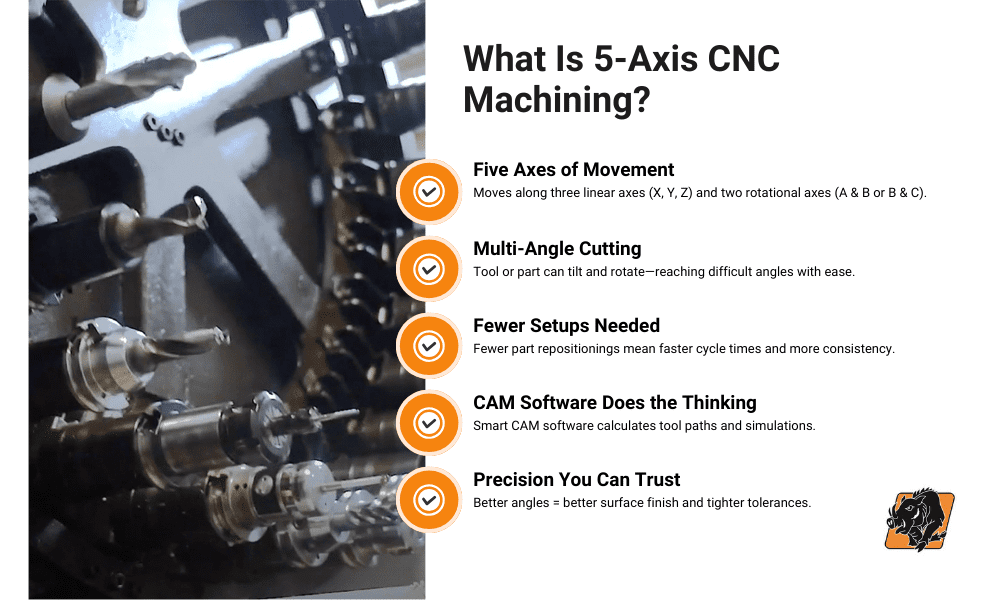

Quick Answer: A 5-axis CNC machine is a computer-controlled system that moves a cutting tool or part along five different axes, three linear (X, Y, Z) and two rotational (A and B or B and C). This added motion allows manufacturers to machine complex parts in a single setup, reducing time and improving precision.

CNC machines have changed how the world builds. Adding more axes to the process simply means more freedom to shape, cut, and contour a part from multiple angles. In this guide, we’ll break down what 5-axis CNC machining means, how it works in the manufacturing process, and how it compares to more traditional systems like 3-axis machines.

What Is CNC Machining?

CNC stands for Computer Numerical Control. These machines follow programmed instructions (known as G-code) to move tools with high accuracy and repeatability. The cutting tool or the workpiece moves along defined axes to shape the material according to the programmed design.

The Role of Axes in Machining

In a standard CNC setup, machines operate along three primary linear axes:

- X-axis: left to right

- Y-axis: front to back

- Z-axis: up and down

What About Rotational Axes?

5-axis CNC machines introduce two additional rotational axes, often labeled as:

- A-axis: rotation around the X-axis (tilts the part forward/backward)

- B-axis: rotation around the Y-axis (tilts side to side)

- C-axis: rotation around the Z-axis (spins the part)

Typically, a 5-axis machine will use A and B or B and C. This extra range of motion allows parts to be machined from virtually any angle without needing to reposition them manually.

How 5-Axis CNC Machining Works

5-axis CNC machining refers to a machining process where the cutting tool or part moves along five different axes at once, three linear (X, Y, Z) and two rotational (typically A and B or B and C). This added flexibility allows manufacturers to cut complex shapes and surfaces in a single setup. By continuously adjusting the tool’s orientation, 5-axis machines can reach difficult angles, reduce repositioning, and improve overall machining efficiency for intricate designs.

The Two Extra Axes

A 5-axis machine adds rotation to the motion. This happens in one of two common ways:

- Swivel head (B-axis): The cutting tool tilts

- Rotary table (C-axis): The workpiece rotates

Simultaneous vs. 3+2 Axis Machining

There are two common variations of 5-axis machining:

- Simultaneous 5-axis machining: All five axes move at once. This is useful for intricate contours or organic surfaces.

- 3+2 machining: Two axes are used to orient the part, and the remaining three handle the cutting. This is often more affordable and still effective for many parts.

Benefits of 5-Axis CNC Machines

- Machine complex shapes in one setup

- Shorter cycle time due to fewer part repositionings

- Better surface finish with optimal tool angles

- Reduced need for fixtures or jigs

- Improved tool life and cutting performance

5-Axis vs. 3-Axis CNC Machining

A 3-axis CNC system controls movement along X, Y, and Z axes. It’s well-suited for cutting flat parts, drilling holes, and machining features on a single plane.

These machines are effective for simpler components but require repositioning to reach other sides or angles.

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Motion Axes | X, Y, Z | X, Y, Z + A/B or B/C |

| Complexity | Basic flat parts, holes | Complex curves, multi-angle cuts |

| Repositioning | Often required | Rarely needed |

| Setup Time | Higher | Lower |

| Surface Finish | Moderate | High precision |

When to Use Each

- 3-axis milling machines are ideal for flat parts, basic cuts, and short runs

- 5-axis CNC machines work when a part has deep pockets, multiple angles, or needs to be machined in one setup

Industries That Use 5-Axis CNC Machining

Aerospace and Defense

Aircraft components often require tight tolerances and aerodynamic surfaces. 5-axis machines are used to create engine parts, housings, and wing sections without compromise.

Medical and Dental

From surgical tools to custom implants, the medical industry requires complex shapes in stainless steel, titanium, or polymers. The ability to machine intricate designs in one pass is a major advantage.

Automotive and Motorsports

Parts like brackets, pistons, intake manifolds, and suspension components benefit from the high accuracy and multi-angle approach of 5-axis milling.

Mold Making and Tooling

Molds for plastic injection or die-casting require complex cavities and smooth surfaces, both of which are handled efficiently with simultaneous 5-axis capabilities.

Main Parts of a 5-Axis Machine

Powerful Spindle

The spindle spins the cutting tool at high speeds and determines the material removal rate. Higher torque and speed help cut harder metals efficiently.

Rotary Table or Swivel Head

These allow for the rotation of the part or tool. Some machines rotate the table; others rotate the spindle head. This provides flexibility in setup and design.

CAM Software and Tool Paths

Without smart programming, the motion of five axes is hard to control. Modern CAM software calculates tool paths automatically and supports simulation before cutting begins.

Stepper Motors and Accuracy

Stepper or servo motors drive each axis. Their responsiveness contributes to high positional accuracy, especially during tight maneuvers.

Common Myths About 5-Sided Machining

- “Only for big manufacturers”: Many small to mid-size shops now use 5-axis systems thanks to affordable models and better software.

- “Difficult to program”: CAM platforms are now user-friendly and can automatically generate code for 5-axis work.

- “Too expensive”: The upfront cost is higher, but savings come from fewer setups, less manual intervention, and faster production.

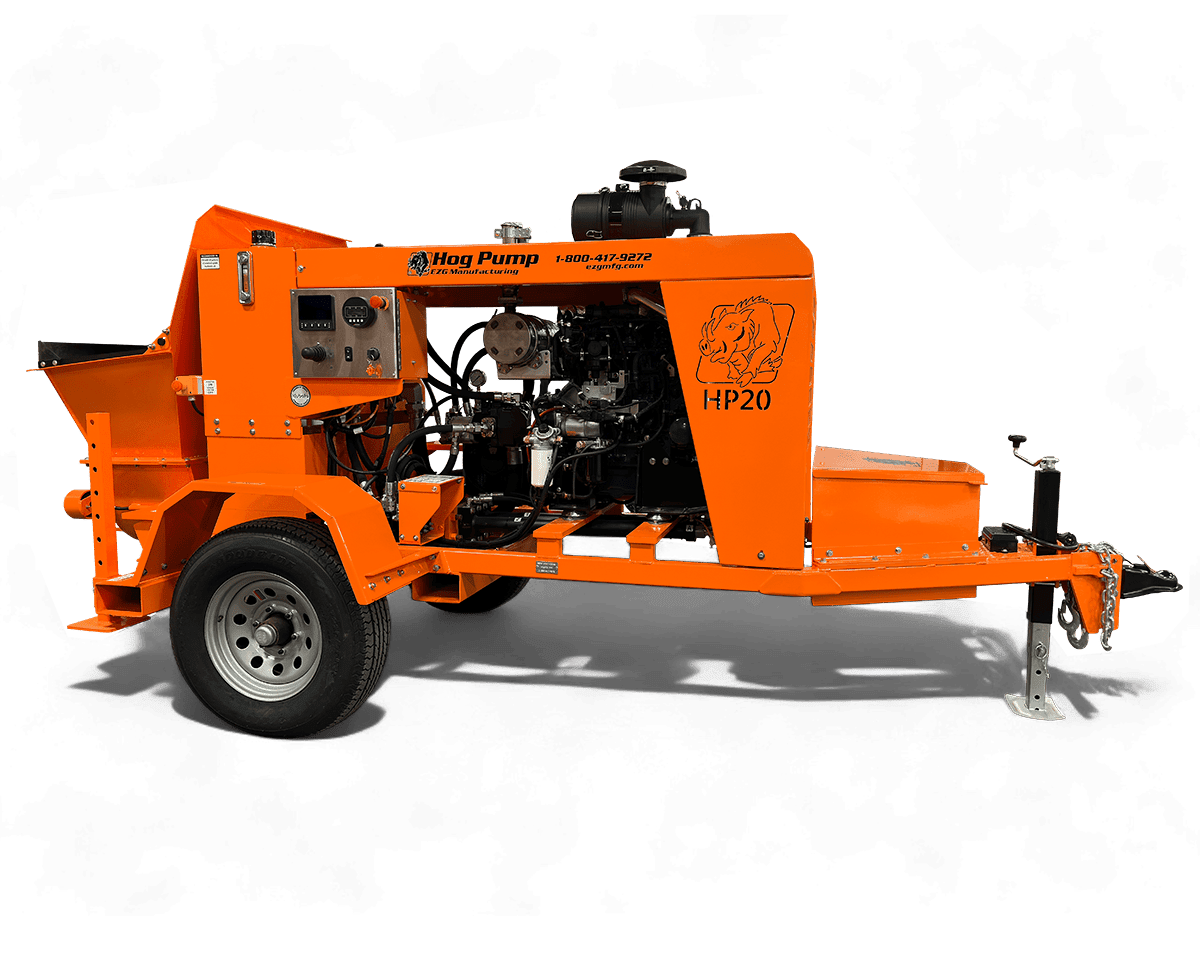

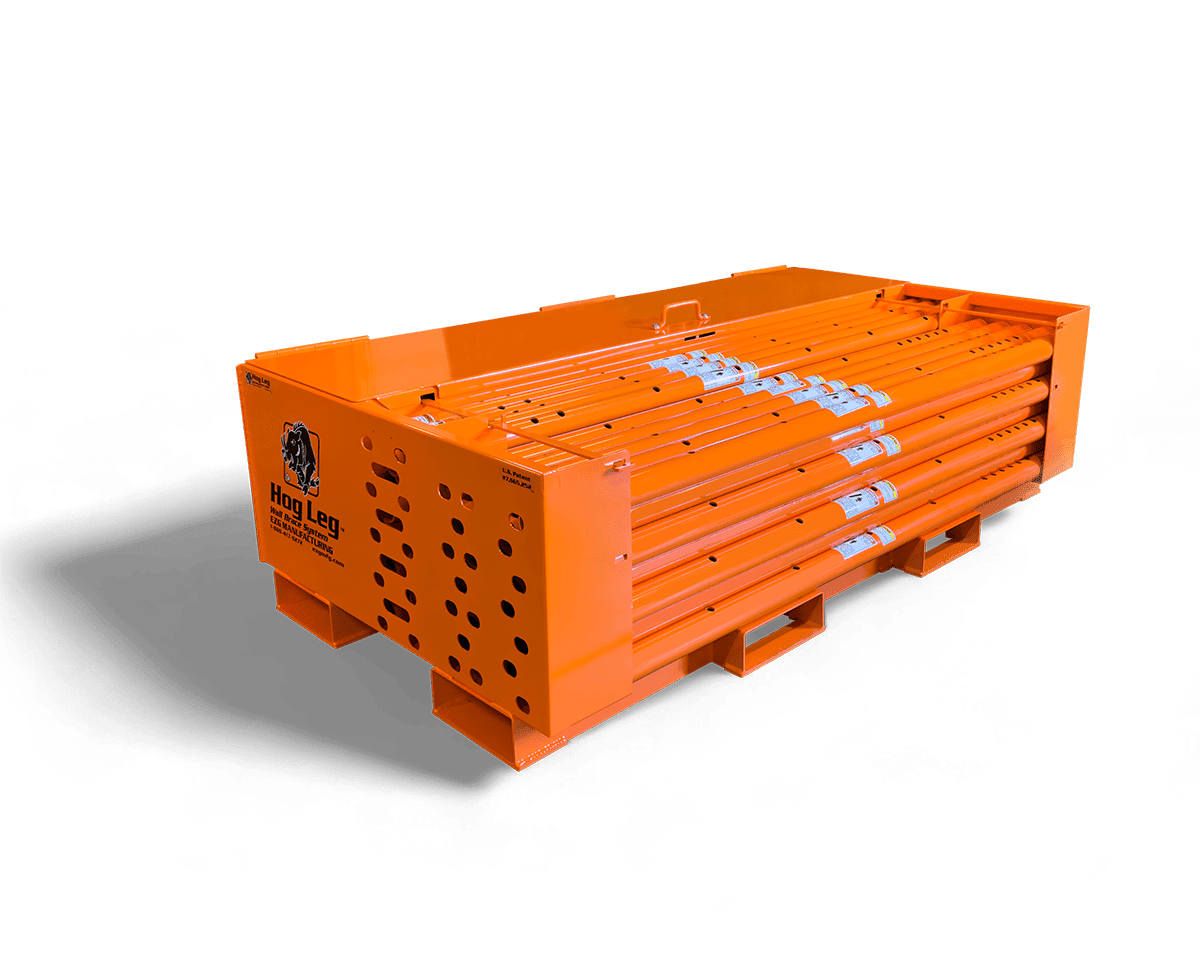

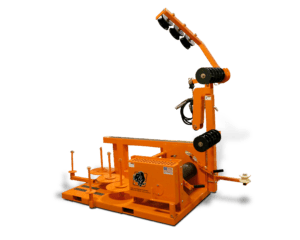

EZG Manufacturing’s CNC Capabilities

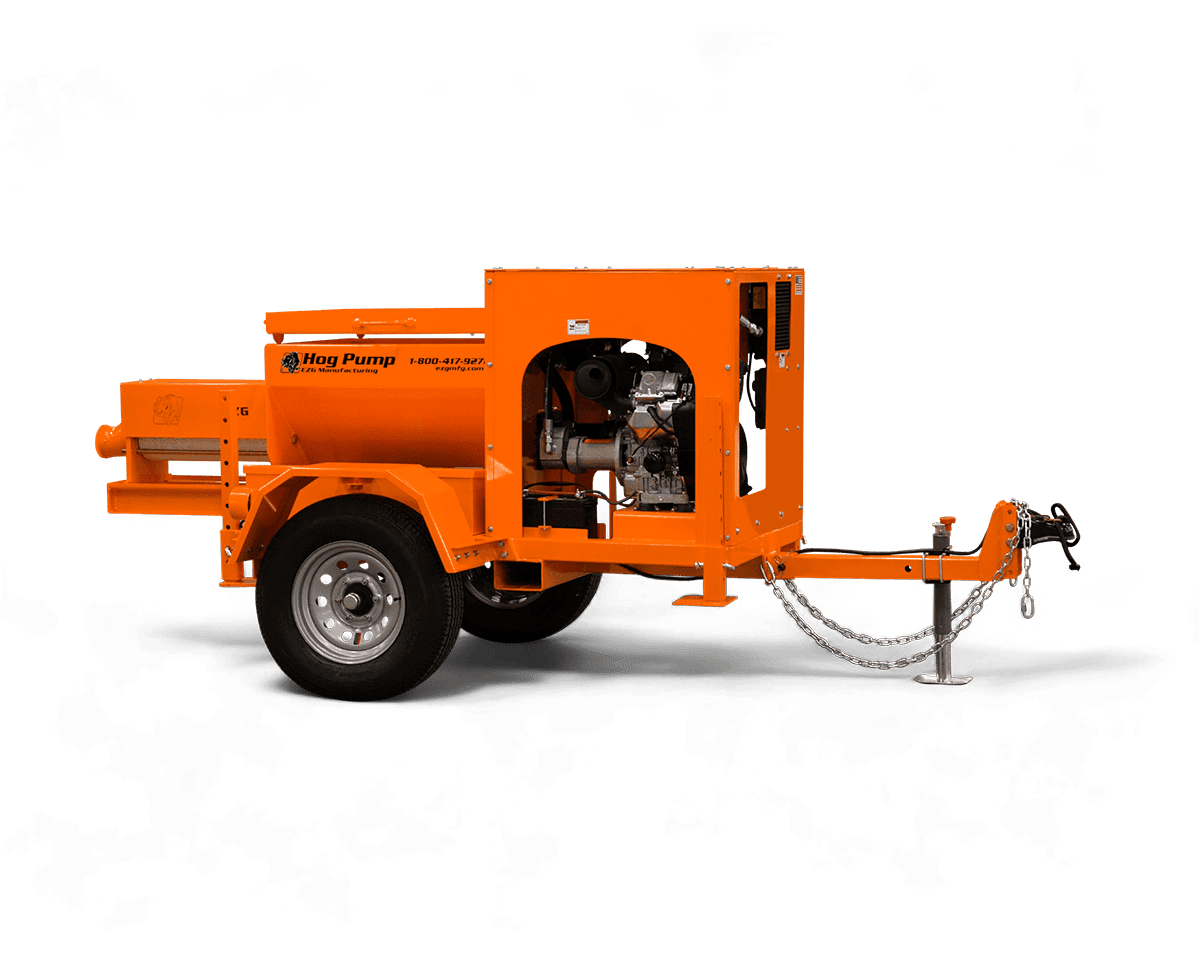

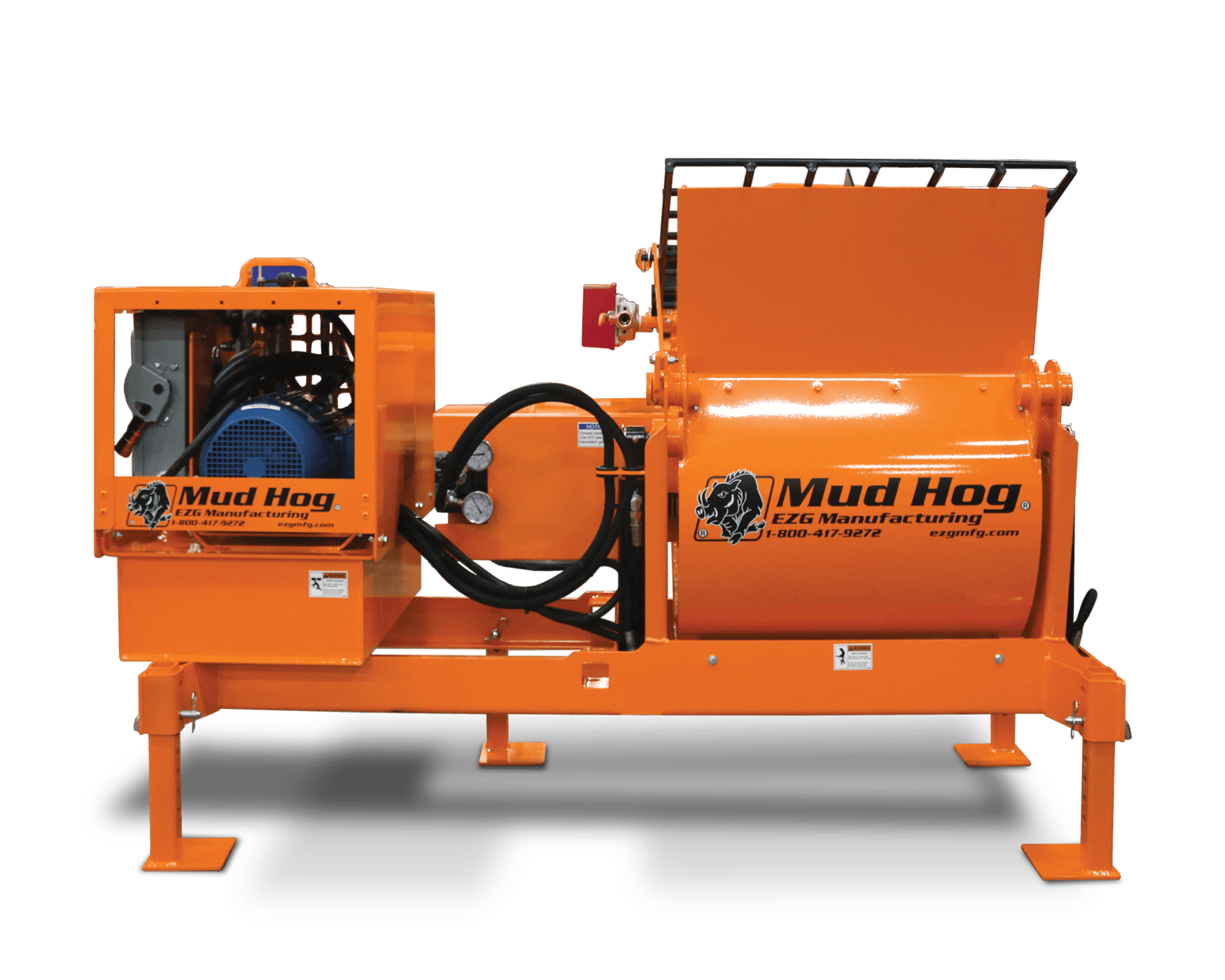

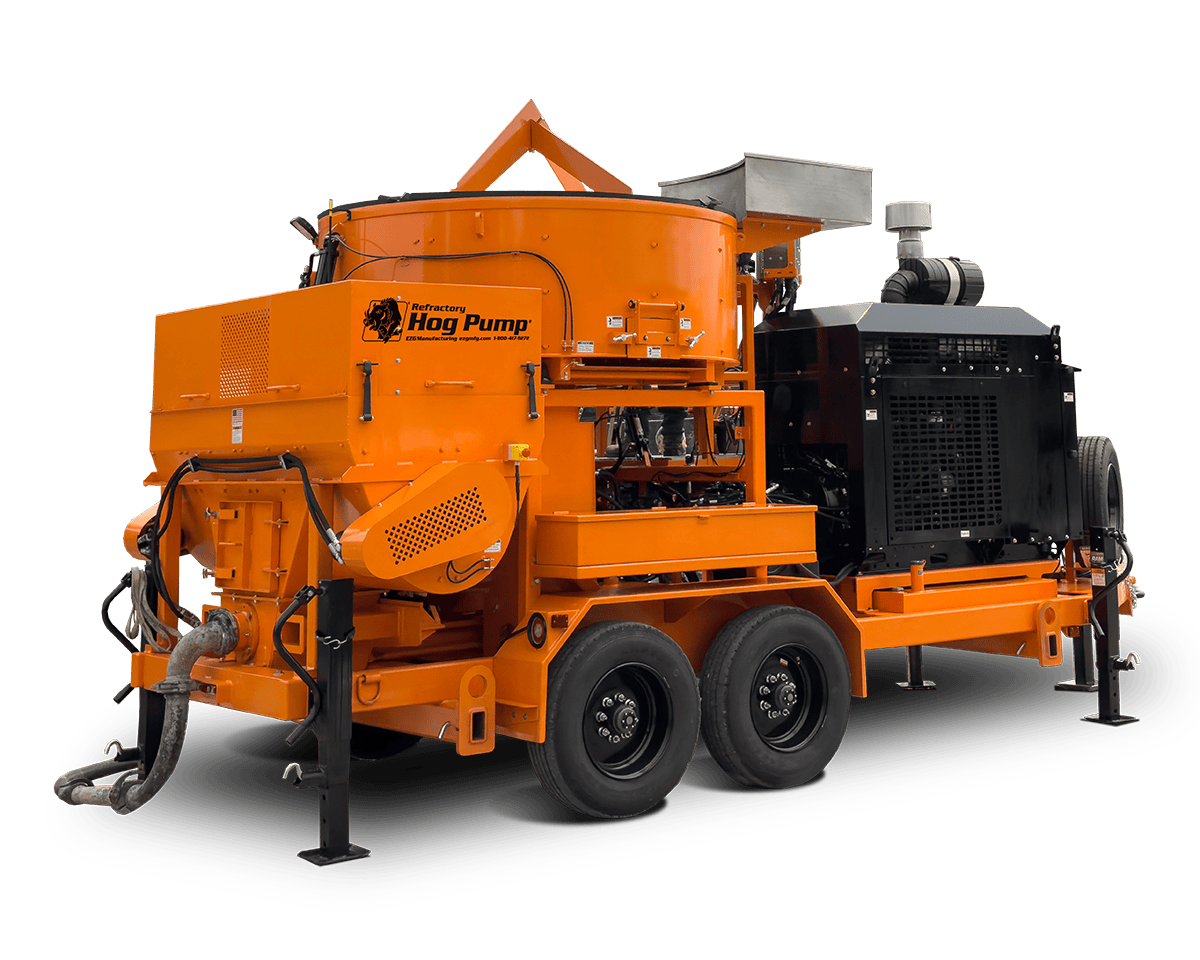

EZG Manufacturing operates as a built-to-print contract manufacturing partner with a focus on getting it right the first time.

We work with multiple CNC milling and turning centers, including large-format systems capable of handling structural steel up to 40 feet long. Our in-house team can machine everything from small, intricate components to oversized fabrications, eliminating the need to send parts off to third parties.

Whether you need 5-axis machining, robotic welding, powder coating, or laser cutting, we handle 90%+ of the process in-house. That means faster turnaround, better quality control, and consistent communication.

Talk to Our Team About Your Project Now

Looking for a team that can handle complex geometries, tight tolerances, and multi-process builds? EZG Manufacturing is ready to help.

Contact us to learn more about how we can support your next CNC machining project.