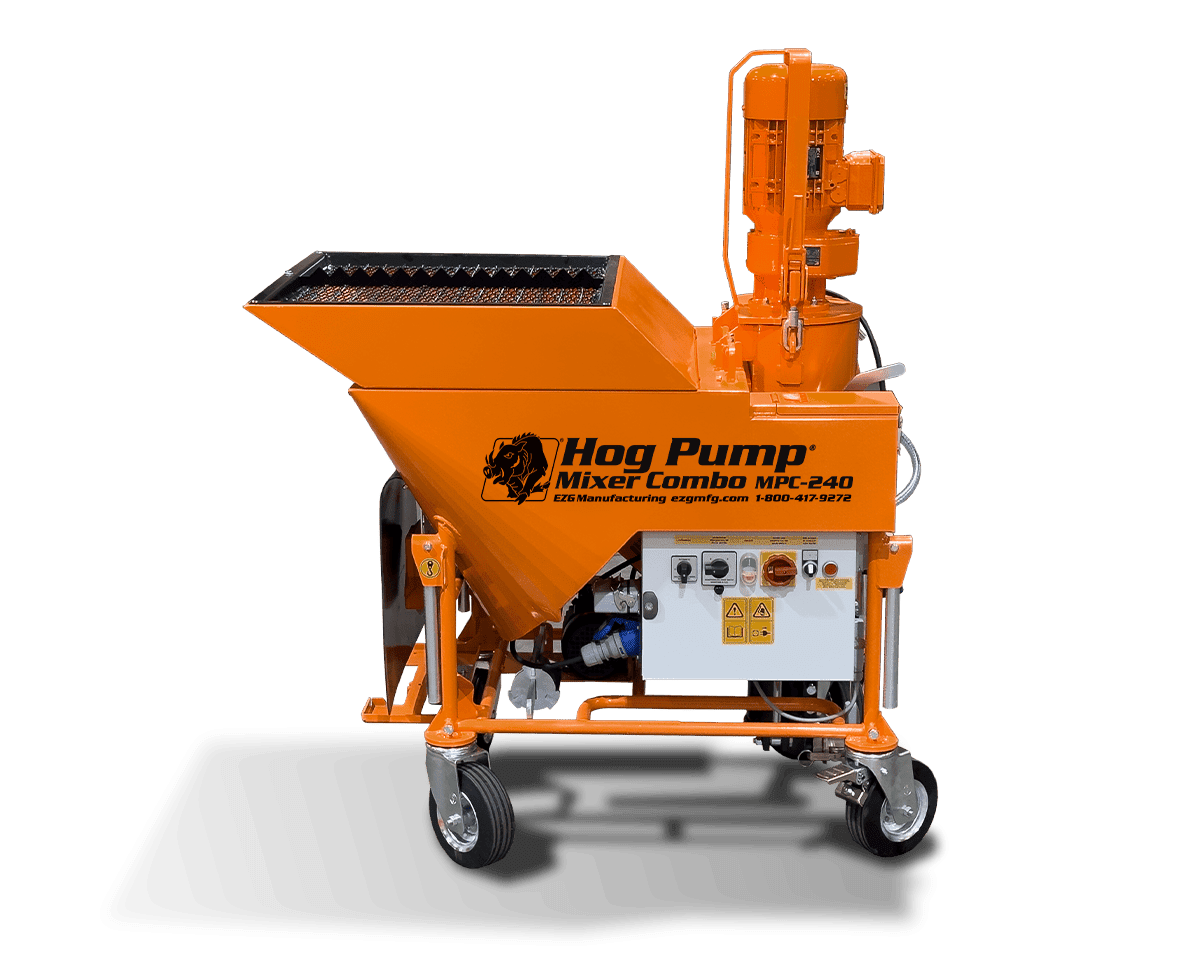

A towable concrete mixer is a portable unit mounted on a trailer frame with wheels, designed to be pulled by a truck or tractor. These mixers bring on-site mixing capabilities directly to where the concrete is needed, eliminating the back-and-forth that slows down traditional mixing setups.

Towable mixers are also referred to as portable concrete mixers or mobile concrete mixers. They range in capacity from smaller units handling a cubic yard or less to larger trailer-mounted models capable of mixing two to three cubic yards at a time.

How Towable Mixers Work

Materials are loaded into the rotating drum, which mixes the concrete during transport or at the pour location. Once the mix reaches the right consistency, the concrete is discharged directly where you need it. Many towable mixers feature rotating drum designs that keep the concrete workable during transit, reducing waste and improving efficiency.

The primary advantage is mixing fresh concrete right at the pour site. You are not waiting on cement truck deliveries or working around ready-mix concrete schedules. You decide when it gets mixed, where it gets mixed, and how fast you want to run the work.

Towable vs. Stationary Concrete Mixers

The right choice depends on where you work, how much concrete you need, and how often you move between job sites.

| Feature | Stationary Mixer | Towable Mixer |

|---|---|---|

| Mobility | Fixed location; requires forklift or crane to relocate | Towed behind a vehicle; moves easily between sites |

| Best For | High-volume projects, precast production, batch plants | Multi-site work, remote locations, smaller pours |

| Capacity Range | Often larger; 9–20+ cubic feet common | Varies; 1–3 cubic yards typical for trailer models |

| Setup Time | Longer initial setup; minimal repositioning | Quick setup; can be operational within minutes |

| Labor Requirements | May require dedicated mixing crew | Often a one-person operation |

| Power Source | Electric, gas, or diesel options | Typically gas or diesel; some electric options |

| Ideal Project Size | Large commercial and industrial projects | Small to medium residential and commercial projects |

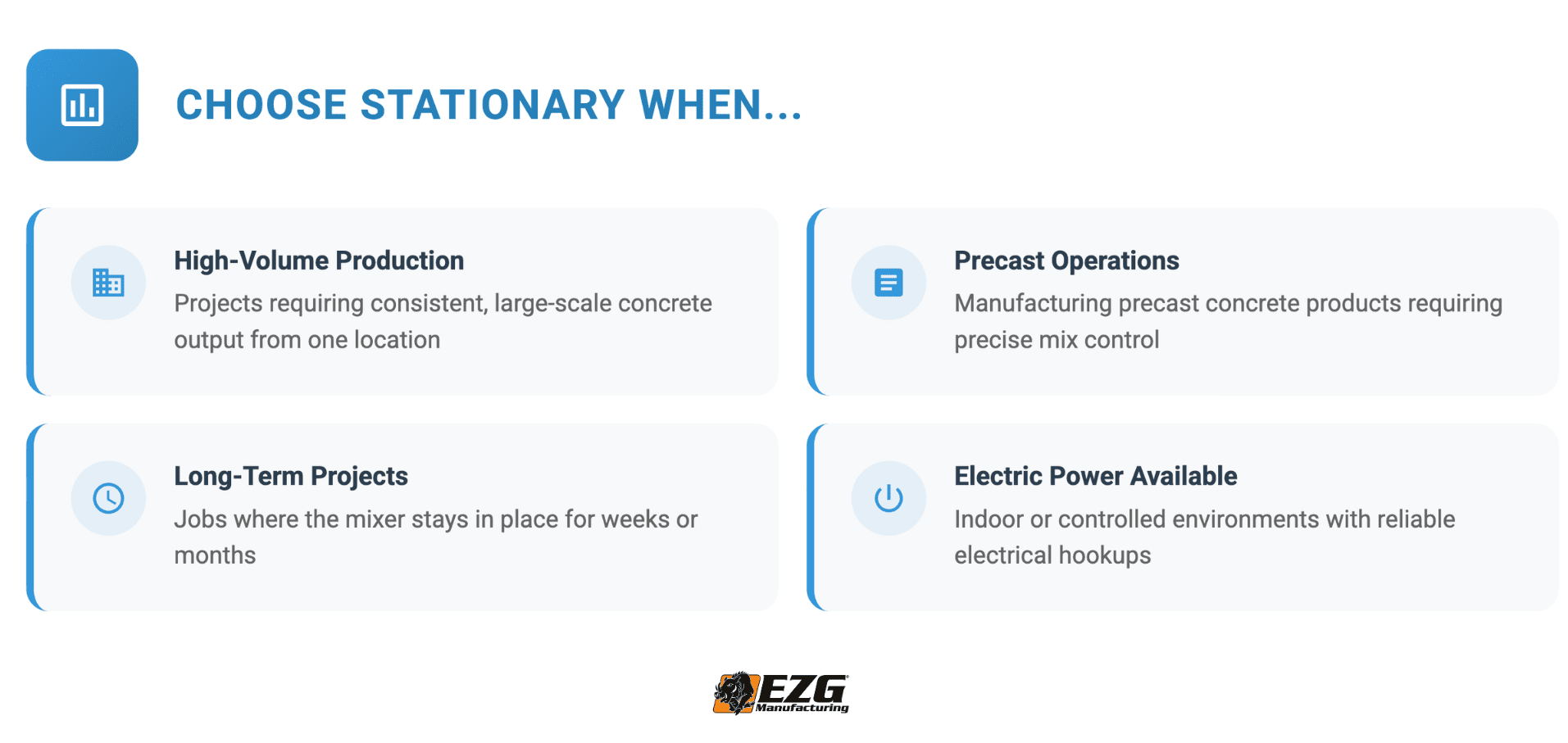

When to Choose a Stationary Concrete Mixer

Stationary mixers is the right call when you need consistent, high-volume concrete production from a single location. If you have the space for a permanent or semi-permanent mixing setup and your work keeps you in one place for extended periods, a stationary unit delivers the production capacity you need.

Consider a stationary concrete mixer when you are running precast operations that require high-quality concrete with precise mix control, working on long-term projects where the mixer will remain in place for weeks or months, operating in a facility with reliable electric power for cleaner operation, or producing large volumes of concrete that would overwhelm smaller portable units.

Advantages of Stationary Mixers

Stationary mixers are built for higher output and repeatable results. Because the mixer stays planted, you get a stable setup that supports consistent mixing and a more predictable workflow. Many models also offer more advanced features for automated mixing and discharge, which can tighten up your process and reduce the amount of hands-on labor required per batch. Since the unit isn’t being towed or bounced between jobs, you also avoid a lot of the wear and tear that comes with transport, which can help with longevity over time.

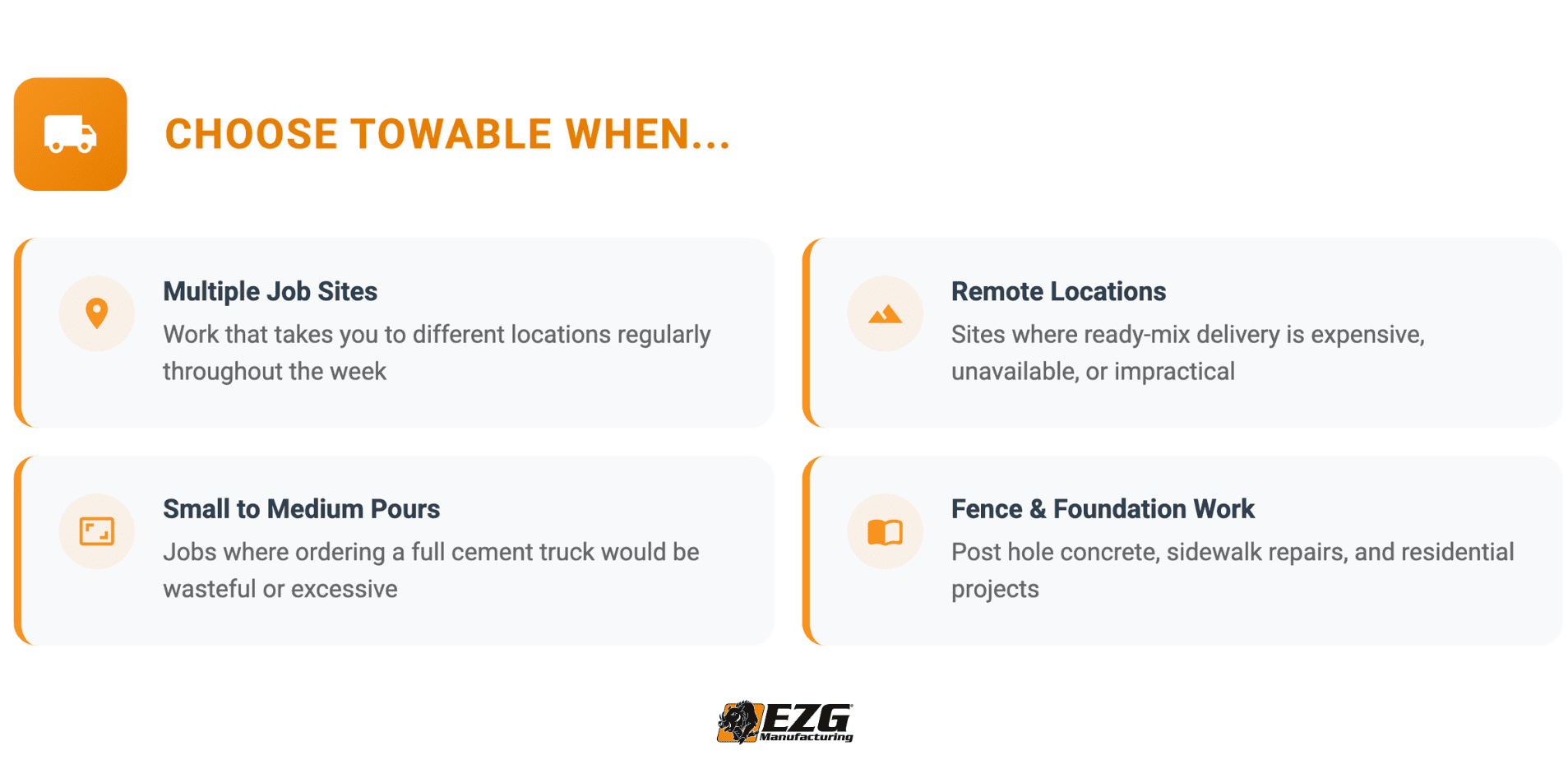

When to Choose a Towable Concrete Mixer

Towable mixers are ideal when mobility and flexibility are top priorities. If your work takes you across multiple job sites, a portable concrete mixer travels with you and eliminates dependence on delivery schedules.

Towable mixers make the most sense when you’re working in remote areas where ready-mix delivery is expensive, delayed, or not available at all, handling small to medium pours where ordering a full truck would be overkill, and doing work that is broken up into repeat jobs like fence and post holes, sidewalk and curb repairs, or residential flatwork.

Advantages of Towable Mixers

The biggest advantage is that the mixer goes wherever your truck can go, which gives you the freedom to work across multiple sites without changing your setup. That mobility can also reduce labor because you can mix closer to the pour, cut down on hauling, and keep the workflow tight, which is especially valuable on smaller jobs where every extra step eats into profit. A towable mixer also takes delivery schedules out of the equation, so you can start when you’re ready, pause when you need to, and finish without worrying about a truck showing up early or late.

For contractors who value control over their schedule and need to stay productive across multiple sites, a portable cement mixer pays for itself quickly.

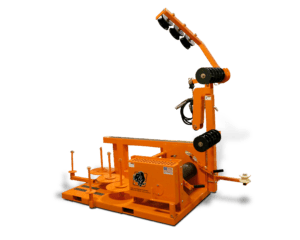

A Third Option: Mobile Skid Steer Mixers

For contractors who need something between a stationary setup and a trailer-mounted unit, mobile skid steer mixers offer a hybrid solution. These attachments turn your skid steer into a mobile concrete mixer, allowing you to load, mix, transport, and pour without leaving the seat.

Skid steer-mounted mixers are particularly effective for fence post concrete, hardscape work, and rough terrain sites where trailer-mounted units struggle to maneuver. You move the mixer to the materials, load up, and drive directly to the pour site. One operator handles what used to require a full crew.

EZG’s Mobile Mud Hog is designed for exactly this kind of work. With capacities ranging from 4 to 20 cubic feet and drum thickness up to 3/8-inch steel, these mixers handle concrete, grout, and mortar across the toughest terrain. Contractors have reported filling 80 post holes in 30 minutes with the Mobile Mud Hog, dramatically cutting labor time on fence and foundation projects.

EZG Manufacturing Concrete Mixing Solutions

EZG Manufacturing builds concrete equipment based on real-world contractor experience. Cheap mixers that clogged, broke down, and cost more in repairs and downtime than they were worth. EZG was built to solve that problem.

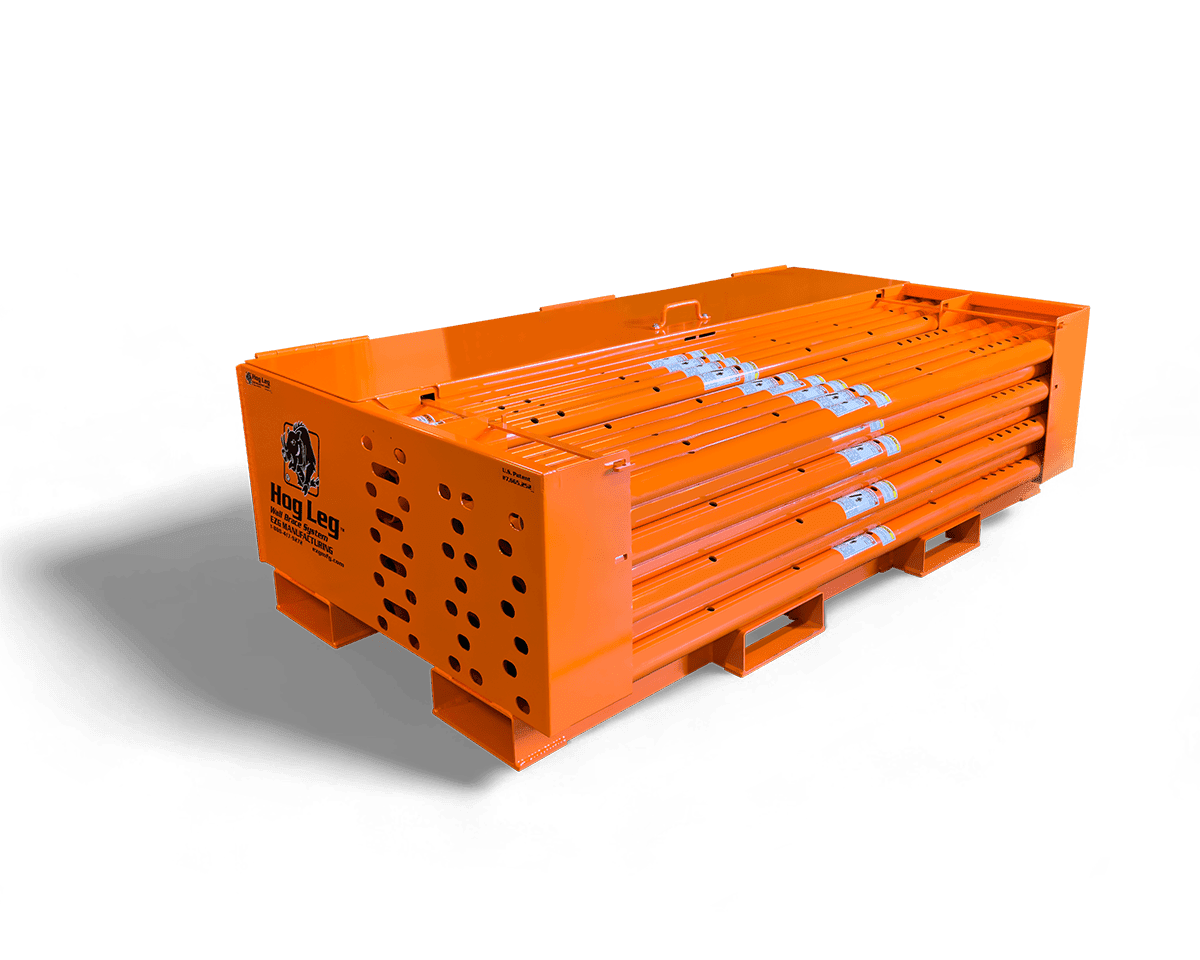

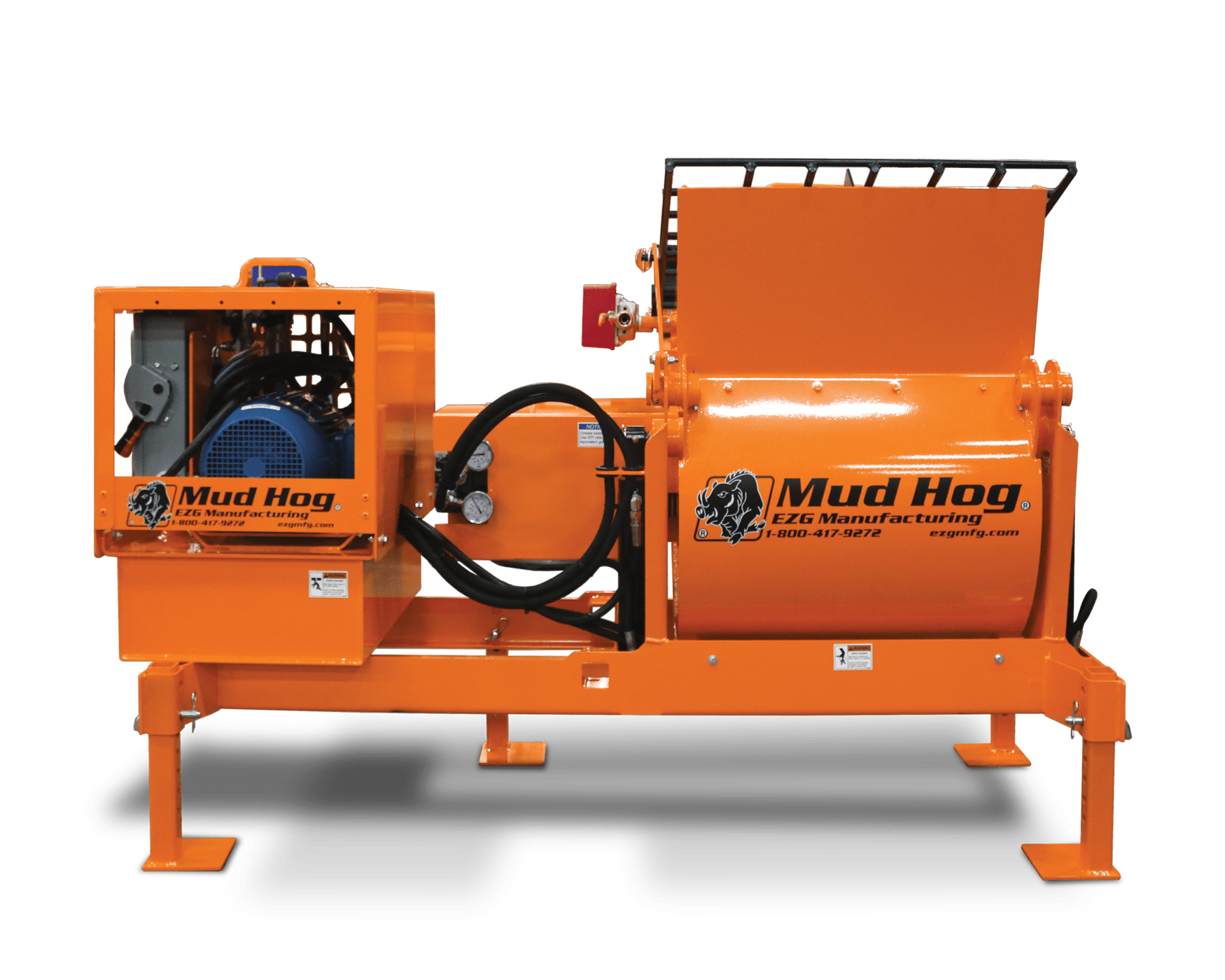

Mud Hog Hydraulic Mixers

The Mud Hog line is a triple-use mixer for mortar, grout, and concrete. These hydraulic mixers feature low loading height and high dump capability to reduce labor fatigue, a patented rubber blade design that prevents clogging, available capacities of 9, 12, and 20 cubic feet, and electric, gas, or diesel power options.

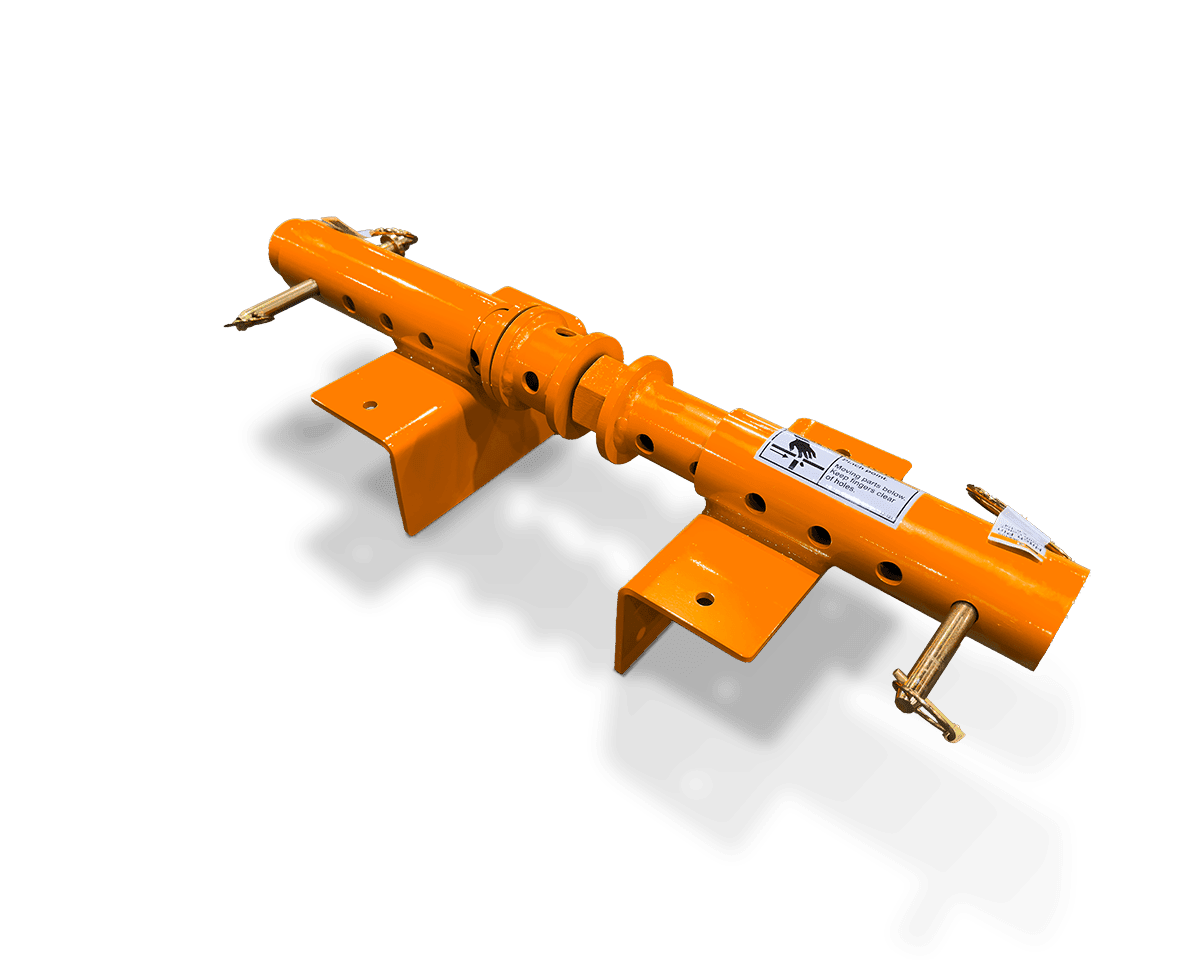

Manual Dump Mixers

For contractors looking for a budget-friendly option, EZG Manual Dump Mixers handle heavy aggregates right on the job site. Multiple capacity options make it easy to match the mixer to your typical project size.

How to Choose the Right Concrete Mixer for Your Operation

Selecting the right mixer comes down to answering a few key questions about your work:

What is the typical size of your concrete pours? Larger pours may benefit from stationary mixers with higher production capacity. Smaller, varied pours suit towable or mobile options that give you flexibility.

How many job sites do you work on? If you move between multiple locations regularly, portable or towable concrete mixers keep you productive without waiting on deliveries.

What is your access situation? Remote sites or tight-access areas benefit from mobile skid steer mixers that go where trailers cannot.

What is your budget for equipment and ongoing maintenance? Consider the total cost of ownership, not just the purchase price. A cheaper mixer that breaks down constantly costs more in the long run than quality equipment built to last.

How important is equipment reliability to your operation? Downtime costs money. Investing in mixers built for high reliability keeps your crews working instead of waiting on repairs.

Get the Job Done with the Right Mixer

Both towable and stationary concrete mixers have their place in the construction industry. The right choice depends on your project requirements, how you operate, and what kind of equipment fits your workflow.

What matters most is investing in concrete equipment that performs when you need it.

EZG Manufacturing builds mixers for contractors who cannot afford to have equipment fail on the job site. Every product is designed based on field experience, built with heavy-duty materials, and backed by a team that understands what it takes to get the job done.

Browse EZG’s full lineup of mixers or call our team to find the right solution for your job site.