The oil and gas industry depends on equipment that can run for years under pressure, high heat, and tough conditions. From storage tanks and production units to control equipment and pumps, each part of the operation represents a major investment. Extending the life of this equipment reduces downtime, lowers repair costs, and keeps operations moving efficiently.

Companies in the gas sector are always asking: How do we make our equipment last longer? The answer lies in good maintenance, predictive monitoring, and choosing equipment designed for durability.

At EZG Manufacturing, we build custom oil and gas processing equipment with these challenges in mind. By focusing on quality fabrication, advanced features, and long-term performance, our equipment helps operators in gas fields and facilities get more years out of every unit.

Understanding the Role of Equipment in the Gas Industry

Oil and gas production relies on a variety of machines and systems, each serving a purpose in extracting, processing, and delivering natural gas and crude oil safely. Equipment is important at every stage in the operation. Everything from gas drilling rigs that open new fields, to processing units that separate oil, gas, and produced water, to storage tanks that hold thousands of cubic feet of product before transport.

Common equipment in gas operations includes:

- Oilfield equipment: production units, tanks, and pumping systems

- Gas processing equipment: separators, compressors, and control panels

- Gas field machinery: drilling rigs, pumps, and communal equipment lists that support shared operations

- Storage tanks: designed to hold crude oil, produced water, or natural gas liquids

When any of these systems fail, gas operations can grind to a halt. Extending their lifespan is about maintaining reliable production and protecting operator safety.

Average Service Life of Common Gas Equipment

| Equipment Type | Average Service Life (Years) | Notes on Longevity |

|---|---|---|

| Storage Tank | 20–30 | Coating quality and exposure to produced water matter |

| Separator | 15–20 | Dependent on maintenance and pressure levels |

| Compressor | 10–15 | Bearings and seals wear quickly without service |

| Pump | 8–12 | Highly dependent on fluid quality and flow rate |

| Control Panel | 10–15 | Sensitive to dust, heat, and electrical surges |

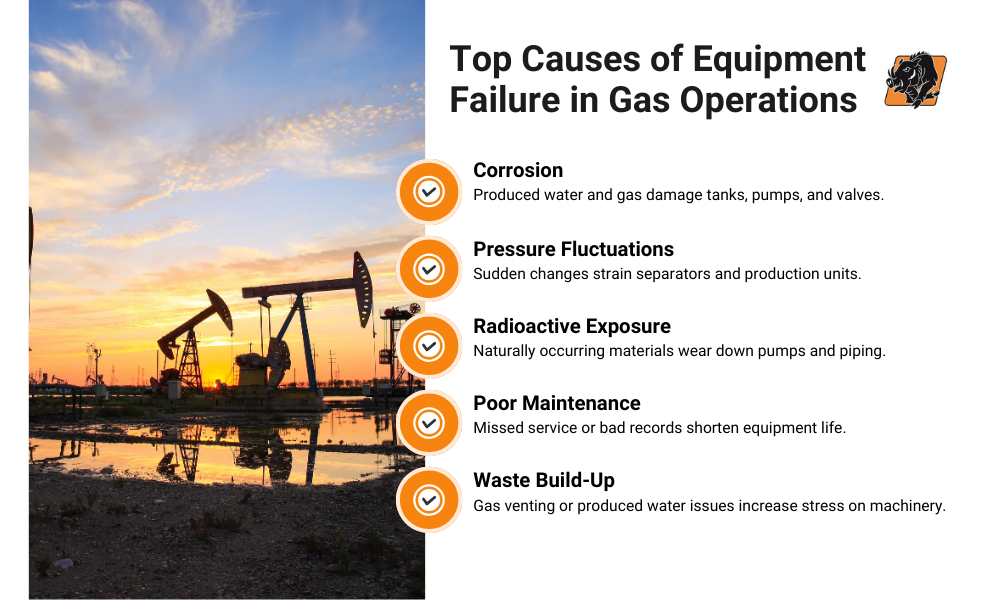

Common Causes of Equipment Failure in Gas Fields

Understanding why equipment breaks down is the first step toward preventing it. Failures often start small, often a worn seal, a change in differential pressure, or a buildup of produced water, and then spread into larger problems if left unchecked. By knowing the most common failure points, operators can focus maintenance efforts where they matter most.

Top causes of equipment failure in gas operations:

- Corrosion – Produced water and corrosive gas can eat away at tanks, pumps, and valves.

- Differential Pressure Fluctuations – Sudden changes put strain on separators and production equipment.

- Exposure to Radioactive Material – Handling naturally occurring radioactive substances can wear out pumps and piping.

- Improper Maintenance – Skipped service intervals or poor recordkeeping lead to premature wear.

- Gas Waste Build-Up – Uncontrolled gas venting or improper produced water handling increases strain on machinery.

Failure often doesn’t happen overnight. Small problems build over time until they lead to costly downtime. By spotting the warning signs early and acting quickly, operators can keep production equipment in service much longer.

Preventative & Predictive Maintenance Strategies

Maintenance is the foundation of equipment longevity. Both preventative and predictive approaches help operators avoid expensive shutdowns.

Preventative Maintenance

Preventative steps are scheduled and routine. They include:

- Regular inspections of pumps, valves, and tanks

- Lubrication of moving parts

- Filter replacements in compressors and separators

- Calibration of control equipment

Predictive Maintenance

Predictive maintenance uses data and monitoring tools to identify problems before they cause downtime. Examples include:

- Tracking differential pressure across separators

- Using vibration analysis on pumps and compressors

- Applying thermal imaging to electrical systems

- Remote monitoring systems that track performance in real time

Maintenance Frequency Recommendations

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual inspection of tanks | Daily | Check for leaks, corrosion, and fluid buildup |

| Lubrication of pumps | Weekly | Extend bearing and seal life |

| Calibration of control units | Monthly | Maintain accurate readings |

| Full equipment audit | Annually | Replace worn parts, review service history |

Equipment Repair vs. Replacement

Every operator faces the same question: Do we repair or replace this equipment? The decision carries major financial and operational weight, as repairs can extend service life at a lower cost, while replacement often delivers longer-term reliability and compliance with updated standards. Choosing the right path depends on the condition of the equipment, availability of parts, and the impact downtime will have on gas production.

When Repair Makes Sense

- Damage is limited to a single component, such as a pump seal or valve

- Replacement parts are readily available

- Service technicians can complete repairs with minimal downtime

When Replacement Is Smarter

- Equipment failure is widespread across multiple systems

- Repair costs exceed 50% of the replacement cost

- Older equipment lacks advanced features for modern gas operations

- Regulatory requirements call for upgrades

Repair vs. Replacement Comparison

| Factor | Repair | Replacement |

|---|---|---|

| Initial Cost | Lower | Higher |

| Downtime | Short (hours to days) | Longer (days to weeks) |

| Long-Term Reliability | May be limited | Greater lifespan |

| Safety & Compliance | May not meet new regulations | Built for current standards |

| Operational Efficiency | Maintains status quo | Improved with modern technology |

Upgrading to Modern Equipment with Advanced Features

Upgrading means investing in equipment built from the start for durability, reliability, and long service life. While the upfront cost can be higher, modern oilfield and gas processing equipment is built to deliver consistent performance for years.

Modern upgrades include:

- Storage tanks with advanced coatings that resist produced water damage

- Automated control equipment for real-time monitoring of flow, temperature, and differential pressure

- Produced water handling systems that reduce corrosion and waste buildup

- Gas processing equipment designed with better materials and longer-lasting parts

EZG Manufacturing builds custom oil and gas processing equipment with durability in mind. Our machines are designed for the unique needs of gas fields, processing plants, and oilfield operations.

Regulatory and Safety Considerations

Oil and gas facilities operate under strict regulatory requirements. Extending equipment life also means consistently meeting these standards.

Examples of regulations that impact equipment longevity:

- Handling and disposal of produced water

- Monitoring for radioactive material in gas waste

- Public comment periods for new equipment installations

- Inspection and reporting requirements for tanks and gas facilities

Safety Practices for Operators

Safety in oil and gas operations depends heavily on how equipment is handled day to day. Service technicians should be trained not only to operate machinery but also to carry out regular maintenance and repair work correctly. Keeping accurate, up-to-date records of inspections and part replacements helps operators track wear patterns and spot problems early. Protective coatings should be used wherever possible to guard tanks, pumps, and piping against damage from produced water and other harsh elements. Finally, scheduling downtime for planned maintenance before equipment failure occurs allows operators to control production schedules rather than react to unexpected shutdowns.

How EZG Manufacturing Supports Longevity in Oil and Gas Equipment

At EZG Manufacturing, we know the challenges operators face in oil and gas production, and our goal is to build equipment that lasts. We manufacture custom solutions for oil fields, gas processing facilities, and storage operations.

From storage tanks to production equipment, our solutions support reliable operations. By focusing on trust, durability, and problem-solving, EZG partners with gas companies to deliver equipment that stands up to the demands of daily operation and keeps production moving safely.