Consistency is everything when it comes to masonry mortar. A strong, uniform mortar mix is the foundation of any masonry project. Uneven batches can lead to weak joints, structural issues, and costly repairs later on. Fortunately, achieving a consistent mix doesn’t have to be complicated. By following proper techniques and using the right equipment, you can produce reliable mortar every time.

Why Consistency in Masonry Mortar Matters

Mortar does more than hold masonry units together. It provides bond strength, distributes loads, and maintains water resistance within a wall system. When mortar is inconsistent, its performance suffers. Weak areas may form, creating voids that compromise compressive strength and durability.

Uneven mortar also affects water retention and setting time. If water is unevenly distributed, some joints may dry too quickly, reducing adhesion. Others may stay too wet, causing shrinkage or cracking later on. Over time, these issues can impact both the appearance and stability of masonry structures.

Common Causes of Uneven Mortar Batches

Incorrect Material Ratios

One of the most common problems is an inaccurate mix of Portland cement, masonry cement, lime, and sand. Each type of mortar—Type N, S, or M—has a specific ratio for a reason. A Type N mix, commonly used for general purpose work, has a different proportion of lime and cement compared to Type S, which is made for higher-strength applications like load-bearing walls. Skipping accurate measurement leads to unpredictable performance.

What’s the difference between Type N, S, and M mortar?

The type of mortar you choose affects the strength and flexibility of the finished structure:

- Type N: Medium-strength, suitable for general use in non-load-bearing walls and chimneys.

- Type S: Stronger than Type N, commonly used for exterior walls, patios, and load-bearing walls.

- Type M: The highest strength option, designed for heavy-duty applications like foundations and retaining walls.

Knowing which type to use helps maintain proper compressive strength and bonding in masonry structures.

Inconsistent Water Content

Water content is one of the most influential factors in mortar quality. Too much water results in a weak, runny mortar with poor bond strength. Too little water makes mortar stiff and unworkable. Both extremes affect compressive strength, setting time, and overall bonding.

What happens if mortar is too wet or too dry?

If mortar is too wet, it can lose strength, set slowly, and sag or run on the wall. This weakens adhesion and leads to cracks during drying. If it’s too dry, the mortar becomes hard to spread and won’t properly bond with masonry units, creating weak joints and gaps.

Manual Mixing Limitations

Hand-mixing or using small tools often produces uneven blends. Clumps of cement mortar and dry pockets of sand can remain in the mix, leading to unpredictable results on site. Manual mixing also consumes more time and energy, increasing the chances of operator error.

How to Achieve a Consistent Mortar Mix

Consistency starts with preparation and proper technique. Here are the most important steps to follow for achieving reliable, uniform mortar on every project:

Follow Standard Specifications

Start with ASTM C270, the Standard Specification for Mortar for Unit Masonry. This guideline outlines performance requirements such as compressive strength, bonding properties, and water retention. It also includes recommendations for mixing proportions based on the type of mortar and the intended application.

By following these guidelines, you reduce variability and produce mortar that meets structural and durability requirements. Contractors often consider this the industry benchmark because it creates predictable, repeatable results in the field.

Use Quality Materials

The strength and workability of mortar depend heavily on the different materials you use:

- Sand: Choose clean, well-graded masonry sand. Contaminated or oversized particles can disrupt bonding and create weak points.

- Cement: Portland cement and masonry cement should be fresh and properly stored to avoid clumping or premature hydration.

- Lime Mortar: Hydraulic lime improves workability and water retention. Check that lime is compatible with your chosen mortar type.

- Water: Always use potable water. Dirty or mineral-heavy water can affect setting time and bond strength.

Avoid damp or contaminated aggregates at all costs. Excess moisture in sand, for example, throws off your water-to-cement ratio and leads to inconsistent batches.

Measure Accurately

Guessing material quantities leads to inconsistent results. Weigh ingredients when possible and stick to established mix ratios for your mortar type. Remember that each mortar type requires a different ratio.

Control Water Content

Water plays a major role in determining workability and strength. Adding too much water produces a soupy, weak mortar that shrinks and cracks as it dries. Too little water makes mortar stiff and hard to spread, leading to poor adhesion and gaps.

Here’s how to manage water content effectively:

- Add water slowly, in small increments, during mixing.

- Check the mix frequently instead of pouring all the water at once.

- Adjust for jobsite conditions—hot, dry weather often requires slightly more water to compensate for evaporation.

How Long Should Mortar Be Mixed?

Mortar should be mixed for 3–5 minutes after adding water. This period allows cement particles to fully hydrate and the materials to blend uniformly. Mixing for less time can leave dry clumps or uneven material distribution, while over-mixing may introduce too much air, reducing compressive strength.

Pro Tip: After mixing, let the mortar rest for a minute, then remix briefly before application. This short “resting phase” improves workability and bonding.

How do I check mortar workability on site?

Two simple field tests can help confirm consistency before applying mortar:

- Flow Table Test: Place a mortar sample on the flow table and measure its spread after being dropped several times. This provides a numeric value for workability.

- Slump Test: Shape a small cone of mortar, remove the mold, and measure how much it slumps. Excessive slump means the mix is too wet; no slump means it’s too dry.

A workable mortar should hold its shape while being easy to spread with a trowel. If the mix is too stiff, add water in small increments and remix. If it’s too loose, add dry material and mix again.

The Role of Equipment in Consistent Mixing

Why Mechanical Mixing Works Best

Mechanical mixers outperform manual methods almost every time. They deliver uniform blending, reduce physical strain, and help maintain consistency batch after batch.

How EZG Mud Hog® Mixers Solve the Problem

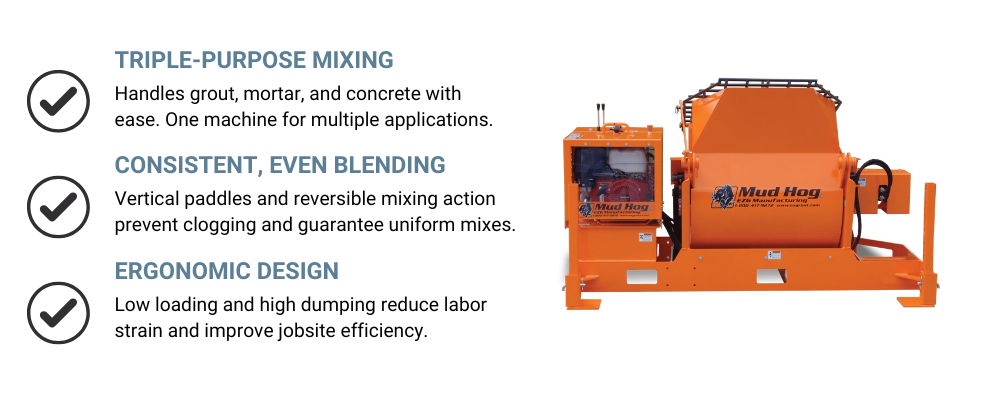

EZG Manufacturing’s Mud Hog® hydraulic mixers are engineered for demanding masonry jobs.

Designed to handle grout, mortar, and concrete, they combine durability with smart design for consistent results. Here’s why contractors trust Mud Hog® mixers:

- Vertical paddle design for even blending and minimal splashing.

- Reversible mixing paddles to prevent clogging and maintain a smooth mix.

- Hydraulic drive and dump for precise control.

- Low loading and high dumping for ergonomic operation.

- Compact build that fits into a standard 8′ truck bed, making transport simple.

Additional features like adjustable legs, fork pockets, and enclosed lids for dust control make these mixers practical and reliable for jobsite use.

Build Stronger with EZG

Producing uniform mortar is all about accuracy, proper mixing, and the right tools. EZG Manufacturing’s Mud Hog® mixers are designed to simplify the process, giving masons a reliable way to achieve consistent, high-quality results.

Ready to improve your mix? Explore the full line of Mud Hog® Mixers from EZG Manufacturing and take the guesswork out of masonry mortar.